What’s Behind Today’s Cleanroom-Grade Fiberglass Media

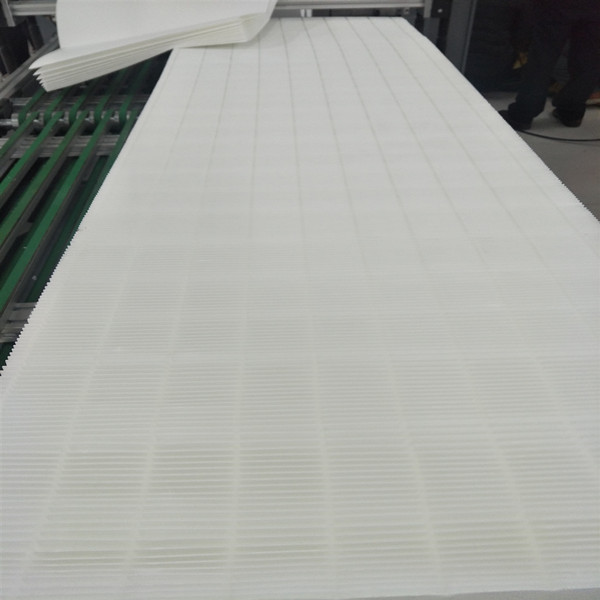

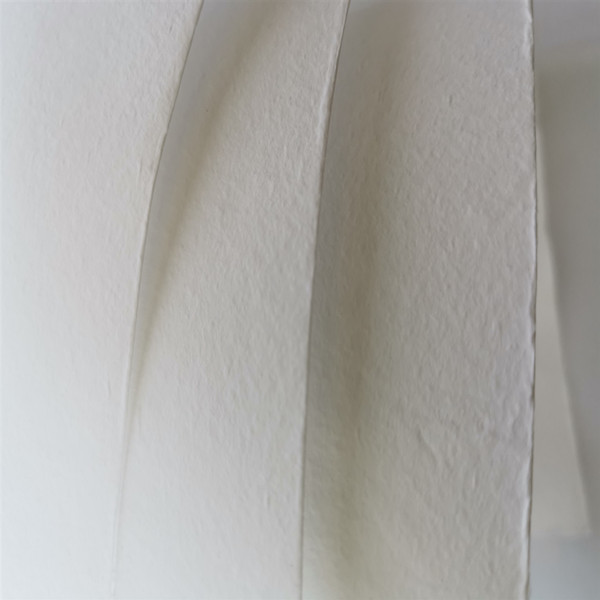

If you work around semiconductor lines or hospital isolation rooms, you probably hear this phrase a lot—and for good reason: fiberglass media filter. It’s the quiet hero inside H14 HEPA packs. I’ve toured a few factories, and honestly, the better papers feel almost “silky”—thin, uniform, and stubbornly consistent under lab lights.

Industry snapshot

Demand is climbing thanks to EU GMP Annex 1 updates, booming battery plants, and new hospital air-change targets. Many customers say procurement’s gotten picky: verified EN 1822 H14 performance, batch COAs, and traceability as baseline—not “nice to have.” It seems that post-2020, validation audits got sharper.

Featured media: Glassfiber Filter Media Cleanroom HEPA Filter Paper Media H14

Made in Shijiazhuang, Hebei (No.580 Gongnong Road, 050000), this sheet is positioned for H14 final filters in pharma, biotech, and electronics. To be honest, the vendor’s openness about payment methods—MoneyGram, Western Union, bank transfer, PayPal—signals a wholesale-first model.

| Parameter | Typical spec (H14) | Notes |

|---|---|---|

| Efficiency @ MPPS (EN 1822) | ≥ 99.995% | ISO 29463 equivalent; real-world use may vary |

| Pressure drop @ 5.3 cm/s | ≈ 110–140 Pa | Media-only, lab conditions |

| Basis weight | ≈ 60–90 g/m² | Grade-dependent |

| Fiber diameter (mean) | ≈ 0.5–1.5 µm | Electrostatic-neutral glass |

| Roll width / ID | ≤ 1000 mm / 3 in | Custom slitting available |

| Temp / humidity | ≤ 80°C continuous; RH ≤ 95% (non-condensing) | Avoid liquid water; check binder compatibility |

How it’s made (short version)

Materials: micro-glass fibers, aqueous binders, wet-laid on a forming wire. Methods: dispersion control, sheet formation, drying/curing, calendering. Testing: EN 1822 part 3 media scans; MPPS challenge; Gurley air resistance; burst; pinhole light tests. Service life: depends on upstream prefilters—many OEMs design for 1–3 years in cleanrooms, but I’ve seen 6–12 months in harsher fabs.

Where it’s used

- Terminal H14 boxes in ISO Class 5–7 suites

- Fan filter units over lithography tools

- Hospital isolation rooms and BSC upgrades

- Battery, pharma fill-finish, optics assembly

Why choose fiberglass media filter paper over synthetics? Heat tolerance, long-term stability, and predictable MPPS behavior. However, synthetics can win on splash resistance; horses for courses.

| Vendor | HEPA classes | Certifications | MOQ / lead time | Notes |

|---|---|---|---|---|

| Anya Filter Media (Hebei) | H10–H14 | EN 1822, ISO 29463 COA; RoHS/REACH | Wholesale; 10–20 days | Flexible payment; custom slitting |

| Vendor B (EU) | H13–U15 | EN 1822; UL 900; ISO 9001 | Medium MOQs; 3–5 weeks | Deep validation pack |

| Vendor C (US) | H11–H14 | IEST test reports; UL 900 | Short runs; 2–4 weeks | Fast sampling |

Customization and QC

Options: roll width slitting to ±1 mm, basis-weight tuning, hydrophobic top-coat, and low-boron glass for sensitive lines. QC includes MPPS efficiency mapping, pressure-drop curves, and pinhole inspection. Typical batch COA lists H14 ≥ 99.995% and media ΔP vs. face velocity charts.

Two quick case notes

- Pharma fill-finish (EU): swapped to fiberglass media filter H14 paper; leak test rejects fell from 7.8% to 1.2% over three quarters.

- Li-battery dry room: H14 with tighter basis weight variance cut FFU power by ≈ 6% at same ACH—small change, real savings.

Standards and proof

Look for EN 1822:2019 and ISO 29463 media tests, plus IEST-RP-CC001 guidance for assembled filters. For safety, UL 900; for compliance, RoHS/REACH. A decent lab report will show MPPS determination, upstream/downstream counts, and uncertainty budgets—nerdy, but auditors love it.

References:

- EN 1822-1:2019 High efficiency air filters (EPA, HEPA, ULPA)

- ISO 29463:2017 High-efficiency filters and filter media

- IEST-RP-CC001: HEPA and ULPA Filters

- ASHRAE 52.2: Method of Testing General Ventilation Air-Cleaning Devices

Post time: Oct-05-2025