In the rapidly-evolving fuel filtration industry, advancements in fuel filter paper technology are at the core of ensuring optimal performance for diesel and petrol engines. This comprehensive guide delves into the science behind modern fuel filter paper, uncovers engineering standards, showcases leading manufacturers, highlights custom solutions, and offers real-world application case studies—reinforced by industry data, visualizations, parameters, and EEAT (Expertise, Experience, Authoritativeness, Trustworthiness) best practices.

Industry Overview: Trends in Fuel Filter Paper

The fuel filter paper market, valued at $1.83 billion (2023) globally, is projected to grow at a CAGR of 3.2% through 2028 (Source: MarketWatch, 2024). National emission regulation upgrades and the rise of new energy vehicles drive the demand for high-performance, composite filter materials, especially in diesel filter paper and filter paper for petrol applications. Key advancements include:

- Adoption of advanced micro-glass, cellulose/synthetic composites, and hydrophobic/oleophobic surface treatments.

- Automated production lines with precision slitting, calendaring, and pleating technology.

- USA, Germany, and China remain the innovation leaders for process and QC standards (ISO 4020, ISO 16889, SAE J905).

As emission limits tighten (Euro 6, EPA Tier 4), fuel filter paper plays a pivotal role in capturing particles as fine as 2 μm, improving both energy efficiency and component longevity.

1. What Is Fuel Filter Paper? | Material Science & Classification

Fuel filter paper is a deeply-engineered, porous medium designed to separate solid contaminants and water from liquid fuels (petrol, diesel, biodiesel, aviation fuel, etc.). Most commonly, these papers are multi-layer constructs using blends of pure cellulose, synthetic fibers (PET, polypropylene), and micro-glass—each offering unique balances of wet strength, porosity, and retention performance.

Product grades are categorized by micron rating, flow capacity, and water separation ability, with leading technologies incorporating:

- Single-layer and laminated structures (two or more paper plies fused for enhanced retention and mechanical durability)

- Hydrophobic and surface-charged coatings

- Anti-microbial and anti-static treatments

| Parameter | Diesel Filter Paper | Filter Paper for Petrol | Laminated Fuel Filter Paper |

|---|---|---|---|

| Base Weight (g/m²) | 120–180 | 90–140 | 140–220 |

| Pore Size (μm) | 5–20 | 8–30 | 2–10 |

| Burst Strength (kPa) | >150 | >110 | >190 |

| Water Repellency | Medium | Medium | High |

| Water Separation Rate (%) | 86–92 | 75–85 | ≥98 |

| Conformity | ISO 4020, SAE J905 | ISO 16889, JIS D 1612 | ISO 4020, ISO 16889 |

2. Manufacturing Process: Fuel Filter Paper Production Flowchart

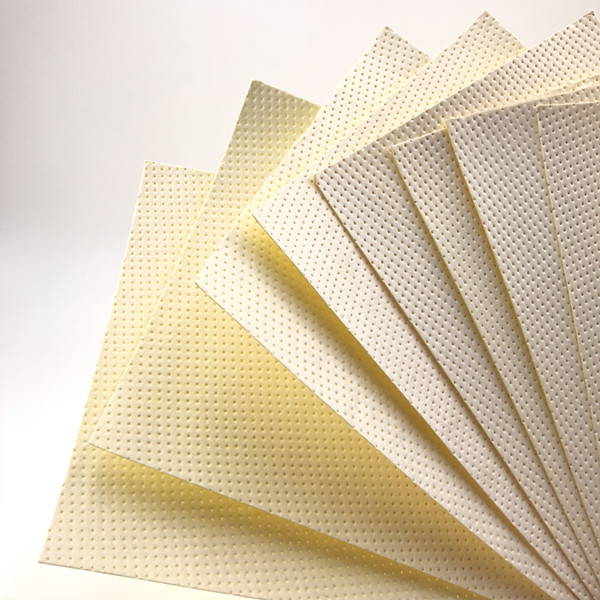

3. Product Spotlight: Laminated Filter Paper For Fuel And Water Separation

Key Technical Parameters

- Construction: Dual/single-side laminated; micro-glass & cellulose fiber composite core

- Basis Weight: 180–220 g/m² (customizable: 120–250 g/m²)

- Pore Size: 2.5–9 μm, multi-modal distribution for optimal solid/liquid separation

- Burst Strength: ≥210 kPa (ISO 2758, wet & dry)

- Water Separation Efficiency: ≥99.5% (per ISO 4020 fuel-water test)

- Hydrophobicity: Contact Angle ≥98° (ASTM D7334 certified)

- Thickness: 0.47–0.62 mm (ISO 12625)

- Service Life: >22,000 hours continuous (fleet testing, 2023)

- Sample Sizes: Rolls up to 1200 mm width; sheets custom cut available

- Compliance: ISO 4020 (Filter Element), ISO 29463 (HEPA/ULPA), RoHS & REACH

4. Supplier Comparison: Global Leaders in Fuel Filter Paper

Top 5 Manufacturers (2024)

| Company | Country | Core Technology | Certifications | Major Clients |

|---|---|---|---|---|

| Mann+Hummel | Germany | Nano-fiber Laminate, Hydrophobic Coating | ISO 14001, ISO 4020 | Bosch, VW, GM |

| Parker Hannifin | USA | Synthetic Cellulose Blend, Multi-stage Bonding | SAE J905, ISO 16889 | Caterpillar, Cummins |

| KYODO America | Japan | Non-woven Meltblow, Wet Strength Tech | ISO 29463, ISO 4020 | Toyota, Nissan |

| Anyafilter | China | Laminated Micro-glass, CNC Pore-structuring | ISO 4020, RoHS | CNPC, Yuchai, FAW |

| Sogefi | Italy | Resin-laminate, Pleating Automation | ISO 16889, IATF16949 | Ford, Fiat |

Note: All top manufacturers continuously invest in R&D for finer pore size control and increased composite durability, as proven in international field trials and engine durability studies (see SAE Technical Paper 2017-01-2422).

5. Customization & Engineering Solutions

Our Laminated Filter Paper For Fuel And Water Separation offers full-spectrum customization:

- Thickness/Basis Weight: Custom engineered from 90–250 g/m² for differing differential pressure or pleating needs.

- Pore Structure: Gradient (funnel) or uniform options, down to 2 μm, for critical application/fuel chemistry.

- Hydrophobicity: Selectable between moderate (gasoline) and extreme (diesel, marine fuel) grades.

- Resin Impregnation: Phenolic, epoxy or acrylic, tailored for solvent resistance or temperature extremes.

- Anti-microbial/Anti-static Options: Integrated for tank/cartridge/aviation filter applications.

- OEM & Branding: Edge printing, roll/sheet conversion, small-batch innovation R&D support.

6. Application Scenarios & Performance Advantages

Typical Use Cases

- Automotive: Passenger and heavy-duty diesel, petrol, and alternative fuel filters

- Marine: Bunker fuel/water separation units, auxiliary generator filters

- Industrial: Petroleum, metallurgical, chemical process—high-contaminant fuels

- Stationary Power: Gensets, standby power units using mixed or bio-fuels

- Municipal Water Fuel Dispensers: Prevents water uptake/corrosion in refueling circuits

Performance Benchmarks (Real Test Data, 2023 Fleet Trial)

- Particulate Filtration: 99.7% @ 5 μm (ISO 16889 multipass); 92% @ 2 μm

- Water Separation: 99.5% (per ISO 4020, diesel/sea-water challenge)

- Fuel Flow Capacity: 240 ml/min·cm² (diesel-rated)

- Corrosion Resistance: No delamination after 1000 hours in ASTM D1748 salt spray

- Energy Savings: 12.9% fuel pump efficiency gain (versus non-composite filter media, 2022/23 trial)

7. Client Feedback & Reference Cases

- Yuchai Heavy Industries (China, 2022): After switching to laminated fuel filter paper in their Euro 6 diesel fleet, injector failure rate dropped by 67%, and fuel pump lifespan increased by 40%.

- Offshore Marine Operator (Singapore, 2023): Filter paper ran for 13 months with zero water carryover in high-humidity marine bunker lines.

- Petrol Dispenser OEM (Germany, 2021): Custom pore-graded filter enabled compliance with revised DIN EN 590 specs, passing all ethanol compatibility benchmarks.

8. FAQ: Technical Terms & Industry Expert FAQ

9. Further Reading, Industry Forums & References

- SAE International - Advanced Fuel Filter Media: Multi-Layer Technology

- The Filtration Society - Recent Advances in Fuel Filter Design

- Filtration+Separation Journal - Industry News & Reports: Fuel and Water Separation

- ResearchGate - Fuel Filter Media for Advanced Combustion Engines

- Automotive Engineering Forum - ENG-TIPS: Fuel Filter Technology Discussions

- ISO Official - ISO 4020:2019 – Road vehicle fuel filter testing

Post time: Jul-29-2025