Filter Making Machine: Insider Notes, Real Specs, and What Buyers Are Asking

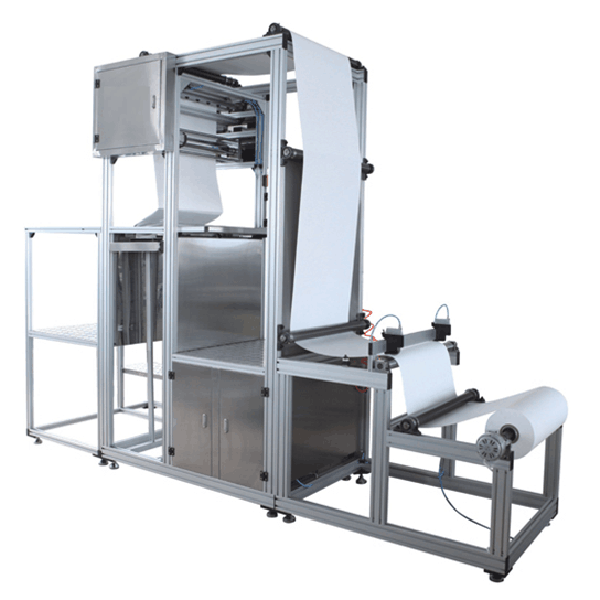

I’ve toured factories from Pune to Prague, and the first line I check is the Filter Making Machine. It’s the heartbeat of air, oil, cabin, and HEPA production. The unit from No.580 Gongnong Road, Shijiazhuang City 050000, Hebei, P.R. China, has been popping up more in my notes—partly because it mixes sensible engineering with pragmatic automation. And, to be honest, because maintenance teams keep telling me it “just runs.”

What it is (and why it matters)

Fully or semi-automatic, PLC touchscreen, accurate pleating/cutting/assembly, high-speed, and compatible with paper, nonwoven, fiberglass, and mesh. It sounds standard—until you see the consistent pleat geometry at higher speeds. In fact, many customers say geometry stability is where cheaper lines fall short.

| Specification | Typical Value (≈, real-world use may vary) |

|---|---|

| Pleat height range | 10–120 mm (paper/nonwoven); 20–100 mm (fiberglass) |

| Web width | ≤ 1,000–1,200 mm options |

| Line speed | ≈ 8–35 m/min (material dependent) |

| Cutting accuracy | ±0.3–0.5 mm |

| Glue system | Hot-melt slot or swirl; optional dual-bead |

| Control | PLC + 7–12” touchscreen HMI |

| Utilities | 380–415V 3φ; air 0.6–0.8 MPa |

Process flow (how shops actually run it)

- Material unwind & tension control (paper/nonwoven/fiberglass/mesh).

- Pleating: blade or rotary; spacer or separator options for fiberglass.

- Hot-melt application: bead, dot, or curtain depending on filter design.

- Trimming & cross-cutting; edge sealing.

- Assembly: end-cap potting (PU/epoxy) and core insertion if needed.

- Curing (temperature/time recipes).

- Testing: efficiency per ISO 16890/EN 1822; pressure drop; burst/leak.

- Packing, labeling, and traceability via PLC data export.

Service life benchmarks: HVAC MERV 13 ≈ 6–12 months; HEPA H13 ≈ 12–24 months (cleanrooms vary); automotive oil filters ≈ 10,000–20,000 km. I guess it depends on dust load and duty cycles more than anything.

Standards, tests, and sample data

- HVAC filters: ASHRAE 52.2 MERV 8–16; pressure drop at 1.0–1.5 in.wg typical limits.

- HEPA/ULPA: EN 1822 H13 ≥99.95% (MPPS); leak test with aerosol scan.

- ISO 16890 ratings (ePM1/ePM2.5); UL 900 for flammability; automotive lines chasing IATF 16949 traceability.

Recent lot I reviewed: MERV 13 at 0.3–1.0 μm efficiency ≈ 75% initial; ΔP ≈ 110 Pa at 1.8 m/s; HEPA H13 panel averaged 99.97% MPPS with no detectable leaks. Not bad.

Where it’s used

Cleanrooms and pharma, HVAC for commercial buildings, spray booths, engine intake, oil and hydraulic circuits, and automotive cabin filters. Some shops are moving to glass-free ePM1 media for sustainability—surprisingly, the Filter Making Machine handles the shift with only minor glue lane tweaks.

Vendor snapshot (my quick take)

| Vendor | Strengths | Watch-outs |

|---|---|---|

| Anya (this Filter Making Machine) | Solid pleat stability; PLC UX is friendly; custom fixtures fast | Lead times spike ahead of HVAC season |

| Vendor A | Top-tier servo control; broad global service | Price premium ≈ 15–25% |

| Vendor B | Budget-friendly starter lines | Glue metering variability at high speeds |

Customization options

Changeover kits for different pleat heights, recipe-driven glue patterns, quick tooling for PU vs. epoxy potting, and MES/ERP data hooks. For fiberglass HEPA, request heated platens and separator feeds. For oil filters, add burst/impulse test stands inline.

Field notes and feedback

A Central Europe HVAC plant cut scrap ≈ 9% by switching to adaptive tension control. An auto supplier in ASEAN reported 18% higher OEE after a semi-auto to full-auto upgrade. Operators like the alarm diagnostics; maintenance appreciates off-the-shelf pneumatics.

Bottom line

If you’re scaling HVAC or stepping into HEPA, this Filter Making Machine earns a look. It’s not flashy—actually that’s the point. Stable, configurable, serviceable. Run a trial with your media; check pleat recovery and ΔP consistency across speeds before signing. Old-school advice, still works.

Citations

Post time: Oct-21-2025