Filter Paper For Oil Filtration is a key solution in the manufacturing industry, specifically within Paper and paper products industry and Manufacturing of industrial filter paper and materials. This article explores how ANYA FILTER MEDIA CO., LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Filter Paper For Oil Filtration Overview

- Benefits & Use Cases of Filter Paper For Oil Filtration in Manufacturing of industrial filter paper and materials

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Filter Paper For Oil Filtration from ANYA FILTER MEDIA CO., LTD

Filter Paper For Oil Filtration Overview

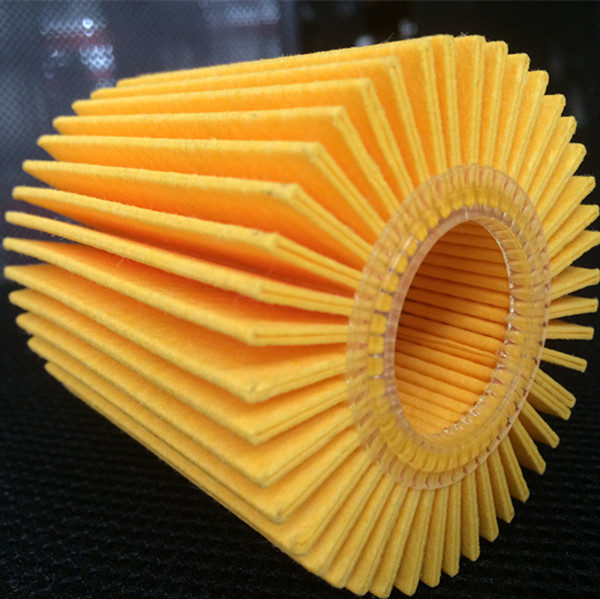

Filter Paper For Oil Filtration is a precision-engineered media designed to remove particulates, varnish precursors, and sludge from industrial lubricants, hydraulic fluids, cutting and grinding oils, and compressor or gearbox oils. In the paper and paper products industry—particularly within the Manufacturing of industrial filter paper and materials—this media underpins reliable production by protecting pumps, valves, bearings, and tooling from abrasive fines. Engineered from high-purity cellulose or cellulose–synthetic blends, the media’s pore structure and resin system deliver a stable balance of flow, efficiency, and dirt-holding capacity for both pleated elements and flat-bed/gravity filter systems used in paper filter oil applications.

- Technical profile and options include: cellulose or synthetic filter paper blends; basis weights typically 80–200 gsm; controlled micron ratings (approx. 5–60 μm); surface and depth-loading structures; phenolic or acrylic resin impregnation for high wet strength; and temperature resistance tailored to mineral and synthetic oils.

- Form factors: pleatable media for spin-on and cartridge oil filters, plus roll goods for gravity-bed and vacuum filter units on central coolant systems.

- ANYA FILTER MEDIA CO., LTD provides tight tolerance control, consistent caliper, and customizable widths/roll lengths—backed by application engineering and lab testing to match target cleanliness levels and ΔP limits.

Benefits & Use Cases of Filter Paper For Oil Filtration in Manufacturing of industrial filter paper and materials

Across metalworking, pulp & paper, powertrain, and general industrial plants, Filter Paper For Oil Filtration supports centralized coolant filtration, roll and sheet-fed gravity filters, vacuum drum filters, and pleated lube/hydraulic elements. In cutting, honing, and grinding, the right paper filter oil grade captures fines and swarf without starving the process, safeguarding surface finish and tool life. In hydraulic and lube circuits, synthetic filter paper or blended grades provide stable efficiency with minimal collapse risk under cyclic flow and temperature changes.

- Key advantages: consistent pore size for predictable cleanliness; high dirt-holding capacity to extend change-out intervals; strong wet tensile/burst strength for line reliability; and optimized permeability to control ΔP and energy consumption.

- Competitive edge: customizable cellulose–synthetic blends, resin systems tuned to oil chemistry, and tailored grammage/caliper for specific equipment and target ISO cleanliness codes.

- ANYA FILTER MEDIA CO., LTD pairs materials expertise with process know-how—supporting trials, rapid prototyping, and private-label programs to help OEMs and end users accelerate qualification and scale-up.

Cost, Maintenance & User Experience

Total cost of ownership hinges on media life, stability of pressure drop, and disposal volume. By selecting the appropriate grade of Filter Paper For Oil Filtration—cellulose or synthetic filter paper blends matched to viscosity, temperature, and contaminant load—plants typically see fewer changeouts, longer oil life, and improved uptime. Fewer roll replacements on gravity beds reduce labor costs and unplanned stoppages; in pleated elements, higher dirt-loading delays ΔP alarms and helps maintain energy-efficient pump operation.

- ROI drivers: extended service intervals, stabilized surface finish/part quality, lower scrap, and reduced oil top-ups due to better contaminant control. Many users report double-digit reductions in consumables and maintenance hours after optimizing media grade and basis weight.

- User feedback from paper & paper products industry operations highlights predictable roll consumption, clean unwind/rewind behavior, and consistent caliper—key factors for automated roll-change systems and steady filtration throughput.

Sustainability & Market Trends in manufacturing

Sustainability priorities—waste minimization, longer fluid life, and lower energy consumption—are reshaping filtration media choices. Right-sizing Filter Paper For Oil Filtration reduces roll waste and disposal frequency, while stable permeability helps cut pumping energy by avoiding excessive ΔP. As regulations tighten around shop-floor emissions and fluid handling, more manufacturers are adopting media that balances efficiency with throughput to maintain ISO cleanliness targets without over-filtering.

- Market trend: a shift toward engineered blends and low-VOC resin systems, plus growing interest in responsible fiber sourcing and incinerable waste streams for energy recovery.

- ANYA FILTER MEDIA CO., LTD is investing in media development that enhances life-cycle performance—optimizing grammage, resin chemistry, and calendering to deliver fewer changeouts and lower total waste, aligning reliability with environmental goals.

Conclusion on Filter Paper For Oil Filtration from ANYA FILTER MEDIA CO., LTD

Filter Paper For Oil Filtration is a critical enabler of equipment reliability, process stability, and cost control across manufacturing—especially within the paper and paper products industry and the Manufacturing of industrial filter paper and materials. With engineered cellulose and synthetic filter paper options, ANYA FILTER MEDIA CO., LTD delivers consistent quality, application-specific performance, and dependable supply. If you’re optimizing gravity-bed or pleated systems—or benchmarking a paper filter oil grade for a new line—our team can help you select and validate the right media.

- Explore the product range: https://www.anyafiltermedia.com/industrial-paper-for-oil-filters.html

- Contact us: email: sales@anyafiltermedia.com

- Visit our website: https://www.anyafiltermedia.com

Post time: Oct-22-2025