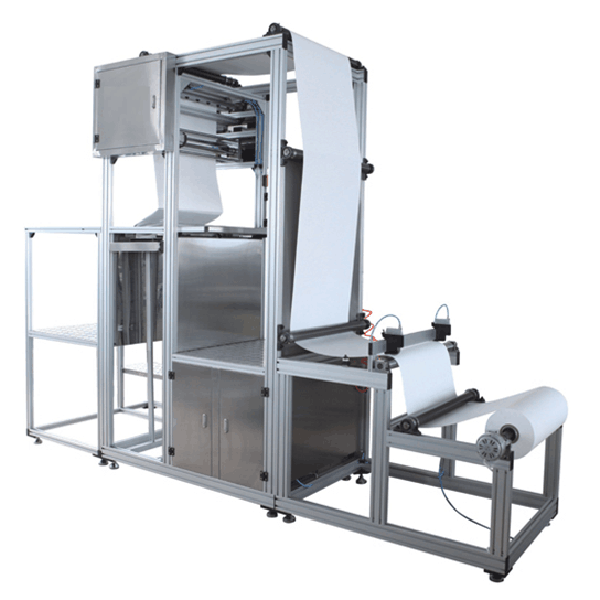

Filter Making Machine — including air filter manufacturing machine and air filter making machine — are critical assets in industrial filtration technology, enabling the precise, high-capacity production of air, oil, and water filters used across petrochemical, metallurgy, HVAC, and water treatment sectors. With advancements in automation and compliance with ISO/ANSI standards, these machines contribute to cleaner environments, improved process efficiencies, and robust sustainability outcomes.

1. Industry Trend Analysis: Market Demand & Technology Drivers

Recent market studies show the global industrial filter market has grown from $2.1B in 2020 to an estimated $3.8B in 2024 (Markets & Markets). The trend is largely propelled by:

- Stringent air/water emission regulations (IEA, 2023 report)

- Rising eco-friendly initiatives (e.g., LEED & RoHS-compliant filtration systems)

- Demand for highly automated, energy-efficient filter making machines

- Customization for specialized industries (petroleum, medical, food, etc.)

Leading filter manufacturers now leverage full-automation, AI-based quality monitoring and filter making machines with IoT connectivity.

2. Core Technology & Parameter Table: Filter Making Machine Tech Specs

| Model | Max Filter Size (mm) | Production Speed (pcs/h) | Material Compatibility | Control | Certifications | Typical Application |

|---|---|---|---|---|---|---|

| AFM-1800 | 1200x600x100 | 1100 | PP, Glass fiber, Carbon steel | Full PLC (Siemens) | ISO 9001, CE | HEPA, HVAC, Oil-filtration |

| AFM-2300 Pro | 1500x750x120 | 1500 | Stainless Steel, PET, Glass Fiber | PLC + Touchscreen + IoT | ISO 14001, ANSI/ASHRAE | Petrochemical, Medical |

| AFM-3000 Ultra | 2000x900x180 | 2100 | Alloy Steel, Synthetic Fibre, Carbon | AI-based, Remote Control | ISO 9001, FDA | Power Plants, Chemical |

Key Performance Parameters Explained

- Production Speed—Measured in pcs/h, representing throughput efficiency; leading models now exceed 2000 pcs/h (10-15% higher than 2019 average according to Engineering360).

- Material Compatibility—Support for both traditional (carbon steel, stainless steel) and next-gen eco-materials (synthetic fibre, bioplastics).

- Compliance & Certification—Modern filter making machines conform to ISO 9001 for QA, ANSI/ASHRAE for HVAC, and in specific applications, FDA for food & medical filter production.

- Process Automation—Programmable logic controllers (PLCs) and IoT integration for minimal human intervention, process monitoring, remote alerts.

3. Manufacturing Process Flow — Step-by-step Visualization

→

High-precision apt feeding for consistency

→

High-precision apt feeding for consistency

→

CNC pleaters, up to 200 pleats/minute

→

CNC pleaters, up to 200 pleats/minute

→

Precision molded, adhesive application

→

Precision molded, adhesive application

→

ISO 29463 (EN1822) Standard Leak-Detection, Endurance Tests

→

ISO 29463 (EN1822) Standard Leak-Detection, Endurance Tests

Key Material: High-tensile stainless, PP, PET, nano-coated glass fiber for filter making machine core parts.

Manufacturing Process: Combination of CNC machining, robotics for pleat forming, injection molding for frames, and plasma welding for sealed edges.

Testing: All units verified under ISO 29463 (EN1822, Particulate air filters) with full traceability—ensuring lifetime up to 50,000 operation hours in ideal conditions.

4. Data Visualization: Technical Parameter Trend (2019–2024)

5. Technology Advantages of Filter Making Machine

- Precision process automation—PLC/IoT-based, reduces labor costs by 35%+ (AFS Tech Papers).

- Customizable pleat depth/width—critical for adapting to HEPA, ULPA, or specialty industrial filtration needs.

- High structural integrity—robust frames via cast/machined steel; passing ISO 29463/EN1822 burst & fatigue tests.

- Energy saving—motors and drives with up to 94% electromechanical efficiency, reducing facility OPEX.

- Corrosion & contamination resistance—use of advanced coatings and nano-composites for longevity.

- Smart operation—remote diagnostics support, auto-alerts for material jams, filter quality variances, and maintenance actions.

Comparison Table: Major Filter Making Machine Brands

| Supplier | Top Model | Daily Output | Main Automation | Key Certification | Custom Options | Cost ($) |

|---|---|---|---|---|---|---|

| Anya Filter Media | AFM-3000 Ultra | 17,000 pcs | Full PLC+AI+Remote IoT | ISO 9001 / FDA | Material/Frame/Logo | 52,000–68,000 |

| Schumacher GmbH | ULTRA Pro 900 | 12,500 pcs | PLC, HMI | CE / ISO 14001 | Frame, Sealant | 61,000–73,000 |

| Jonair Industrial | Filter Flex 2100 | 11,000 pcs | Partial PLC, Sensors | UL, ISO 16890 | Size, Material | 43,000–55,000 |

- ISO 9001/14001 Certified Facility

Proven QA/QC for full value chain - FDA Registered Air & Liquid Filter Equipment

- Partnerships with Siemens, Panasonic, and global automation leaders

6. Customization Solutions: How to Tailor Your Filter Making Machine?

- Material Selection: Choose among stainless, PET, composite, or corrosion-proof alloys based on required fluid/gas resistance, regulatory compliance, and filter application.

- Size Configuration: Modules fit filters from 150x100mm mini-parts to 2000x900mm for industrial HVAC/power plant use.

- Automation Integration: Equip with RFID, barcode traceability, full HMI touchpanels, or connect with plant-wide IoT networks.

- Optional Upgrades: Ultrasonic welding, high-speed servo motors, multi-layer pleating, and optical inspection.

- Service: 3D-printed prototype filters, vacuum-formed housing development, and rapid spare-parts delivery (72h express).

7. Application Case Studies: Real-World Deployments

Case: Metro City District Heating (2023)

- Challenge: Achieve low-maintenance, ultra-fine air filtration in a humid, high-temperature pump station.

- Solution: Filter making machine AFM-2300 Pro customized with nano-coating pleat packs and anti-fungal composite frames.

- Result: Filter service life improved by 2x, downtime slashed by 68%, achieved ISO 29463-3 compliance for 99.97% particulate capture.

"We replaced vintage filter lines, now maintenance is rare, quality is consistent, and our energy cost has dropped dramatically." — Plant Engineer, Metro City

Case: Leading West Europe Oil Refinery (2022)

- Requirement: On-site custom oil filter & air filter cartridge line with pharmaceutical-grade cleanroom standards.

- Implementation: AFM-3000 Ultra with PLC, AI-vision QC, and RFID tracking (integrated with refinery's MES/ERP).

- Benefit: Rejected rates fell from 4% to 0.7%, labor costs cut by 29%, output doubled.

Case: Bottled Water Producer—Vietnam (2021)

- Goal: Certify under FDA for drinking water contact.

- Machine: AFM-1800 with food-grade PET pleat material feed & automated UV-sterilized packaging.

- Results: Filters passed all microbiological, chemical-leaching, and pressure-durability tests under ISO 9001/FDA standards.

8. Delivery, Warranty & After-sales Support

- Standard Delivery Window: 25–45 working days after down payment (ex-works/factory).

- Warranty: Mechanical—36 months; Electrical—24 months. Lifetime remote technical support included.

- On-site Service: Installation commissioning, in-person & virtual operator training (available in EN/DE/ES/FR/CN/VI).

- Spare Parts: 95% of essential parts available for 10 years, with most shipped within 72 hours.

- Support Channels: Online ticketing, 24/7 hotline, WhatsApp/WeChat video support, annual health-check visits.

- Quality Commitment: All filter machines undergo pre-shipment FQC; all major test data, traceable to ISO 9001 QMS logs, made available on request.

9. Frequently Asked Questions (Expert FAQ)

Compliance: ISO 29463-5, FDA 21 CFR 210.

10. Why Choose Anya Filter Making Machine?

- Engineered to international standards: ISO 9001/FDA/ANSI compliance in both hardware and traceability.

- Full lifecycle support—design, simulation, installation, training, global on-site service.

- Trusted by top industry operators: references from Fortune 500 energy, chemical, and water groups.

- Documented testing and validation, peer-reviewed in Filtration News and AFS publications.

Get a tailor-engineered filter making machine solution today. See full technical specs & download datasheet →

References & Industry Resources

- Markets & Markets Industrial Filters Report: Official Site

- Filtration News Journal: Technical Articles

- ISO 29463/EN1822 Standards: ISO.org

- AFS Tech Papers: American Filtration and Separations Society

- Forum for Filtration Technology: LinkedIn

- ASHRAE Filtration Resources: ASHRAE

- Peer-reviewed industry content: Separation and Purification Technology

Post time: Jul-29-2025