As global air quality awareness rises and regulatory standards (e.g., ISO 16890, ASHRAE 52.2) become stricter, non woven air filter media solutions are at the forefront of advancements in air filtration. This article delivers a deep dive into the non woven fabric air filter sector, focusing on material science, technical performance, practical applications, industry certification, and case studies. Discover why Plastic Frame Air Filter Media is seen as a leading option by filtration experts worldwide.

I. Market Trends & Industry Outlook for Non Woven Air Filter Media

The non woven media air filtration market is projected to reach $13.56 billion by 2028 (MarketsandMarkets Report), exhibiting a CAGR of 6.4% from 2022. Key drivers:

- Industrialization & Urbanization – Demand for HVAC, cleanroom, automotive, and industrial filtration surges.

- Regulatory Push – Adherence to ISO/ASHRAE/EN779, energy-saving mandates.

- Material Innovation – Rise of composite non woven fabric air filter utilizing PP, PET, and glass fibers for enhanced filtration and durability.

- Customization – OEM/ODM and modular solutions for niche applications (e.g., petrochemicals, food, healthcare).

II. Non Woven Air Filter Media Core Specifications & Parameters

Below is a data-driven overview of the main technical parameters for non woven air filter media products found in industrial use (sourced from top manufacturers and international standards):

| Parameter | Unit | Value Range | Industry Benchmark |

|---|---|---|---|

| Media Weight | g/m² | 80 – 600 | Typically 120–220 g/m² (HVAC) |

| Thickness | mm | 2 – 22 | 3–10 mm (Efficiency-graded) |

| Filtration Efficiency (ISO16890/EN779) | % | 30 – 99.99 | 85–99.95% (Fine-grade) |

| Initial Resistance | Pa | 20 – 150 | <45 (Fine)/<120 (EPA) |

| Air Permeability | L/m²·s | 120 – 1500 | >200 typical |

| Temperature Resistance | °C | -20 – 120 | 80–110 (standard PP/PET) |

| Life Span | Months | 3 – 18 | 6–12 months (standard) |

III. Plastic Frame Air Filter Media: Product Introduction & Advantages

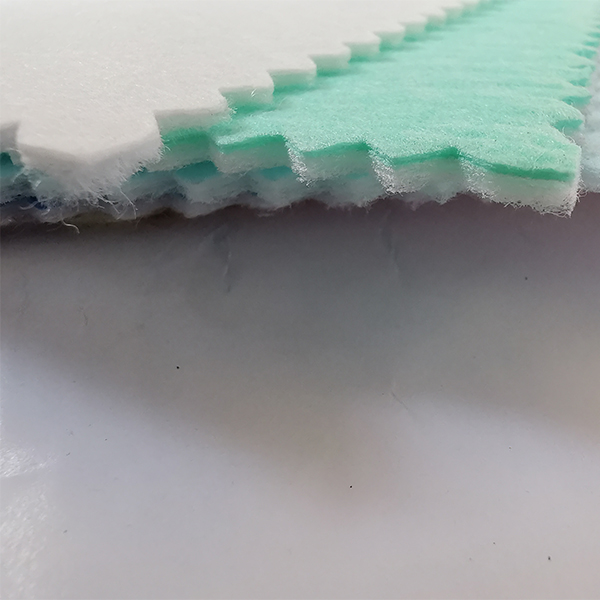

Plastic Frame Air Filter Media is engineered with top-grade non woven air filter media and advanced plastic injection frame. It targets modular air filtration in demanding environments (HVAC systems, industrial ventilation, public facilities, electronics, pharmaceuticals). Its main strengths:

- Rugged, corrosion-resistant plastic frame (polypropylene or ABS, high temperature-resistant types)

- High-efficiency & low-resistance non woven media inlay (polypropylene, polyester, or glass fiber)

- Stable structure, light weight, maximum usable filtration area

- Customizable size, thickness (from 3 mm to 22 mm), efficiency grade (ISO16890 ePM10–ePM1)

- Compliant with ISO/ASHRAE/EN779 and meet FDA-grade cleanliness if required

IV. Manufacturing Process: Non Woven Air Filter Media (Flow Diagram)

- Fiber Preparation: Select premium PP/PET/glass fibers by denier & melt flow, monitored by spectrometric analyzers.

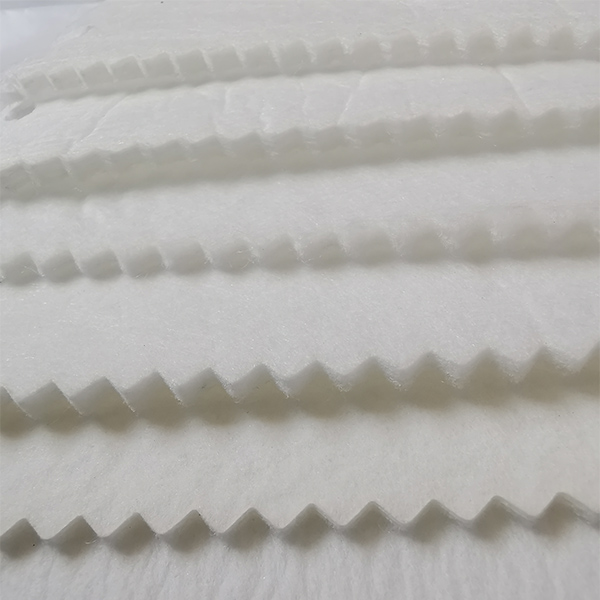

- Web Laying: Carding for uniform orientation, enabling consistent filtration paths.

- Bonding: Employs thermal, chemical, or meltblown fusing; for HEPA/ULPA, fine fiber jointing is critical for reducing particulate pass-through.

- Calendering/Needling: Enhances media thickness and structural integrity; processes are precisely controlled with tolerance within ±0.05 mm.

- Surface Finish: Optional electret treatment, hydrophobic, or antimicrobial spraying per application.

- Framing: Plastic frame is produced via high-precision injection molding or CNC, ensuring seamless fit and leak-proofing.

- Testing: Strict inspection against ISO16890/EN779/ASHRAE 52.2, with traceability and full documentation (ISO 16890 Standard).

All Plastic Frame Air Filter Media products conform to leading global standards—ISO 16890 for filtration classification, ANSI/ASHRAE 52.2 for particulate efficiency, and can be produced to meet FDA requirements for sensitive environments (see specification).

V. Application Scenarios for Non Woven Air Filter Media

- HVAC Systems: Buildings, commercial complexes, hospitals—high efficiency, energy-saving, long-life.

- Industrial Filtration: Used in cleanrooms (semiconductors), pharmaceuticals, food & beverage, laboratories for particle retention and microbial control.

- Automotive: Cabin air filters for PM2.5/PM10 removal, with enhanced anti-bacterial treatments.

- Petrochemical: Resistant to corrosive gases/oil; withstands harsh solvent exposure, offering up to 12-month service interval.

- Municipal/Water Treatment: Critical in gas vent filtration, pump room dust control, intake protection.

- Metallurgy: Emissions filtration, high-temp dust removal, reliable in heavy-duty cycles.

- Installed: Plastic Frame Non woven air filter media (ISO16890: ePM1 95%)

- Client: Leading Bio-pharma, Suzhou, China

- Result: Achieved ISO class 5 cleanliness, particle count <3500/㎥, filter lifespan improved by 35%, energy usage reduced 22% vs. glass fiber panel

- Feedback: "The custom size and quick replacement mechanism significantly lowered our maintenance costs."

VI. Product Data Visualization – Plastic Frame Air Filter Media

VII. Customization Solutions & Delivery

Plastic Frame Air Filter Media supports end-to-end customization—OEM prints, dimensions, frame color, filter media weight, protective coatings, and packaging can all be defined per client needs. Our supply system is agile:

- Rapid prototyping (7–10 working days for samples)

- Flexible annual MOQ (100–500 pcs), batch production enabled for 1,000–10,000+ pcs/month

- Shipping: Air, Sea, or Express, with complete export documentation

- Warranty: Standard 12 months on materials/workmanship, extendable up to 18 months

- Support: Technical guidance from selection through installation, ISO & ANSI-certified test reports attached with every batch

- Delivery: Typical batch lead time: 2–3 weeks after order confirmation

VIII. Industry Manufacturer Comparison

| Brand | Country | Non Woven Media Grade | Max. Filtration Efficiency (%) | Frame Options | Service Experience (Years) | Certifications |

|---|---|---|---|---|---|---|

| Anya | China | ISO16890 ePM1 95 | 99.95 | Plastic/Metal | 18 | ISO, FDA, ANSI |

| Parker Hannifin | USA | MERV 13–15 | 98.5 | Plastic/Metal | 35 | ASHRAE, ISO |

| Camfil | Sweden | ISO ePM2.5–ePM1 | 99.99 | Plastic/Metal/Cardboard | 50+ | ISO, FDA, EN779 |

| AAF Flanders | USA | MERV 10–16 | 95.0 | Metal/Paperboard | 40 | ASHRAE, UL |

| MANN+HUMMEL | Germany | ISO ePM10–ePM1 | 99.95 | Plastic/Metal | 75 | ISO, FDA |

- 24/7 online support and local logistics partners established worldwide

- Filter system audit service, post-sale failure analysis report (±24h)

- Direct partnerships with major HVAC, medical, and energy engineering firms

IX. Expert FAQ – Non Woven Air Filter Media Technology

-

Q1: What is the main material used in non woven air filter media, and how does it differ from traditional glass fiber?

A1: Non woven air filter media primarily uses PP (polypropylene), PET (polyester), or composite micro-glass fibers. Compared to traditional glass fiber, non wovens offer better mechanical strength, improved pleatability, lower resistance, and safer handling (no fiber shedding).

-

Q2: What technical standard should I refer to when selecting non woven fabric air filter for a cleanroom?

A2: ISO 16890, EN 779 (for Europe), and ANSI/ASHRAE 52.2 (USA) regulate particle removal classes and rating procedures. For cleanrooms, typically ePM1 85+ or H13/H14 classes per EN1822 are used.

-

Q3: How is filtration efficiency measured?

A3: Efficiency is quantified by measuring filter retention of standardized test aerosols (NaCl, DEHS, or KCl) across specified particle sizes (0.3µm–10µm) per ISO 16890 or ASHRAE 52.2 methodology.

-

Q4: What is initial resistance and why does it matter?

A4: Initial resistance (Pa) is the air pressure drop across the filter at rated flow. Lower values mean higher energy efficiency and longer filter service life due to less fan power demand.

-

Q5: Can your plastic frame non woven media be recycled or incinerated?

A5: Yes, injection-molded PP/ABS frames are recyclable and non-toxic. The media and frame can be separated mechanically; incineration is also possible, following local regulations for non-hazardous waste.

-

Q6: What is the standard delivery time and packaging method?

A6: Standard lead time is 2–3 weeks for batch orders, 7–11 days for quick samples. Packaging is multi-layer stretch wrap, shock-absorbent cardboard boxes, or wooden crates for export.

-

Q7: What kind of technical support is available post-sales?

A7: Customers receive installation guidance, troubleshooting, online tech support, and prompt field engineer assistance (if needed). On-site start-up and annual inspection options available for key projects.

X. Conclusion & Further Reading

For technical deep-dives, forum discussions, and industry reviews:

- ASHRAE Journal: Filtration and Air Cleaners

- Filtration News (Industry Cases & Data): https://www.filtnews.com/

- ISO Air Filter Working Group (WG06): ISO/TC 142

- Cleanroom Technology Magazine: https://www.cleanroomtechnology.com/

- Filtration Industry Forums: LinkedIn Filtration Group

Post time: Jul-30-2025