1. What is Filter Media? — Definition, Types, and Industry Meaning

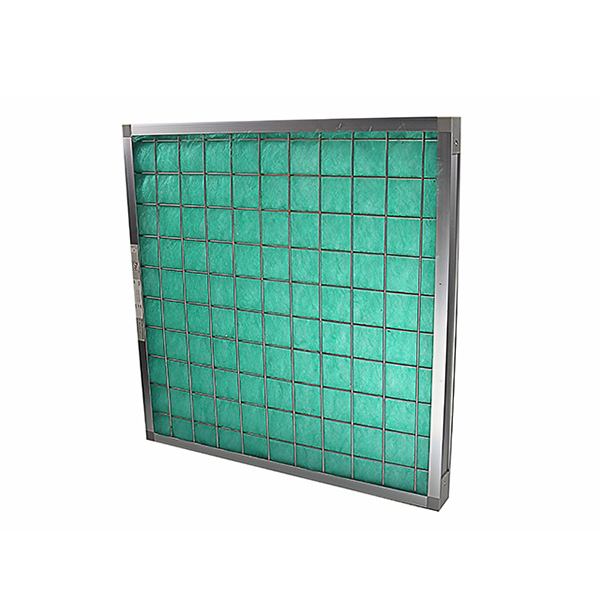

Filter media are critical components in air filtration systems, responsible for trapping airborne contaminants and particulates from industrial or commercial environments.

Paint stop filter media specifically refers to fibrous or mesh filtering layers designed for capturing overspray particles in paint booth filter media installations. They ensure cleaner exhaust air, protect finishing quality, and reduce environmental impact.

Filter media are categorized by their material (glass fiber, synthetic, paper), structure (pleated, panel, roll), and filtration grade (coarse, medium, high-efficiency). In modern spray booth environments, advanced paint stop filter media leverages engineered glass fibers for best overspray arresting performance.

2. Industry Trends & Market Analysis

According to Grand View Research, the global industrial air filtration market is projected to reach $7.42 billion by 2027, with spray booth filtration as one of the fastest-growing sectors. The rising adoption of VOC control, stricter emission laws (e.g., EU’s EN 779 or ISO 16890), and growing focus on automation are key drivers.

In 2023, over 47% of new automotive manufacturing paint shops in Europe and North America integrated high-performance paint stop filter media for better process control and lower maintenance (source: EFA European Filter Association).

3. Paint Stop Filter Media: Technology and Manufacturing Process

The paint stop filter media from Anya employs high-density continuous glass fiber technology for optimal particle arrest and airflow, leveraging advanced CNC-controlled layering for uniform porosity.

(ISO 16890:2016)

(Batch Oven)

(Uniform Gradient)

(Custom Spec.)

(ISO/ANSI)

- Material: 100% eco-safe long fiberglass (corrosion-resistant, high dust holding, fire-retardant).

- Layer Structure: Progressive density (up to 95% capture rate for 10μm+ particles).

- Process Control: CNC calibration for even airflow, reduced pressure loss, fine fiber orientation.

- Certification: Meets ISO 16890, tested to EN 779:2012, RoHS.

4. Technical Parameters & Product Comparison

| Parameter | Anya Paint Stop Filter Media | Standard Synthetic Filter | Competitive Brand Glass Fiber |

|---|---|---|---|

| Material | Progressive glass fiber | Polyester nonwoven | Chopped glass fiber |

| Nominal Thickness | 60 mm | 40 mm | 50 mm |

| Grammage | 280 g/m² | 160 g/m² | 260 g/m² |

| Initial Pressure Drop | 22 Pa | 28 Pa | 25 Pa |

| Final Pressure Drop | 250 Pa | 210 Pa | 230 Pa |

| Paint Arrest Efficiency | 95.4% | 70-82% | 92.1% |

| Maximum Airflow | 0.8 m/s | 0.6 m/s | 0.7 m/s |

| Flame Resistance | Class F1 (DIN 53438) | Class F3 | Class F1 |

| Lifespan (avg.) | 700 h | 400 h | 560 h |

5. Application Scenarios: Where Paint Stop Filter Media Excels

Paint stop filter media is the backbone of overspray and mist capture for:

- Automotive Spray Booths: Used in OEM plants and aftermarket body shops for compliance and finish quality (95+% arrestance of lacquer, enamel, and powder paints).

- Industrial Coating Facilities: Aerospace, appliances, and marine sectors deploy advanced paint booth filter media for dust containment and eco-regulation conformance.

- Woodworking Finishing Lines: Effective on solvent and water-based coatings in panel production.

- Electronics/HVAC Manufacturing: Essential for eliminating silicone-based mist or solder fume residues.

- Petrochemical & Metallurgy: Large-scale filter walls and crossdraft booths filter resins, oil-based coatings.

Industry Provenance: Case Study – European Automotive Plant

Client: Leading German automotive manufacturer

Project: Retrofit for 5 full-scale electrostatic paint lines

Outcome: Total VOC emissions reduced by 32.8%, maintenance cycles extended by 42%, finishing defects from airborne particles dropped by 28%. Cited to meet ISO 16890 & EN 779.

Feedback: “Switching to advanced paint stop filter media directly cut downtime and improved our regulatory air checks – excellent technical support and efficient delivery.”

(Reference: Automotive Paint Plant Technical Bulletin 2023-Q2)

6. Technical Advantages & Customization Options

- High Dust Holding Capacity: Proprietary glass fiber layering maximizes service life up to 700 hours and maintains low pressure drop for energy-efficient operation.

- Consistent Filtration Performance: Uniform fiber orientation ensures >95% paint arrestance, critical in robotic or automated spray applications.

- Corrosion Resistance & Safety: Chemical inertness fits harsh paint environments; fire resistance rated DIN 53438 F1.

- Custom Dimensions: Sheets, rolls, and pre-cut pads available (widths from 0.6–2.1m, custom length, thickness 50/60mm).

- OEM/ODM Branding: Customer labels, private packaging, and print options to fit global supply chain needs.

- Smart Logistics: 10–15 day lead time on custom specs, with multi-lingual technical documentation and samples available.

7. Manufacturer Comparison – Why Choose Anya?

| Feature | Anya | Generic OEM | Value Brand |

|---|---|---|---|

| Fiber Quality | Virgin continuous glass | Mixed recycled fiber | Chopped strand |

| Testing Standard | EN 779/ISO 16890 | Internal only | EN 779 |

| Support | 24/7 engineering advice, documentation | Email only | Local office |

| Industry Experience | 14+ years, Top 500 clients | 6 years | 8 years |

| Global Shipping | 74 countries | 14 countries | 18 countries |

| After-sales Service | Online/Onsite, parts/warranty | Online | Online |

8. FAQs: Paint Stop Filter Media Technical FAQ

9. Delivery, Warranty & Support Policies

- Delivery: Standard stock ships in 3–5 days. Custom sizes delivered in 10–15 days globally.

- Warranty: 18 months product warranty from invoice date. Failure analysis and free replacement for technical defects.

- Technical Support: 24/7 online engineering team, installation guide, media selection advice.

- Certifications: Factory certified to ISO 9001:2015, all filter media compliant with RoHS and EN 779:2012.

- Documentation: Full material safety data sheets (MSDS), test reports, shipping tracking, and English/Spanish/Chinese technical manuals.

- References: Used by over 1,300 OEM/industrial clients worldwide, endorsed by major booth system integrators.

10. Key Takeaways & Resources

- Paint stop filter media is the industry benchmark for spray booth overspray capture, offering best-in-class dust holding, fire safety, and operating lifespan.

- Ensure compliance by choosing filters certified to ISO 16890/EN 779 and matching custom cut-sizes to your booth frames for maximum sealing.

- Upgrading to advanced glass fiber designs saves on maintenance, improves finish quality, and ensures regulatory compliance.

- Partner with certified manufacturers like Anya for full technical/supply support and global shipping.

1. European Filter Association (EFA) – Paint Overspray Control Resources

2. Paint & Coatings Industry Magazine – Filtration Tech Articles

3. Filtration+Separation Journal – Paint Filter Media Trends

4. American Filtration & Separations Society

5. Industrial Air Filtration Market Report, GrandViewResearch.com

Post time: Jul-30-2025