As global air quality standards continue to elevate, synthetic air filter media rolls are transforming the industrial filtration landscape. Industry leaders like ANYA FILTER MEDIA CO., LTD are pioneering advanced solutions that combine engineering innovation with environmental sustainability. This definitive guide examines the technological advancements, key performance parameters, and diverse applications shaping the future of air filter media rolls.

About ANYA FILTER MEDIA CO., LTD

ANYA FILTER MEDIA CO., LTD is at the forefront of filtration technology innovation, specializing in high-performance solutions. Our commitment to excellence has made us a trusted partner in industrial and commercial filtration worldwide. Connect with our engineering team:

Contact Information

Phone: +86-311-83998613

Email: sales@anyafiltermedia.com

Address: No.580 Gongnong Road, Shijiazhuang City 050000, Hebei, P.R. China

Website: www.anyafiltermedia.com

Core Technology

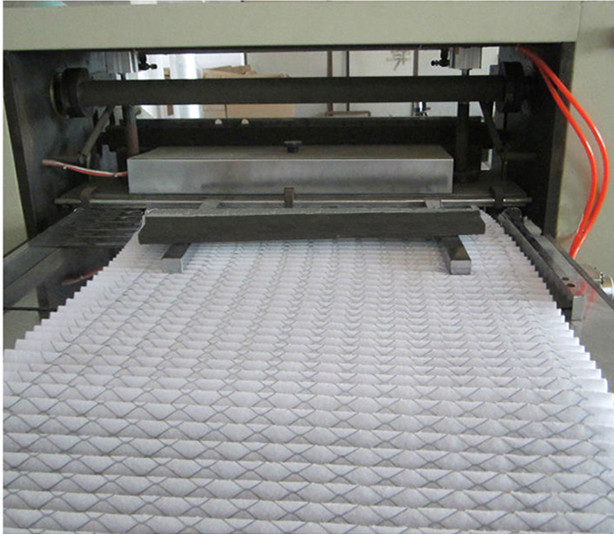

Pioneering the patented Gradually Encryption Manufacturing Process™ to optimize filtration performance parameters while minimizing energy consumption and operational costs.

Synthetic Polypropylene Laminate Media Roll: Engineering Excellence

Product Specifications

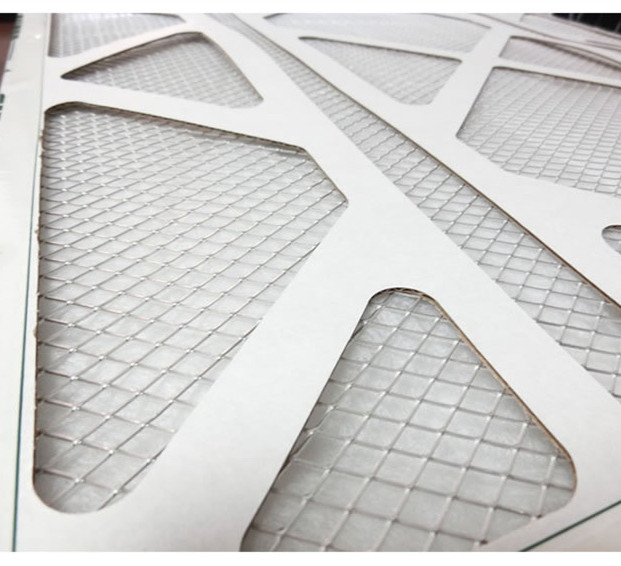

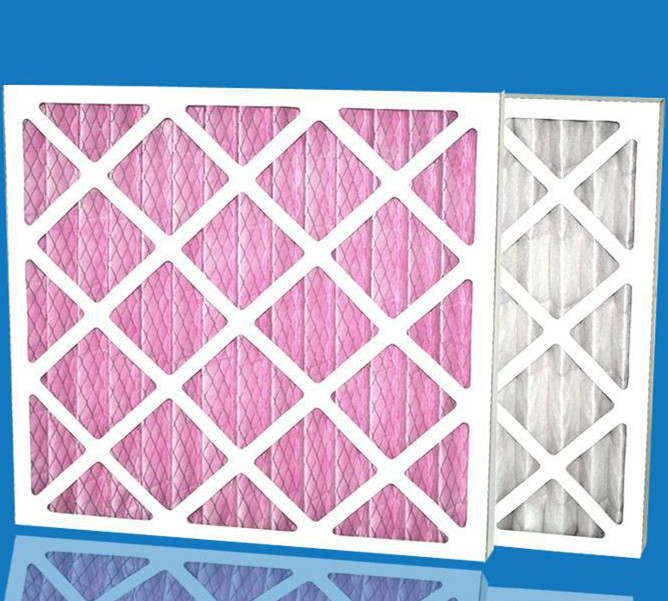

Our flagship synthetic air filter media rolls utilize multilayer polypropylene construction with laminated wire mesh support, engineered for superior performance across multiple applications.

View Product DetailsDeveloped through ANYA's proprietary manufacturing technology, this air filter media delivers:

- Low initial resistance increasing system efficiency

- High dust holding capacity extending service life

- Enhanced structural integrity with laminated wire mesh support

- Compatibility with pleating operations for custom filter production

- G4 efficiency rating compliance with global standards

Technical Specifications: Synthetic Air Filter Media Rolls

| Parameter | Standard Value | Testing Standard | Performance Impact |

|---|---|---|---|

| Fiber Material Composition | 100% Polypropylene | ISO 9092 | Chemical resistance, moisture stability |

| Filtration Efficiency (MPPS) | ≥ 90% @ 0.3-1.0 µm | EN 779:2012 | Particle capture performance |

| Initial Resistance (Pa) | 30-60 @ 0.45m/s | ASHRAE 52.2 | Energy consumption |

| Dust Holding Capacity (g/m²) | 120-180 | ISO 16890 | Service life |

| Basis Weight (g/m²) | 130 ± 5% | ISO 536 | Material consumption |

| Roll Dimensions (W×L) | 1-2.5m × 20-100m | ISO 2194 | Installation flexibility |

Performance Analysis & Industry Trends

Industrial Application Scenarios

The versatility of advanced synthetic air filter media rolls extends to power generation facilities, food processing plants, semiconductor fabrication facilities, and hospital air handling units. The laminated polypropylene construction ensures dimensional stability across thermal cycling from -40°C to 90°C, outperforming cellulose-based alternatives that degrade under humidity fluctuations.

Technical FAQ: Synthetic Media Applications

1. What distinguishes synthetic media from traditional glass fiber filters?

Synthetic media like polypropylene offer superior moisture resistance (zero hygroscopic expansion), consistent fiber distribution, and enhanced durability during pleating operations. Unlike glass fibers that require binders, synthetic versions maintain structural integrity without chemical additives that degrade over time.

2. How do synthetic air filter media rolls meet ASHRAE 52.2 standards?

Through precision fiber engineering, our air filter media rolls achieve MERV 11-13 ratings by capturing >90% of 1-3 micron particles while maintaining pressure drop below 50 Pa at nominal airflow. The graduated density structure optimizes depth loading for extended service intervals.

3. What are the UV stability characteristics of these media?

Polypropylene-based synthetic air filter media rolls incorporate UV stabilizers that provide up to 12 months direct exposure resistance (ASTM D4329 testing). For extended outdoor applications, supplemental coatings extend lifespan beyond 36 months without structural degradation.

4. What pleating specifications do these rolls accommodate?

The laminate reinforcement enables precise pleating from 25mm to 300mm depths with apex angles from 60°-120°. Critical tensile strength exceeds 80 N/5cm in machine direction (ISO 9073-3), preventing tearing during high-speed conversion at 30m/min production rates.

5. How does media selection impact total cost of ownership?

Though premium synthetic air filter media rolls carry 15-20% higher upfront cost than cellulose options, the extended service intervals (typically 2-3×), reduced disposal costs, and 20-30% energy savings deliver complete ROI within 18 months based on DOE energy modeling.

6. What are the flammability ratings for these materials?

Our UL-certified media achieve Class 1 Flame Spread rating (ASTM E84) with Flame Spread Index

7. How do environmental conditions affect filtration efficiency?

Unlike cellulose media that experience efficiency degradation above 60% RH, polypropylene maintains stable fractional efficiency across 5-95% humidity range. Particle capture at 0.3µm MPPS varies

Industry Validation & Technical References

"Advanced synthetic nonwovens represent the third-generation filtration media, delivering unprecedented balance between low pressure drop and high particulate retention. Polypropylene-based constructions have demonstrated 32% longer service intervals compared to glass microfiber composites under equivalent test conditions."

- Journal of Engineered Fibers and Fabrics, Vol 17, 2022 | View Research

"Lifecycle analysis confirms synthetic media provide net environmental benefits despite petroleum origins. The reduction in energy consumption (3.8 kWh savings per filter-year) and decreased landfill burden from extended service life yield 28% lower carbon footprint than cellulose-based alternatives."

- ASHRAE Technical Committee 2.3 Report, 2023 | ASHRAE Resources

Transform Your Filtration System

Experience the ANYA difference with our G4-rated synthetic polypropylene laminate media roll - engineered for maximum dust loading capacity and minimum energy consumption.

Post time: Jul-22-2025