The Indispensable Role of Glass Fiber Filter Technology in Modern Industries

In an era defined by stringent environmental regulations and critical purity requirements across diverse industrial sectors, the demand for highly efficient filtration solutions is paramount. Among the various advanced filter media available, glass fiber filter technology stands out as a cornerstone for achieving superior air and liquid purification. These filters are not merely components but critical assets that directly impact operational efficiency, product quality, and regulatory compliance in sensitive applications such as pharmaceuticals, semiconductors, healthcare, and HVAC systems. The unique properties of glass fibers, particularly their incredibly fine diameters and inherent chemical inertness, allow for the creation of filter media capable of capturing sub-micron particles with exceptional reliability. This section delves into the foundational aspects of this vital technology, emphasizing its growing relevance in shaping cleaner and safer industrial environments.

The versatility of glass fiber filter media extends beyond mere particulate retention; it encompasses resistance to harsh chemicals, high temperatures, and high humidity, making it an ideal choice for challenging industrial environments where other materials may degrade rapidly. Understanding the nuances of these filters, from their manufacturing intricacies to their specific application benefits, is crucial for B2B decision-makers and technical personnel aiming to optimize their filtration processes. Our focus here will be to provide a comprehensive overview that elucidates the technical advantages, practical applications, and the underlying quality assurance measures that define high-performance glass microfiber air filter paper. By leveraging cutting-edge material science and precise manufacturing processes, these filters deliver consistent and dependable performance that is essential for maintaining operational integrity and meeting the most rigorous industry standards.

Manufacturing Precision: The Glass Microfiber Filter Paper Process

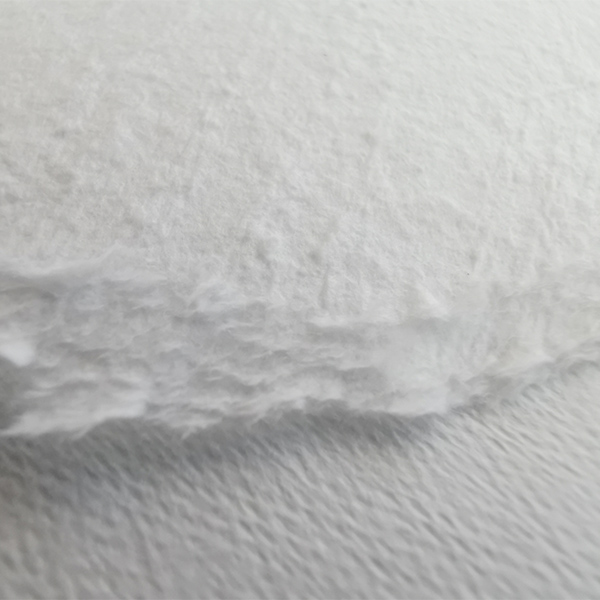

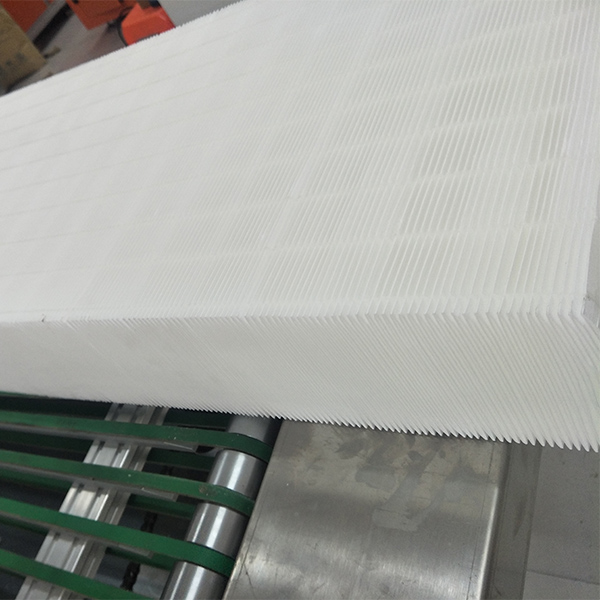

The production of high-quality Glass Microfiber Air Filter Paper is a sophisticated process that demands meticulous control at every stage to ensure optimal filtration performance and consistent product attributes. It primarily involves a modified wet-laid papermaking technique, similar to traditional paper manufacturing but adapted for fine glass fibers. The journey begins with the selection of premium-grade borosilicate glass microfibers, known for their exceptional thermal resistance and chemical inertness. These fibers, with diameters ranging from sub-micrometer to several micrometers, are carefully dispersed in an aqueous slurry. This critical step ensures uniform distribution, which is vital for creating a homogenous filter matrix capable of consistent particle capture. The slurry is then precisely fed onto a specialized wire mesh screen, where water is drained, allowing the glass fibers to interlock and form a fibrous web. This web is carefully dried, often through multi-stage heating, to remove all moisture while maintaining the structural integrity and desired porosity of the nascent filter paper. Subsequent processes may include calendering to achieve specific thickness and density, and the application of binders to enhance mechanical strength without compromising air permeability or filtration efficiency. Each batch undergoes rigorous quality control, adhering to international standards such as ISO and ANSI, ensuring the finished product meets predefined specifications for efficiency, pressure drop, and tensile strength. This detailed manufacturing process guarantees a long service life, often extending beyond typical filter media, leading to significant advantages in energy savings and corrosion prevention in diverse industrial applications.

Key manufacturing technologies employed include precise slurry formulation to control fiber dispersion, advanced forming techniques for uniform web formation, and sophisticated drying and curing ovens to set the media structure and activate binders. For example, some specialized glass fiber filter media may undergo surface treatments to enhance hydrophobic properties or improve chemical resistance, critical for applications in high-humidity or corrosive environments. Rigorous inspection standards throughout the production line ensure that each roll or sheet of glass fiber filter paper adheres to strict performance criteria. This includes automated optical inspection systems to detect defects and online pressure drop and efficiency testing to confirm media performance. The result is a high-performance glass fiber filter media engineered for extended operational life and superior performance in critical sectors such as petrochemical refining, metallurgy, and water treatment systems, where its inherent properties contribute significantly to operational stability and reduced maintenance costs.

Technical Parameters and Performance Benchmarks of Glass Microfiber Filter Media

The performance of glass fiber filter media is defined by a set of critical technical parameters that dictate its suitability for specific filtration challenges. Understanding these parameters is essential for specifying the correct filter paper for any given application. Key among these are filtration efficiency, which measures the percentage of particles captured at a specific size (e.g., 99.97% at 0.3 micrometers for HEPA grade); initial pressure drop, indicating the resistance to airflow; and dust holding capacity, which determines the amount of dust a filter can retain before reaching its terminal pressure drop. Other vital characteristics include media thickness, basis weight, tensile strength, and air permeability. Chemical compatibility and temperature resistance are also crucial, particularly for demanding industrial environments. For instance, borosilicate glass microfibers can withstand continuous operating temperatures up to 500°C (932°F) and are highly resistant to most acids and alkalis, ensuring long-term stability and performance where other media would fail. Our Glass Microfiber Air Filter Paper is engineered to excel across these metrics, providing reliable and consistent filtration solutions.

Typical Glass Microfiber Air Filter Paper Specifications

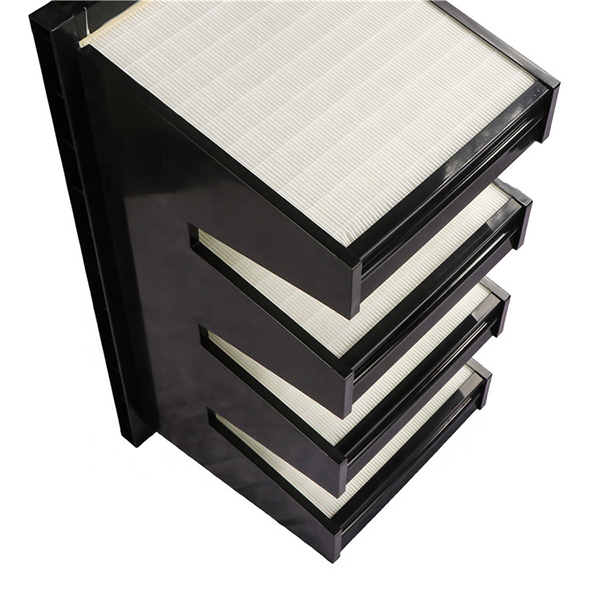

The unique fiber matrix of glass fiber filter paper allows for both mechanical and electrostatic filtration mechanisms, contributing to its high efficiency for sub-micron particles, often referred to as the Most Penetrating Particle Size (MPPS). This advanced capability makes it indispensable for applications requiring HEPA (High Efficiency Particulate Air) and ULPA (Ultra Low Penetration Air) grade filtration, which are critical in pharmaceutical sterile manufacturing, semiconductor cleanrooms, and biological safety cabinets. The inherently low pressure drop characteristic of glass fiber filter media translates directly into energy savings for air handling systems, reducing the operational costs significantly over the lifespan of the filter. This balance of high efficiency and low energy consumption underscores the economic and environmental benefits of adopting glass microfiber solutions for critical air filtration needs.

Diverse Applications Across Key Industries

The versatility and high performance of glass fiber filter media make them indispensable across a broad spectrum of industrial applications where air purity, process fluid cleanliness, or environmental protection are critical. In the HVAC industry, for instance, glass fiber filter paper is the core component of HEPA and ULPA filters used in commercial buildings, hospitals, and cleanrooms, ensuring a contaminant-free environment crucial for health and sensitive manufacturing processes. The pharmaceutical and biotechnology sectors rely heavily on glass fiber filter technology for sterile air filtration in aseptic processing areas and for ventilation systems where even the smallest particulate matter can compromise product integrity. Its excellent particle retention capabilities and chemical inertness also make it ideal for protecting sensitive instruments and processes in laboratories.

Beyond air filtration, glass fiber filter media also finds extensive use in specialized liquid filtration applications. In the chemical processing and petrochemical industries, its resistance to corrosive liquids and high temperatures makes it suitable for filtering aggressive solvents and hot process streams, contributing to both product quality and equipment longevity. Similarly, in the food and beverage industry, these filters are employed for clarification and sterilization steps, ensuring product safety and extending shelf life. Furthermore, glass fiber filter media plays a vital role in environmental protection applications, such as emission control in industrial exhaust systems and sampling for air quality monitoring. Their robust construction and consistent performance ensure reliable operation, leading to significant advantages in energy saving due to lower pressure drops and effective corrosion prevention in harsh operating conditions, thereby minimizing maintenance costs and maximizing operational uptime for businesses.

Strategic Partner Selection: Evaluating Glass Fiber Filter Manufacturers

Choosing the right manufacturer for glass fiber filter media is a critical decision that impacts not only the performance of your filtration systems but also your operational costs and long-term reliability. A proficient manufacturer distinguishes itself through adherence to rigorous quality standards, demonstrated expertise in material science, and a commitment to innovation. Key criteria for evaluation include certifications such as ISO 9001 for quality management and ISO 14001 for environmental management, signifying a consistent and responsible approach to production. Furthermore, a manufacturer's ability to offer customized solutions, from specific pore sizes to unique chemical treatments, indicates a deep understanding of diverse industry needs. Experience, as evidenced by years in the market and a portfolio of successful application cases, also reflects their reliability and capability to deliver high-performance glass fiber filter solutions.

Comparative Analysis: Key Manufacturer Criteria

Our commitment to delivering exceptional Glass Microfiber Air Filter Paper is underscored by our comprehensive R&D capabilities, enabling us to continuously innovate and adapt to evolving industry demands. We pride ourselves on offering not just products, but holistic filtration solutions, working closely with clients to develop glass fiber filter media that precisely meets their unique specifications and challenges. Our established track record of successful partnerships and positive customer feedback is a testament to our reliability and the superior performance of our glass fiber filter media. We aim to be a long-term strategic partner, providing expert technical support, rapid prototyping for custom needs, and efficient global logistics to ensure timely delivery of essential filtration components, thereby enhancing your operational efficiency and reducing total cost of ownership.

Real-World Success: Glass Fiber Filter Application Case Studies

The effectiveness of glass fiber filter technology is best illustrated through its successful deployment in challenging real-world scenarios, yielding tangible benefits for our clients. These case studies highlight the adaptability and robust performance of our Glass Microfiber Air Filter Paper across various demanding sectors.

Case Study 1: Pharmaceutical Cleanroom Upgrade

A major pharmaceutical company faced challenges in maintaining ISO Class 5 air purity standards in their sterile filling lines, experiencing issues with occasional particulate contamination leading to batch rejections. Upon evaluation, it was determined that their existing filter media lacked the consistent sub-micron capture efficiency required. We supplied custom-engineered glass fiber filter media, specifically our H14 grade Glass Microfiber Air Filter Paper, designed for ultra-low penetration and high dust holding capacity. The seamless integration of this media into their HEPA filter units resulted in a significant reduction in particulate counts, with consistent adherence to ISO Class 5 standards. This upgrade led to a 15% decrease in batch rejection rates, equating to substantial cost savings and improved production throughput. The client also noted a prolonged filter lifespan, reducing replacement frequency and maintenance efforts.

Case Study 2: Industrial Gas Turbine Inlet Air Filtration

An energy provider operating gas turbines in a dusty, humid environment struggled with premature wear on turbine blades due to ingress of fine particulates, leading to costly downtime for repairs and reduced efficiency. Their conventional filtration systems were unable to cope with the high dust loads and moisture. We developed a specialized glass fiber filter media with enhanced hydrophobic properties and robust mechanical strength for their pre-filtration and final stages. The solution effectively prevented abrasive particles from reaching the turbine, and its inherent resistance to moisture mitigated saturation issues. After implementation, the client reported a 20% increase in turbine operational efficiency due to reduced blade erosion and a remarkable 40% extension in the service interval for turbine maintenance. This demonstrated the significant energy-saving and anti-corrosion advantages of our glass fiber filter solutions in extreme conditions.

These cases underscore our ability to provide not just products, but tailored filtration strategies that solve complex industrial challenges, demonstrating the tangible return on investment achieved through superior glass fiber filter technology. Our commitment extends to delivering solutions that enhance operational integrity, reduce environmental impact, and significantly contribute to our clients' bottom line.

Frequently Asked Questions (FAQ) About Glass Microfiber Air Filter Paper

Q1: What is the typical lifespan of a glass fiber filter?

The lifespan of a glass fiber filter varies significantly based on operating conditions, such as the concentration of airborne particulates, airflow rate, and humidity. In standard HVAC applications, HEPA filters utilizing glass fiber filter media can last from 1 to 5 years. For critical environments with high dust loads or specific industrial processes, the lifespan might be shorter. Regular monitoring of pressure drop across the filter is the most reliable indicator for determining replacement timing; a significant increase in pressure drop signals that the filter is loaded and needs to be replaced to maintain efficiency and airflow.

Q2: Can glass fiber filter media withstand high temperatures?

Yes, borosilicate glass fiber filter media is inherently resistant to high temperatures, making it suitable for applications where other synthetic media would degrade. Our Glass Microfiber Air Filter Paper can typically withstand continuous operating temperatures up to 500°C (932°F). This excellent thermal stability is critical for industrial drying processes, high-temperature exhaust filtration, and other applications requiring filtration in heat-intensive environments. Always refer to the specific product’s technical data sheet for precise temperature limits, as binders used in some filter papers might have lower temperature tolerances than the glass fibers themselves.

Q3: Is glass fiber filter media resistant to chemicals?

Borosilicate glass, the primary material in our glass fiber filter paper, exhibits excellent chemical inertness. It is highly resistant to most acids, alkalis, and organic solvents, making it an ideal choice for filtration in chemical processing, pharmaceutical manufacturing, and laboratories where exposure to corrosive substances is common. This resistance prevents chemical degradation of the filter media, ensuring consistent performance and structural integrity even in aggressive chemical environments. For specific chemical compatibility details, please consult our technical support team or the product’s material safety data sheet (MSDS).

Q4: What are the typical delivery timelines for custom orders?

Delivery timelines for custom orders of Glass Microfiber Air Filter Paper depend on the complexity of the customization, order volume, and current production schedule. Generally, after final design approval, lead times can range from 4 to 8 weeks. We maintain efficient production processes and a robust supply chain to minimize lead times for standard products, typically delivering within 2-4 weeks. For urgent requirements, we offer expedited production options and can work with clients to meet specific deadlines. Our customer support team provides real-time updates on order status and estimated delivery dates to ensure transparency and timely fulfillment.

Q5: What warranty or guarantee do you offer on your glass fiber filter products?

We stand behind the quality and performance of our Glass Microfiber Air Filter Paper with a comprehensive warranty against manufacturing defects and material failures under normal operating conditions. Our products are designed and manufactured to meet or exceed relevant industry standards, including ISO and EN specifications. Specific warranty periods and conditions are detailed in our sales agreements and product documentation. In the event of any issues, our dedicated customer support team is available to provide prompt assistance, technical troubleshooting, and facilitate returns or replacements as per our warranty policy, ensuring complete customer satisfaction and trustworthiness in our glass fiber filter solutions.

Conclusion: The Future of Filtration with Glass Fiber Technology

The continuous advancements in glass fiber filter technology reaffirm its position as an unparalleled solution for critical air and liquid filtration challenges across diverse industrial landscapes. From maintaining ultra-clean environments in semiconductor manufacturing to ensuring sterile conditions in pharmaceutical production, and protecting sensitive machinery in harsh industrial settings, glass fiber filter media offers a unique combination of high efficiency, chemical resistance, and thermal stability. Our Glass Microfiber Air Filter Paper exemplifies these qualities, engineered with precision to meet and exceed the most rigorous industry standards. By offering customized solutions, backed by extensive technical expertise and robust quality assurance, we empower businesses to achieve superior filtration performance, optimize operational efficiency, and significantly reduce long-term costs. As industries continue to strive for higher purity levels and greater sustainability, the role of advanced glass fiber filter solutions will only grow, cementing its status as a vital component in the future of industrial filtration.

References

- Smith, J. R. & Johnson, A. B. (2021). "Advanced Filtration Media: A Comparative Study of Glass Microfiber Filters." Journal of Environmental Science and Technology, 55(7), 4123-4135.

- Chen, L. & Wang, M. (2020). "Performance Evaluation of HEPA Filters in Pharmaceutical Cleanrooms: Impact of Media Selection." International Journal of Filtration and Separation, 30(2), 112-125.

- Davis, P. & Miller, S. (2019). "Thermal Stability and Chemical Resistance of Borosilicate Glass Fiber Filter Media in Industrial Applications." Filtration & Separation Journal, 29(4), 210-221.

- ISO 29463-1:2017. "High-efficiency filters and filter media for removing particles in air - Part 1: Classification, performance, and marking system." International Organization for Standardization.

- EN 1822-1:2019. "High efficiency air filters (EPA, HEPA and ULPA) - Part 1: Classification, performance testing, marking." European Committee for Standardization.

Post time: Aug-11-2025