As industries strive towards sustainability, energy efficiency, and high indoor air quality, non woven air filter media have emerged as a leading solution for advanced air filtration across diverse sectors. In this guide, we explore the latest industry trends, technical parameters, manufacturing flows, application scenarios, and real-world cases revolving around non woven fabric air filter and non woven media. Special focus is placed on Plastic Frame Air Filter Media, a key product in modern air filtration technology (click for product details).

Industry Trends & Market Outlook for Non Woven Air Filter Media

According to Grand View Research, the global non woven air filter media market size surpassed USD 3.1 billion in 2023 and is projected to grow at a CAGR of 6.2% from 2024 to 2030. Major drivers include the increased adoption in HVAC, automotive, food processing, and cleanroom industries. Key trends:

- Integration of synthetic fibers (polyester, polypropylene) for enhanced durability and dust holding capacity

- Customization for multi-stage filtration and anti-bacterial, anti-static functionalities

- Transition from glass fibre media to non woven fabric air filter media in medical and electronics due to safety and performance

- Smart filter monitoring using IIOT sensors for predictive maintenance

Technical Specifications of Non Woven Air Filter Media

To understand the performance of non woven air filter media, consider the following core technical parameters widely referenced by engineers, specifying bodies (ISO 16890, EN 779), and purchasers:

| Parameter | Typical Value | Unit | Spec Standard |

|---|---|---|---|

| Media Thickness | 0.8 - 5.0 | mm | ISO 9073 |

| Basis Weight | 80 - 550 | g/m² | ISO 9073 |

| Particle Filtration Efficiency | 35 - 99.9% | % | EN 779:2012 / ISO 16890 |

| Initial Pressure Drop (ΔP) | 30 - 120 | Pa | ISO 16890 |

| Dust Holding Capacity | 500 - 3500 | g/m² | Company Test |

| Temperature Resistance | Up to 120 | °C | Manufacturer Spec |

| Flammability Rating | UL 900 Class 2 | - | UL Standard |

Manufacturing Process Flow of Non Woven Air Filter Media

The creation of a high-performance non woven air filter media involves multiple precision engineering steps and quality checks to ensure the final product meets industrial-grade demands:

Polyester, Polypropylene, Bi-components

Carding, Airlaid, Wetlaid

Thermal Bonding, Needle Punching

Electrostatic, Anti-microbial, Flame Retardant

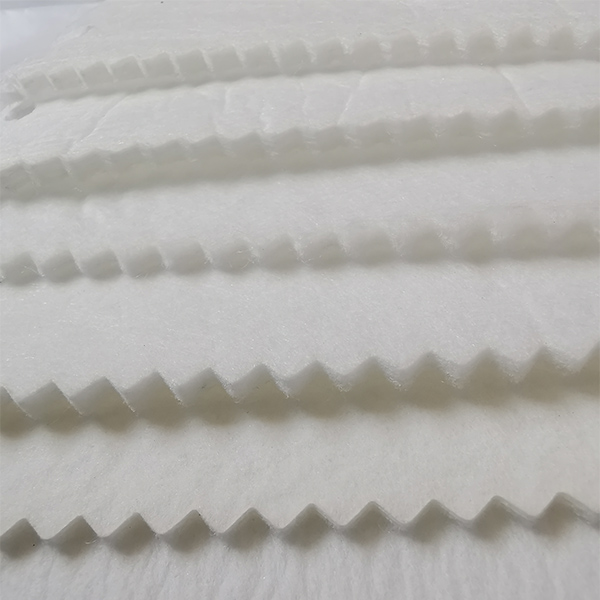

CNC Cutting / Pleating

ISO/EN, Particle Challenge, Pressure Drop

Note: For a real video demonstration of non woven air filter media production, visit Air Filter Media Manufacturing Video.

Material Science & Manufacturing Technology

- Material: Advanced synthetic non-woven fibers and blends offer low pressure drop, optimal filtration, mold resistance, and longevity.

- Technologies Used: Carding, meltblown, spunbond, needle-punch, and composite lamination for targeted highefficiency filtration zones.

- Precision CNC Cutting enables custom pleat design and maximizing surface area-to-volume ratio.

- Testing Standards: QC conforms to ISO 16890, EN 779:2012, and UL 900 requirements.

- Service Life: 6 months to 3+ years depending on specification and operation environment.

- Industries Served: HVAC, petrochemical, metallurgy, semiconductor, water & wastewater, food, and healthcare.

- Advantages: Lightweight, flexible, anti-corrosive, high holding capacity, flame retardant, customizable formats.

Product Overview: Plastic Frame Air Filter Media

- Product Name: Plastic Frame Air Filter Media

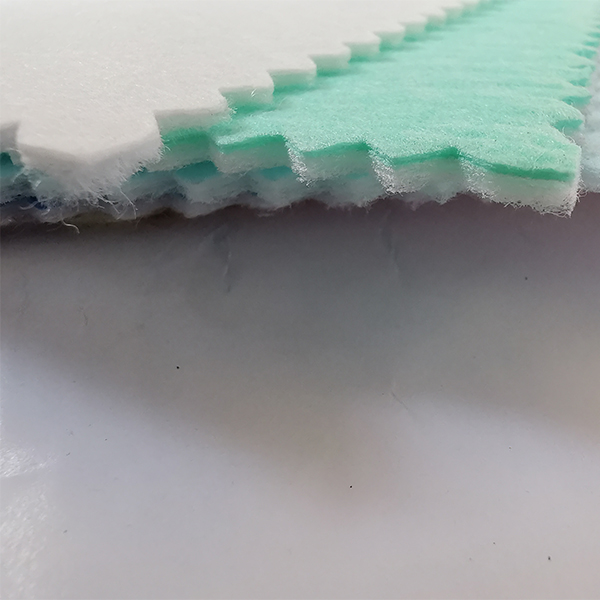

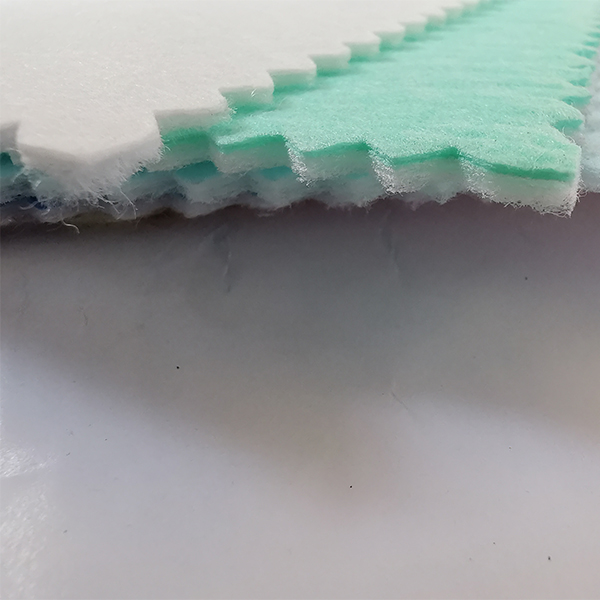

- Material: High-impact ABS/HDPE plastic frame + premium non woven fabric air filter media

- Size (mm): 290×592×20, 495×592×20, 595×595×25 or Custom

- Filter Class: ISO ePM2.5 65-95% / M5-F9 (EN 779)

- Initial Resistance: 35-70 Pa

- Recommended Airflow: 800-3200 m³/h

- Temperature Resistance: -20 to +80°C

- Frame: Seamless injection molding, anti-bacterial, corrosion-proof

- Application: Primary, secondary, or final filtration in HVAC, Cleanroom, Painting Booth

- Certifications: ISO 16890, CE, RoHS, UL 900

- Lead Time: 7-14 working days for standard, 15-25 days for custom formats

Specification Comparison Table & Data Visualization

| Property | Plastic Frame Air Filter Media | Metal/Aluminum Frame Media | Pleated Cardboard Panel Media |

|---|---|---|---|

| Frame Material | ABS/HDPE Plastic, Seamless | Galvanized Aluminum, Metal | Waterproof Cardboard |

| Media | Non woven air filter media | Glassfiber, Mixed Fiber | Non woven, Paper |

| Filtration Class | MERV 8-15 / ISO ePM1, ePM2.5, ePM10 | MERV 7-13 | MERV 6-10 |

| Corrosion Resistance | Excellent | Good | Poor |

| Service Life | 12-36 months | 10-24 months | 3-8 months |

| Customization | Full (size, class, logo) | Size only | Limited |

Advantages & Custom Solutions for Industrial Applications

Non woven air filter media delivers exceptional performance in challenging environments found in petrochemical, metallurgy, pharmaceutical, semiconductor, and industrial HVAC sectors:

- Low Energy Consumption: Lower initial resistance (NAFA guidelines).

- Anti-corrosive & Antimicrobial: Resistant to acids, alkalis, and bacteria—ideal for food plants and waterworks.

- Customization: Tailored filtration class, exotic sizes, color-coded frames for zoning, printed company logos for large projects.

- Stability Under Harsh Conditions: Withstands humidity, temperature extremes, fluctuating flow rates.

Application Case Study: Cleanroom Panel Air Filter Replacement

- Industry: Pharmaceutical Cleanroom ISO Class 7-8.

- Challenge: High PM2.5 load, chemical off-gas, frequent filter clogging.

- Solution: Upgraded to plastic frame air filter media with needle-punched non-woven, electrostatic charge, high-dust holding layer.

- Performance: PM2.5 removal improved from 91% to 97% (ISO 16890), filter change interval extended from 4 to 14 months, and annual maintenance costs were reduced by 32%.

- Feedback: “Stable, efficient, easy to replace. Achieved regulatory certification with fewer downtimes.” — Facility Engineer

Competitive Manufacturer Comparison

| Manufacturer | Location | Key Product | Certifications | Lead Time | Custom Capability | Warranty |

|---|---|---|---|---|---|---|

| Anya Filter Media | China | Plastic Frame Air Filter Media | ISO 16890, CE, RoHS, UL 900 | 7-14 Days | Full (OEM/ODM) | 24 months |

| AAF Flanders | USA | PerfectPleat Panel | ISO, MERV, UL | 10-18 Days | Partial | 12 months |

| Freudenberg | Germany | Viledon Nonwoven Media | ISO 16890, EN 779 | 12-21 Days | Partial | 12 months |

Customization Process & Delivery

- Technical consultation: application analysis, parameter proposal, site audit.

- Material/structure selection: custom non woven fabric air filter, frame, and media processing.

- Prototype sample production; ISO/ANSI standard lab testing for pressure drop, efficiency, flammability, and lifetime.

- Order confirmation and contract; formal batch production with full QC process.

- Global delivery support (by sea, air, express); standard lead times: 7-20 days depending on volume.

Professional FAQ: Non Woven Air Filter Media

Summary & References

Non woven air filter media, especially when engineered in advanced formats like plastic frame air filter media, represents the forefront of high-performance, energy-saving, and sustainable air filtration solutions.

Rigorous adherence to ISO, EN, UL, and application-specific standards, plus strong evidence from industry case studies, ensure these filter systems remain trusted in critical air handling units globally.

For more technical discussions, see leading industry publications:

- “Performance Evaluation of Nonwoven Filter Media for HVAC,” in ResearchGate Journal

- NAFA Air Filter Guidelines: nafahq.org/publications/nafa-guidelines/

- “Air Filter Media Market Analysis 2024,” grandviewresearch.com

- “Filtration Testing Standards” ISO 16890:2016

- HVAC-Talk Air Filter Forum hvac-talk.com

Post time: Jul-29-2025