fiberglass media,fiberglass filter media,fiberglass filter cloth is a key solution in the industrial manufacturing industry, specifically within Manufacturing of filtration equipment and components and Filter material manufacturing. This article explores how ANYA FILTER MEDIA CO., LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- fiberglass media,fiberglass filter media,fiberglass filter cloth Overview

- Benefits & Use Cases of fiberglass media,fiberglass filter media,fiberglass filter cloth in Filter material manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in industrial manufacturing

- Conclusion on fiberglass media,fiberglass filter media,fiberglass filter cloth from ANYA FILTER MEDIA CO., LTD

fiberglass media,fiberglass filter media,fiberglass filter cloth Overview

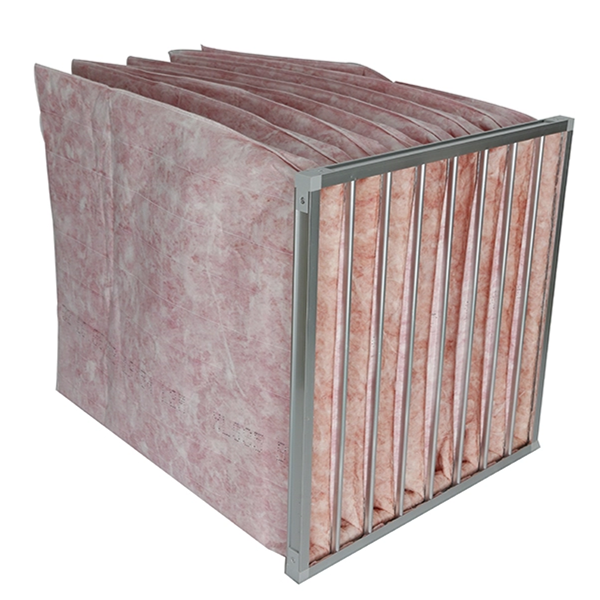

In industrial filtration, fiberglass media—also referred to as fiberglass filter media and fiberglass filter cloth—delivers a durable, heat-stable, and efficient solution for capturing airborne particulates. Produced from fine micro-glass fibers formed into a uniform nonwoven, this media offers high dust-holding capacity with low initial resistance, making it ideal for prefilters, pocket/bag filters, and downstream protection of HEPA/ULPA stages. For filter material manufacturing, its consistent pore structure and dimensional stability reduce variability in converting, welding, and stitching processes.

ANYA FILTER MEDIA CO., LTD engineers fiberglass filter media with attention to fiber distribution, binder formulation, and backing options (e.g., scrim support) to meet demanding B2B specifications. Roll widths, basis weights, and efficiency grades can be tailored to align with ISO 16890 and ASHRAE performance targets, supporting OEMs and converters across HVAC, paint spray, industrial ventilation, and process filtration. In a recent deployment for a paint finishing line, a switch to ANYA’s fiberglass filter media helped the customer stabilize pressure drop over longer run times, reducing unplanned changeouts and improving booth uptime—key gains for throughput-focused operations.

Benefits & Use Cases of fiberglass media,fiberglass filter media,fiberglass filter cloth in Filter material manufacturing

Filter material manufacturers rely on fiberglass filter media for its balance of efficiency, strength, and processing friendliness. Typical use cases include pocket/bag filters in HVAC systems, multi-layer composites for paint mist capture, and protective prefiltration in clean production zones. Fiberglass filter cloth formats are leveraged where higher temperature tolerance and chemical stability are needed, while lofted fiberglass media provides graded density for high dust-loading applications.

Competitive advantages for manufacturers include: predictable caliper and basis weight for precise pocket formation; options for scrim reinforcement that enable reliable ultrasonic welding or stitching; resin systems engineered for durability across humidity and temperature swings; and stable roll geometry that reduces scrap and line stoppages. ANYA FILTER MEDIA CO., LTD brings deep converting expertise—supporting custom lamination, slitting, and packaging—to integrate fiberglass media seamlessly into your existing equipment. The result is faster setup, fewer defects, and consistent filter performance across large production batches, helping B2B decision makers standardize SKUs and streamline supply chains.

Cost, Maintenance & User Experience

Total cost of ownership hinges on media life, energy consumption, and production yield. Fiberglass media supports attractive ROI by sustaining low resistance over time, extending service intervals and reducing labor and consumable costs. For manufacturers, its runnability—clean edge slitting, minimal fiber shedding, and robust scrim options—reduces downtime and scrap, improving overall equipment effectiveness (OEE). When filters last longer and maintain stable pressure drop, end users realize measurable savings in fan energy and changeout frequency.

Customers in the manufacturing of filtration equipment and components report smoother pocket formation, stronger seams, and consistent efficiency lot-to-lot when deploying ANYA FILTER MEDIA CO., LTD solutions. Procurement teams value predictable lead times, flexible MOQs, and technical support during line trials. Maintenance teams appreciate that fiberglass filter cloth and fiberglass filter media resist deformation under load and temperature, keeping filters dimensionally true in service. Collectively, these factors drive a compelling lifecycle ROI, making ANYA’s fiberglass media a low-risk, high-value specification for OEMs and retrofit programs alike.

Sustainability & Market Trends in industrial manufacturing

Across industrial manufacturing, energy-efficient air handling and compliant air quality are now board-level priorities. Regulations and frameworks such as ISO 16890, ASHRAE standards, and regional energy codes are pushing higher filtration effectiveness with the lowest feasible pressure drop. Fiberglass filter media aligns well with these goals: its stable fiber matrix delivers dependable efficiency with minimal performance drift, helping systems run efficiently and cutting avoidable emissions linked to fan energy.

ANYA FILTER MEDIA CO., LTD advances sustainability by optimizing media structures for longer service life, offering low-VOC binder options, and supporting right-sized packaging to reduce transport emissions. As markets expand—driven by EV battery lines, advanced coatings, data centers, healthcare, and precision manufacturing—demand is growing for fiberglass media and fiberglass filter cloth that balance efficiency, durability, and processability. ANYA’s ongoing R&D, QA traceability, and application engineering position the company as a forward-looking partner that helps B2B decision makers meet ESG targets without compromising throughput or quality.

Conclusion on fiberglass media,fiberglass filter media,fiberglass filter cloth from ANYA FILTER MEDIA CO., LTD

For industrial manufacturing and filter material manufacturing, fiberglass media—whether specified as fiberglass filter media or fiberglass filter cloth—delivers the consistency, longevity, and processing ease that OEMs and converters require. ANYA FILTER MEDIA CO., LTD combines materials expertise, manufacturing discipline, and responsive service to help you achieve predictable performance and lower lifecycle costs across diverse applications.

Ready to evaluate or specify?

- "Contact us: email: sales@anyafiltermedia.com

- "Visit our website: https://www.anyafiltermedia.com"

Post time: Oct-06-2025