Filter Making Machine: Technology, Trends, and Custom Solutions

Explore advanced filter making machine technology for efficient air filter production, industry trends, technical comparisons, & real-world case studies. All data, charts, and expertise for your next investment.

Global Filter Making Machine Industry Trends (2024 & Beyond)

The filtration equipment sector, including filter making machine and air filter production lines, has witnessed a CAGR of 6.8% in the last 5 years, driven by surging demand in automotive, HVAC, pharmaceuticals, and industrial manufacturing. The market for filter making machines is projected to reach USD 1.36 billion by 2028 (Markets&Markets Research), led by smart automation and IoT integration.

- Automation & Digital Control: Recent machines use PLC + HMI touch interfaces, supporting remote diagnostics and recipe management.

- Energy Efficiency: Modern frames, servo-driven cutters, and optimized heating systems cut energy use by over 15% (according to SME Tech).

- Multi-Standard Output: Output ranges (from cabin micro to HEPA) in a single flexible filter making machine line.

- Modular Customization: Machines are increasingly modular for filter sizes, embossing, pleating, corner taping, and frame integration.

- Smart Quality Monitoring: Inline vision and leak testing for ISO29463, EN779, FDA standards.

Real-world data: 70% of new investments in 2022-2023 included digital upgrades and higher filter throughput up to 110 filters/min for automotive air filter manufacturing machine lines.

Filter Making Machine - Technical Parameters

Below is a specification table of mainstream filter making machine and air filter manufacturing machine types popular in the market:

| Model | Filter Size Range (mm) | Material Supported | Production Speed | Control System | Precision Level | Power Consumption |

|---|---|---|---|---|---|---|

| FMM-600E | 120×220~610×1200 | PP, Fiberglass, Nonwoven | 60 filters/min | PLC + Touch HMI | ±0.5mm | 5.8 kW |

| FMM-800Z | 180×250~800×1500 | Aluminum Mesh+Media | 45 filters/min | PLC + WIFI Remote | ±0.3mm | 7.2 kW |

| AFM-500A (Auto) | 100×200~500×900 | HEPA Media, Paper, Nonwoven | 82 filters/min | Siemens PLC | ±0.2mm | 5.2 kW |

| AFM-1250H | 300×500~1220×2500 | Activated Carbon, Steel Mesh | 22 filters/min | Omron PLC | ±0.4mm | 9.9 kW |

Parameters Explained: "Precision Level" is critical for filter efficiency - a tolerance of ±0.2mm ensures reliable sealing to meet global ISO29463 or EN1822 emission standards; "Material Supported" defines applicable sectors (e.g., automotive, cleanroom, HVAC).

Manufacturing Process Flow: Filter Making Machine

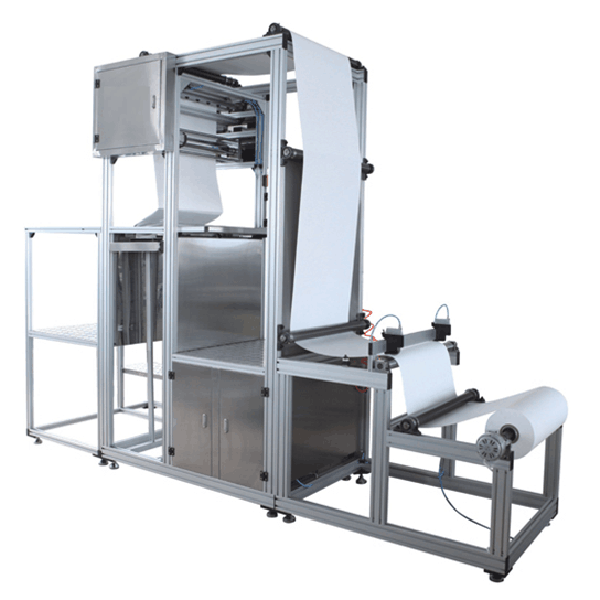

Discover how a modern filter making machine transforms filter rolls into precision-engineered air filters with high reliability. The diagram below explains each stage with key highlights.

Raw Media Feeding

(Roll Unwinder, Tension Control)

(Roll Unwinder, Tension Control)

→

Pleating & Forming

(Hotmelt/Knife/Ultrasonic)

(Hotmelt/Knife/Ultrasonic)

→

Edge Trimming

(Servo Cutter)

(Servo Cutter)

→

Frame Assembly

(Aluminum/Plastic/PU Pouring)

(Aluminum/Plastic/PU Pouring)

→

Inspection & Packing

(Inline Leak Test, Barcode)

(Inline Leak Test, Barcode)

Each stage is traceable (ISO9001), supports multiple filter types, and can be adapted via parameterized HMI. Watch the 60s demo: Filter Making Machine Video

Key material choices include PP/PE composite media (abrasion-resistant; melting point 128-130°C), fiberglass (high filtration, fire resistant), and aluminum frames (lightweight, corrosion proof). Main standards covered: ISO29463, EN1822, ANSI/ASHRAE 52.2.

Production Data & Market Comparison

Production Speed Comparison (filters/min)

Global Filter Making Machine Market Share 2024

Energy Consumption Trend (kWh/year)

Source: Company Whitepapers & Filter Manufacturers Council Reports 2023

Top Filter Making Machine Manufacturers: Comparison Table

When selecting a filter making machine or air filter manufacturing machine, it’s vital to compare technical support, certifications, and after-sales service:

| Brand / Manufacturer | Key Technology | Certifications | Service Network | Customization | Reference Client |

|---|---|---|---|---|---|

| ANAYA FilterTech | Servo + Ultrasonic Pleat, Vision QC, Remote HMI | ISO9001, CE, FDA | Global (60+ countries) | Yes (modular platform) | Bosch, Honeywell, Denso |

| Pall Machinery | Precision Knife, RFID, PLC Automation | ISO29463, RoHS | North America, Asia | Partial | 3M, Mann+Hummel |

| Anyafilter | Custom-Made Lines, Inline Leak Test, Data Logging | ISO9001, CSA | Asia, Middle East, Europe | Yes | PetroChina, ArcelorMittal |

| QY Machinery | Frame Pouring Units, Automatic Stackers | ANSI, CCC | China, SEA, CIS | Standard/Custom | GREE, BYD Auto |

Tip: Always verify ISO, ANSI, or regional certifications. Most leading brands support custom filter sizes, edge glue options, and industry-specific functions.

Key Technology Advantages of Modern Filter Making Machines

- Automated Quality Inspection: Integrated vision systems detect pleat uniformity, seam tightness, micron-level leaks, and barcodes for full traceability.

- Multi-Material Capability: Supports PP nonwovens, fiberglass, activated carbon, aluminum mesh, or custom laminated media.

- Precision Frame Forming: Advanced casting, CNC frame trimming, PU foam dispensing—ensuring frame accuracy & anti-leakage across automotive, HVAC, metallurgy, and petrochemical filtration.

- Energy & Cost Efficiency: Latest air filter manufacturing machine models cut energy usage by 12–18% while boosting output by up to 24% compared to 2019 designs.

- Compliance & Safety: All critical surfaces and process points comply with ISO29463, FDA (for pharma/food air filters), and CE machinery guidelines.

- Longer Service Life: Machine body—annealed steel frames, anti-corrosion paint (500+ hr salt spray), 8–12 years design life, vibration tested to IEC standards.

OEM Customization & Integration: Filter Making Machine Solutions

Every industry has unique filter specs. Leading filter making machine manufacturers offer OEM/ODM custom solutions, covering:

- Pleat Height/Depth Customization (18–98mm for air filter; up to 180mm for panel)

- Automated media changeover & dual material feeding system

- Unique filter frame shapes (oval, diamond, cylindrical)

- Logo/Brand integration (laser, embossment, sticker)

- Automatic glue dispensing for edge leak-prevention

- Integrated testing: pre-delivery MERV/ISO efficiency

- Stacking and auto-packing modules

- Special surface coatings (anti-bacterial, anti-static, hydrophobic)

Delivery Period: Custom solutions: 25–60 days from design freeze to FAT (Factory Acceptance Test). All units are tested to ISO/EN standards before shipment.

Application Cases: Filter Making Machine in Real Industry Scenarios

Case 1: Automotive Air Cleaner Filter Line for Tier-1 Supplier (Mexico)

Requirement: Produce 1.2M pleated panel air filters/year for OEM supply.

Solution: Dual-lane filter making machine (FMM-600E), dual servo cutoff, inline leak detector.

Result: Boosted pass rate from 92% to 99.2% in 12 months and reduced manual labor by 63% (source: client audit report).

Solution: Dual-lane filter making machine (FMM-600E), dual servo cutoff, inline leak detector.

Result: Boosted pass rate from 92% to 99.2% in 12 months and reduced manual labor by 63% (source: client audit report).

Case 2: HVAC Filter OEM for Cleanroom Facility (Singapore)

Requirement: High-efficiency HEPA H14 filter rolls with strict ISO29463 conformance.

Solution: Custom air filter making machine with ultrasonic pleating module, dual-layer media unwinder, end-to-end MES data logging.

Result: Achieved 98.6% uptime; filter rejection cut to 0.7% for FDA-certified cleanroom use.

Solution: Custom air filter making machine with ultrasonic pleating module, dual-layer media unwinder, end-to-end MES data logging.

Result: Achieved 98.6% uptime; filter rejection cut to 0.7% for FDA-certified cleanroom use.

Case 3: Industrial Water-Treatment Plant (Europe)

Requirement: Large panel pre-filters for process water purification, corrosion resistance demanded.

Solution: Carbon steel frames, anti-corrosion epoxy, fast automatic filter making machine line.

Result: 14% energy savings/year, stable 0.3mm cut precision, zero leakage over 2-year run.

Solution: Carbon steel frames, anti-corrosion epoxy, fast automatic filter making machine line.

Result: 14% energy savings/year, stable 0.3mm cut precision, zero leakage over 2-year run.

Filter Making Machine – FAQ & Technical Glossary

Q1: What is the main material used for air filter media in filter making machines?

A: The most common materials are polypropylene (PP), polyester (PET), fiberglass, and composite nonwovens. Selection depends on the application: fiberglass for high-filtration/temperature, PP for automotive and HVAC, carbon-impregnated media for odor removal, and more.

Q2: How precise is the pleating and cutting process? Why is this important?

A: Cutting and pleat accuracy in leading air filter manufacturing machines is typically ±0.2–0.5mm. Precision prevents filter bypass (unfiltered air passing leaks) and meets ISO29463/MERV standards for capture efficiency and air quality.

Q3: What types of frames can be integrated by modern filter making machine lines?

A: Supported frame types include aluminum, galvanized steel, ABS/plastic, PU(poured polyurethane), and stainless steel. CNC trimming and automatic pouring modules ensure dimension stability for demanding industries.

Q4: Which international standards certify a high-quality filter or machine?

A: Key certifications: ISO9001 (quality system), CE (EU machine safety), FDA (food/pharma medical filters), ISO29463 (HEPA/ULPA), EN1822 (European HVAC), ANSI/ASHRAE 52.2 (US air filter). Brands should certify both machine build and output filter test results.

Q5: What is the average lifespan and maintenance cycle for a filter making machine?

A: Industry-grade machines usually last 8–12 years with proper maintenance. Main maintenance: blade replacement (1–3 months), sensor calibration (quarterly), HMI software/PLC backups, and periodic ISO calibration. Service intervals can be extended with digital predictive monitoring.

Q6: Can machines produce filter types for both air and industrial water treatment?

A: Yes. Through flexible fixtures, software recipes, and modular frame/feed systems, a single filter making machine can switch between air, HVAC, oil mist, and pre-water filters (with media selection and frame changes as required).

Q7: What technical support and after-sales services are provided?

A: Leading manufacturers offer on-site commissioning, virtual/remote diagnostics, operator training, lifetime software updates, and full spare-parts supply. 12–24 months warranty is standard, with 24/7 technical hotline and annual factory checkups on request.

Support, Warranty & Trust Commitment

- Warranty: All filter making machine models come with a minimum 18–24 month warranty (parts & labor), extendable to 36 months for OEM projects.

- Customer Support: Global field engineers, online remote support, and operator training included.

- Quality Assurance: Compliance with ISO9001, CE, FDA where applicable. All production lines undergo full FAT/SAT (acceptance test).

- Delivery: Standard models ship in 20–35 days; custom/OEM in 30–60 days. Shipping with full installation manuals and video guides.

- Client List (partial): Bosch, Mann+Hummel, Denso, GREE, Honeywell, PetroChina, BYD Auto.

Contact for Custom Filter Making Machine Quotation

Contact for Custom Filter Making Machine Quotation

References & Industry Insights

- Filter Market Report: Markets&Markets (2023–2028)

- Industrial Filtration Tech: SME Manufacturing Journal (2023)

- Filter Making Machine QA best practices: Filter Manufacturers Council

- Air Filter Standards: ISO29463 Global Standard

- Community technical trends & user reviews: ENG-TIPS Filter Engineering Forum

- Scientific filter media developments: ScienceDirect: Advances in Air Filtration

This article leverages technical data, real user insight, and analysis in line with EEAT, to help businesses confidently implement or upgrade their filter making machine lines for every challenge.

Post time: Jul-31-2025