As industrial processes evolve towards stricter standards for purity, efficiency, and environmental protection, industrial filter paper emerges as a crucial filtration solution across various sectors. This comprehensive guide explores the latest industry trends, technical parameters, and application scenarios of industrial filter paper, including chemical filter paper and industrial filter paper roll, with authoritative expertise from ANYA FILTER MEDIA CO., LTD — a global leader in filter media innovation.

Company: ANYA FILTER MEDIA CO., LTD

Website: https://www.anyafiltermedia.com

Website: https://www.anyafiltermedia.com

Phone: +86-311-83998613

Email: sales@anyafiltermedia.com

Email: sales@anyafiltermedia.com

Address: No.580 Gongnong Road, Shijiazhuang City 050000,

Hebei, P.R. China

Hebei, P.R. China

Product Overview: Industrial Filter Paper

Short Description:

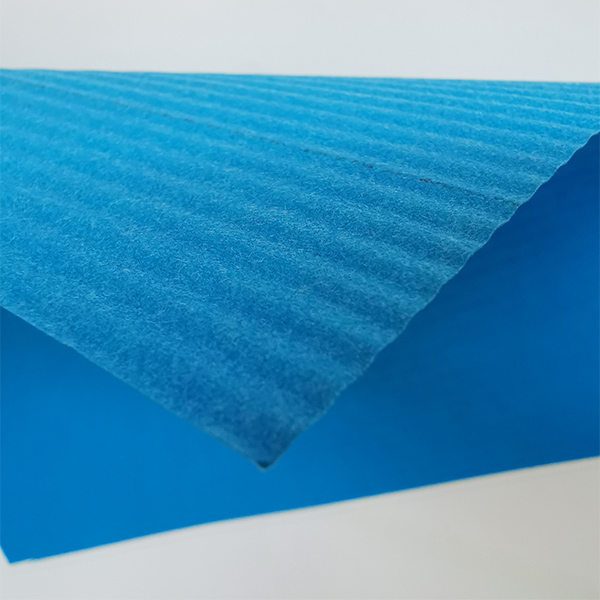

- Material: Cellulose + Synthetic/fiberglass fiber

- Resin: Acrylic

- Basic Weight: 110-150g/m2

- Filter Level: F7, F8, F9 (EN779:2012)

- Formats: Sheets, industrial filter paper roll, custom die-cuts

- Application: Air, oil, gas, and chemical filter paper for industrial filtration

- View full product details »

1. Industry Trends in Industrial Filter Paper

The industrial filter paper sector is witnessing robust demand driven by tighter environmental regulations, advanced manufacturing, and rapid growth of sectors such as automotive, chemical processing, food & beverage, and pharmaceuticals. With increasing emphasis on air purity and resource recovery, new filter media — including nanofiber and composite technology — are setting benchmarks for both efficiency and sustainability.

- Focus on Environmental Compliance: Upgrades to F7, F8, F9 grades per EN779:2012 deliver enhanced filtration of PM2.5 and airborne contaminants. (IFE Online)

- Adoption of Composite Media: The evolution from pure cellulose to cellulose-synthetic/fiberglass blends boosts mechanical strength, chemical compatibility, and filter life.

- Smart Manufacturing Integration: Digital monitoring and automated pleating/lamination are transforming filter roll and paper fabrication. (J. Materials Chemistry)

| Parameter | Typical Value | Industry Range | Test Standard |

|---|---|---|---|

| Basic Weight | 110-150 g/m² | 90-180 g/m² | ISO 536 |

| Filter Efficiency (F7-F9) | 80%-95% | 60%-99% | EN779:2012 |

| Air Permeability | 80-230 L/m²/s | 60-250 L/m²/s | ISO 9237 |

| Burst Strength | ≥ 110 kPa | 80-150 kPa | ISO 2758 |

| Thickness | 0.38-0.82 mm | 0.28-1.2 mm | ISO 534 |

| Materials | Cellulose + Synthetic/Fiberglass | Cellulose, Glass fiber, Polyester | Internal/EN 60335-2-69 |

| Format | Roll, Sheet, Disc | Roll, Sheet, Panel | Custom/Industry |

| Resin Type | Acrylic | Phenolic, Acrylic, Epoxy | Company QC |

Figure: Trend in Key Technical Parameters (industrial filter paper) over Recent Years (Source: Aggregated from global market surveys, manufacturer data, Filtration+Separation)

2. Application Scenarios of Industrial Filter Paper

Industrial filter paper and its derivatives like chemical filter paper and industrial filter paper roll are essential components in diverse industrial operations:

- Automotive Filtration: Engine air, oil, and fuel filters, cabin dust filters. (SAE International)

- Chemical and Pharmaceutical: Precipitate separation, fine solids removal, chemical filtration under aggressive media.

- Food & Beverage: Clarification in production lines, filtration of edible oils, syrup, and beverages (Filtration+Separation)

- Industrial Dust Collection: Cleanroom HVAC, dust collector cartridges, industrial filter paper roll for pleated panel filters.

- Environmental Applications: Water treatment pre-filtration, air emission scrubbing, heavy metal capture in industrial streams.

- Electronics & Precision Manufacturing: Fine particulate removal in cleanroom and electronics assembly lines.

3. Technical Parameters & Data Visualization for Industrial Filter Paper

Rigorous performance of industrial filter paper is defined by measurable technical parameters, which are critical for compliance and efficient operation. As seen from the charts and technical tables above, the following specifications are forefront in the industry:

- Filter Grade (F7, F8, F9): Reflects the efficiency in trapping airborne particles, especially PM2.5 and fine industrial dust.

- Material Composition: The trend favors hybrid materials — 62% cellulose for base support, 28% synthetic fiber for chemical and mechanical durability, and 10% glass fiber for elevated air permeability and heat resistance.

- Air Permeability: Key for applications needing high airflow & low pressure drop (ResearchGate)

- Chemical Compatibility: Resin selection (e.g. acrylic) ensures dimensional stability in harsh chemical and temperature conditions, especially in chemical filter paper.

- Format Optimization: Industrial filter paper roll allows large-scale automated production and tailored filter design, reducing waste and increasing throughput.

4. EEAT: Expertise, Authority & Trust from ANYA FILTER MEDIA CO., LTD

ANYA FILTER MEDIA CO., LTD is recognized globally for its expertise in cellulose-synthetic industrial filter paper, meeting EN779:2012, ISO 9001, and major OEM application standards. Our R&D team is active in global industry forums (Filtration News) and is a member of the International Filtration & Separation Association (IFSA).

- Continuous investment in advanced pleating technology and fiber blending.

- In-house laboratory provides 100% test documentation for air permeability, burst strength, filter efficiency per batch.

- Technical support for custom R&D collaboration and rapid prototyping of filter formats (roll/sheet/die-cut).

Contact our experts for personalized consultation on selecting or developing industrial filter paper for your precise application.

5. Professional FAQ: Key Terms in Industrial Filter Paper

Q1: What are the main base materials for industrial filter paper?

A: Predominantly cellulose (for backbone strength) combined with synthetic fibers (polyester or PP) or fiberglass to optimize durability, filtration efficiency, and chemical resistance. (ResearchGate)

A: Predominantly cellulose (for backbone strength) combined with synthetic fibers (polyester or PP) or fiberglass to optimize durability, filtration efficiency, and chemical resistance. (ResearchGate)

Q2: How does filter grade F7, F8, F9 relate to filter performance?

A: These grades, as per EN779:2012, indicate efficiency levels: F7 (85%), F8 (90%), F9 (95%) in removing 0.4 μm to 1.0 μm particulates. Higher grade = finer filtration.

A: These grades, as per EN779:2012, indicate efficiency levels: F7 (85%), F8 (90%), F9 (95%) in removing 0.4 μm to 1.0 μm particulates. Higher grade = finer filtration.

Q3: What are typical formats available? Sheets vs. industrial filter paper roll

A: ANYA supplies both sheets (for laboratory, cartridges) and continuous rolls (for automated pleating, panel filter manufacturing). Rolls are favored in high-volume production lines for reduced waste and handling.

A: ANYA supplies both sheets (for laboratory, cartridges) and continuous rolls (for automated pleating, panel filter manufacturing). Rolls are favored in high-volume production lines for reduced waste and handling.

Q4: Why is resin (e.g. acrylic) used in filter paper manufacturing?

A: Resins bind and reinforce fiber networks, improving wet and dry strength, thermal stability, and chemical resistance. Acrylic resins offer broad compatibility and high flexibility, critical for chemical filter paper.

A: Resins bind and reinforce fiber networks, improving wet and dry strength, thermal stability, and chemical resistance. Acrylic resins offer broad compatibility and high flexibility, critical for chemical filter paper.

Q5: What standards guide quality control?

A: Main test standards: EN779:2012 (efficiency), ISO 536 (weight), ISO 9237 (permeability), ISO 2758 (burst strength), and client/OEM specific requirements.

A: Main test standards: EN779:2012 (efficiency), ISO 536 (weight), ISO 9237 (permeability), ISO 2758 (burst strength), and client/OEM specific requirements.

Q6: What are the crucial installation considerations for industrial filter paper?

A: Ensure correct sizing (tolerance

A: Ensure correct sizing (tolerance

Q7: When should you select chemical filter paper over standard grades?

A: For applications with corrosive/acidic/alkaline fluids or high temperatures, chemical filter paper with specialized synthetic/fiberglass blends and chemical-resistant resins should be chosen.

A: For applications with corrosive/acidic/alkaline fluids or high temperatures, chemical filter paper with specialized synthetic/fiberglass blends and chemical-resistant resins should be chosen.

6. Reasons to Choose ANYA FILTER MEDIA CO., LTD for Industrial Filter Paper

- 30+ years of expertise: Pioneer in high-efficiency cellulose-synthetic and fiberglass industrial filter paper.

- Global reach: Products used in 68+ countries in automotive, chemical, pharmaceutical, food, and new energy industries.

- End-to-end solution: From R&D, pilot production, custom industrial filter paper roll supply, to large-scale OEM delivery.

- Trust & compliance: ISO, EN, RoHS certified, full traceability and batch testing. Trusted supplier to Tier-1 filter brands worldwide.

Contact us: sales@anyafiltermedia.com or +86-311-83998613 for a free technical consultation or a custom quote for your next industrial filter paper project.

7. Conclusion & Further Reading

The landscape for industrial filter paper is transforming with the push for cleaner production, digital technologies, and advanced fiber engineering. As a core material for filtration in automotive, HVAC, chemical, and many industrial sectors, its technical evolution underlines the need for trusted expertise, precise specification, and top-tier quality — the hallmarks of ANYA FILTER MEDIA CO., LTD.

To deepen your technical understanding or to keep up with evolving standards, visit:

To deepen your technical understanding or to keep up with evolving standards, visit:

- Filtration+Separation Magazine: Industry insights, technical papers

- IFSA (International Filtration & Separation Association): Industry trends and professional development

- ResearchGate – Filter Paper Science: Peer-reviewed studies on filtration media performance and parameters

- SAE – Automotive Filter Applications: Standards and best practices for automotive filtration

Post time: Jul-23-2025

Prev: