The Evolution of Air Filtration: Why Fiberglass Media Leads

In industrial and commercial settings, air quality is not merely a matter of comfort but a critical factor influencing operational efficiency, equipment longevity, and public health. As industries strive for higher standards of purity and reduced environmental impact, the demand for advanced filtration solutions intensifies. Among the myriad of filter media available, a fiberglass filter media air filter stands out as a superior choice, especially for applications requiring high efficiency, low resistance, and robust performance in challenging environments. This comprehensive guide delves into the technical intricacies, manufacturing excellence, diverse applications, and inherent advantages of modern fiberglass filter solutions, providing insights for B2B decision-makers seeking optimal air purification. The global air filter market is projected to reach USD 22.8 billion by 2028, with fiberglass media components playing a significant role due to their cost-effectiveness and performance attributes in HVAC and industrial process filtration. This growth underscores the increasing awareness and stringent regulations regarding airborne contaminants.

Unpacking the Manufacturing Excellence of Composite Fiberglass Filter Media

The production of Composite Fiberglass Filter Media, like that offered by Anyafiltermedia, involves a sophisticated multi-stage process designed to ensure superior filtration performance and durability. Unlike traditional textile processes, the manufacturing of fiberglass filter material for air filtration is a specialized non-woven technology. It begins with the precise formulation of high-quality glass fibers, primarily borosilicate glass, known for its excellent chemical resistance and high-temperature tolerance. These fibers undergo a meticulous sizing process to ensure uniform diameter and distribution. The primary manufacturing stages include wet-laid formation, where a slurry of glass fibers and binding agents is uniformly deposited onto a moving screen, followed by dewatering and drying. This forms a continuous, homogeneous web. Subsequently, the dried web undergoes a controlled thermal bonding process, which cures the binding agents, imparting structural integrity and desired stiffness to the media. For composite media, multiple layers of different fiber types or densities might be laminated together using advanced calendering techniques, which compress the layers and further enhance mechanical strength and filtration efficiency. Each step is rigorously controlled to meet stringent quality parameters, ensuring the final fiberglass filter cloth delivers consistent and reliable performance.

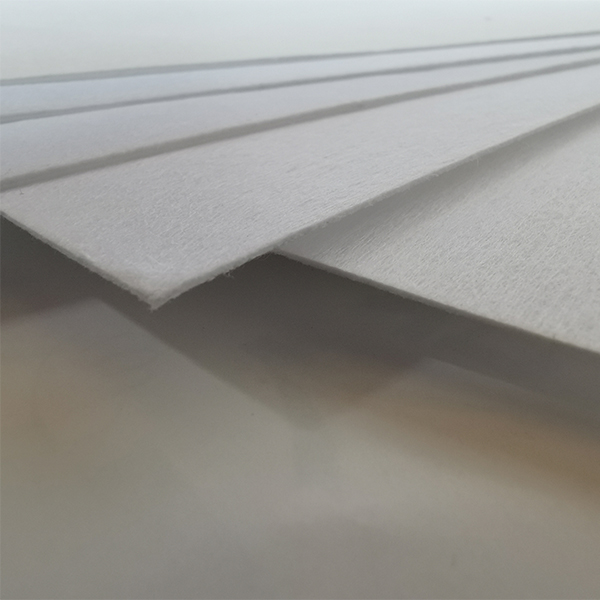

A close-up view of the intricate structure of Composite Fiberglass Filter Media.

Quality control is paramount throughout the entire manufacturing flow. This includes continuous monitoring of fiber dispersion, web uniformity, media thickness, weight, and air permeability. Post-production, each batch of fiberglass filter material undergoes rigorous testing in accordance with international standards such as ISO 16890 and EN 779 for particle filtration efficiency (PFE), initial pressure drop, and dust holding capacity. The precision in manufacturing ensures that the media can effectively capture sub-micron particles, including dust, pollen, mold spores, and even certain viruses and bacteria, depending on the MERV (Minimum Efficiency Reporting Value) rating. Our Composite Fiberglass Filter Media is designed for optimal lifespan, significantly reducing maintenance cycles in high-volume applications, often exceeding 12-18 months in typical industrial HVAC systems, depending on the specific dust load and operational conditions. This extended lifespan translates directly into cost savings and reduced operational downtime for our clients.

Technical Specifications and Performance Metrics

Understanding the technical parameters of a fiberglass filter media air filter is crucial for selecting the right solution for specific industrial needs. Our Composite Fiberglass Filter Media offers a range of specifications tailored for diverse applications, from general ventilation to specialized cleanroom environments. Key performance indicators include filtration efficiency, initial pressure drop, dust holding capacity, and flame retardancy. These metrics are not just numbers; they directly translate to operational cost savings (through reduced energy consumption), enhanced indoor air quality, and compliance with stringent environmental regulations. The design of fiberglass filter cloth allows for a high specific surface area, maximizing particle capture while minimizing airflow resistance, a critical balance for energy-efficient systems.

These detailed specifications highlight Anyafiltermedia's commitment to delivering products that not only meet but often exceed industry benchmarks. The superior dust holding capacity, for instance, translates directly into reduced filter change-out frequencies, significantly cutting down on maintenance labor and material costs for our clients. Furthermore, the inherent fire retardancy of fiberglass filter material adds an essential safety layer, especially in industrial processes where potential fire hazards exist, ensuring compliance with strict safety regulations like NFPA standards.

Diverse Application Scenarios and Core Advantages

The versatility of a fiberglass filter media air filter makes it indispensable across a wide array of industrial and commercial sectors. Its robust performance characteristics are particularly beneficial in environments demanding high-efficiency particulate air (HEPA) or ultra-low particulate air (ULPA) filtration. Key application areas include:

- HVAC Systems: Essential for commercial buildings, hospitals, and data centers, ensuring clean air circulation and protecting expensive HVAC components from particulate buildup.

- Automotive Industry: Used in paint booths and manufacturing facilities to prevent dust contamination and ensure product quality.

- Pharmaceutical and Biotechnology: Critical for cleanroom environments (ISO Class 5-8), preventing cross-contamination and ensuring product purity, where sterile air is paramount.

- Food and Beverage Processing: Maintains hygienic production environments, preventing airborne contaminants from affecting food safety and quality.

- Power Generation: Protects gas turbines and other sensitive equipment from corrosive particles and extends operational life.

- Electronics Manufacturing: Crucial for fabricating sensitive components in dust-free conditions, preventing defects.

- Petrochemical and Chemical Plants: Effective in filtering corrosive fumes and particulate matter, thanks to the chemical inertness of fiberglass filter material.

Applications of fiberglass filter media in industrial air purification systems.

The core advantages of our Composite Fiberglass Filter Media lie in its superior filtration efficiency, low energy consumption due to minimal pressure drop, and exceptional durability. Compared to synthetic media, fiberglass offers a higher operating temperature range, crucial for industrial exhaust systems. Its non-hygroscopic nature prevents moisture absorption, which could otherwise lead to microbial growth or reduced performance. Furthermore, the inherent corrosion resistance of the fiberglass filter cloth ensures reliable operation in chemically aggressive environments, extending the filter's service life and reducing the frequency of costly replacements. Our products contribute significantly to energy savings, with studies showing up to a 15% reduction in fan energy consumption compared to filters with higher initial pressure drops. This makes them a cost-effective and environmentally friendly choice for long-term operational sustainability.

Customization Capabilities and Solution Design

Recognizing that every industrial application has unique filtration requirements, Anyafiltermedia excels in providing highly customizable Composite Fiberglass Filter Media solutions. Our technical team works closely with clients to understand their specific operational parameters, including airflow rates, contaminant types and concentrations, temperature and humidity conditions, and desired filtration efficiency levels. This collaborative approach ensures that the selected fiberglass filter material is perfectly aligned with the client's needs, optimizing performance and cost-effectiveness. Customization options include varying media thickness, fiber blend ratios, basis weight, and the integration of multiple layers for enhanced performance. For instance, for applications requiring very fine particle capture (e.g., ePM1 > 80%), we can engineer media with a denser fiber matrix or introduce an additional fine fiber layer. Conversely, for pre-filtration stages, a media designed for higher dust holding capacity might be recommended to extend the life of downstream HEPA filters. We also offer media treated for specific properties, such as enhanced flame retardancy or anti-microbial characteristics. Our engineering prowess ensures that whether it's a standard HVAC requirement or a highly specialized industrial process filter, the final product delivers unparalleled results.

Our team collaborating on custom fiberglass filter media development.

Our design process integrates advanced simulation tools to predict filtration performance under various conditions, minimizing trial and error and accelerating deployment. This commitment to tailor-made solutions has enabled us to serve diverse industries, providing a precise a fiberglass filter media air filter for their unique challenges. From concept to delivery, our team provides comprehensive technical support, ensuring seamless integration and optimal performance. This bespoke approach sets Anyafiltermedia apart, demonstrating our expertise and experience in delivering value-driven filtration solutions that truly meet our clients' operational demands and sustainability goals.

Client Success Stories and Unwavering Commitment to Quality

Anyafiltermedia's success is built on a foundation of trust and consistent delivery of high-performance filtration solutions. Our long-standing relationships with leading industrial players underscore our authoritativeness in the sector. For example, a major petrochemical complex faced persistent issues with premature clogging of their air intake filters due to high concentrations of fine particulate matter and corrosive gases. After implementing our specially engineered Composite Fiberglass Filter Media, designed for enhanced chemical resistance and dust holding capacity, they reported a 30% increase in filter lifespan and a significant reduction in associated maintenance costs, leading to an estimated annual saving of USD 150,000 in filter replacements and labor. Another case involved a European pharmaceutical manufacturer struggling with maintaining ISO Class 7 cleanliness in their production area. By upgrading to our high-efficiency fiberglass filter cloth as part of their final filtration stage, they consistently achieved ISO Class 6 conditions, exceeding their regulatory requirements and ensuring product integrity. These testimonials are a testament to the tangible benefits our a fiberglass filter media air filter provides.

Illustrating the superior dust-holding capacity of our fiberglass filter media.

Our commitment to quality is upheld by stringent internal quality management systems, certified under ISO 9001:2015. Every product batch undergoes rigorous in-house testing and third-party validation to ensure compliance with international standards such as ASHRAE 52.2 and Eurovent 4/10. We offer a comprehensive warranty covering material defects and manufacturing faults, ensuring peace of mind for our clients. Our typical delivery lead times range from 2-4 weeks for standard orders, with expedited options available for urgent requirements, supported by a robust global logistics network. Dedicated customer support is available 24/7 to address any technical queries or logistical concerns, further solidifying our position as a trusted partner in advanced air filtration.

Frequently Asked Questions (FAQ)

Q: What makes Composite Fiberglass Filter Media superior to synthetic alternatives?

A: Composite Fiberglass Filter Media offers superior temperature resistance (up to 280°C), excellent chemical inertness, and a unique fiber structure that allows for higher dust holding capacity with lower initial pressure drop compared to many synthetic alternatives. This results in significant energy savings and extended filter lifespan for a fiberglass filter media air filter. Its non-hygroscopic nature also prevents moisture absorption and potential microbial growth.

Q: How do I determine the right MERV rating for my application?

A: The appropriate MERV rating depends on the specific air quality requirements of your application. For general HVAC, MERV 8-10 may suffice. For cleaner environments like hospitals or sensitive manufacturing, MERV 13-16 is often required. For HEPA applications, MERV 17-20 equivalent filters are needed. Our experts can assist in assessing your needs and recommending the optimal fiberglass filter material solution.

Q: Is fiberglass filter media safe to handle?

A: Modern fiberglass filter cloth is designed with safety in mind. While minor skin irritation can occur from direct contact with loose fibers, our composite media is manufactured to minimize fiber shedding. Standard industrial safety practices, such as wearing gloves and eye protection during installation and removal, are recommended. Our products comply with international health and safety regulations.

Q: What is the typical lead time for a custom order of Composite Fiberglass Filter Media?

A: For customized Composite Fiberglass Filter Media, the lead time typically ranges from 4-6 weeks, depending on the complexity and volume of the order. We maintain transparent communication throughout the production process and offer expedited options for urgent requirements. Our efficient manufacturing and logistics ensure timely delivery worldwide.

References and Further Reading

- ASHRAE Standard 52.2-2017: Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size.

- ISO 16890-1:2016: Air filters for general ventilation — Part 1: Technical specifications, requirements and classification system based on particulate matter (PM).

- Eurovent 4/10: Efficiency Classification of Air Filters for General Ventilation.

- National Fire Protection Association (NFPA) Standards: Guidelines for fire safety in industrial applications.

- Frost & Sullivan: Global Air Filter Market Analysis, 2022.

Post time: Aug-12-2025