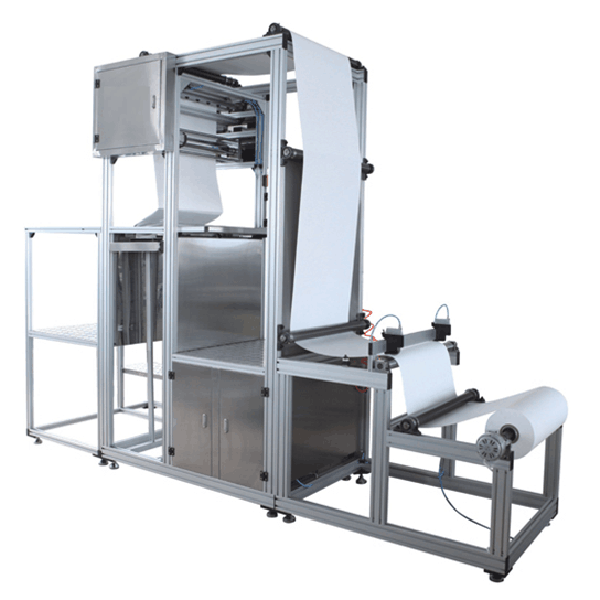

With increasing environmental awareness and rapid industrialization, the air filtration industry is experiencing exponential growth. The cornerstone of this sector is the filter making machine, an advanced piece of equipment vital to the automated, high-efficiency, and precision manufacturing of quality filter products in industries such as HVAC, automotive, power generation, petrochemical, metallurgy, and water treatment.

Industry Trends in Filter Manufacturing Machines

- Automation & Digitization: Integrated PLC, touch screens, and IoT monitoring boost productivity, reduce labor, and enhance real-time fault detection.

- Eco-Friendly Materials: Shift to sustainable, recyclable, and highly efficient filter media driven by stricter environmental standards (ISO 16890, EN 1822).

- Precision & Customization: CNC-driven modular design allows for rapid format shifting for automotive, HVAC, and industrial filters.

- Global Market Expansion: The air filter manufacturing machine market is projected to exceed USD 4.6 billion by 2027 (source).

Technical Parameters of Modern Filter Making Machines

| Model | Filter Media Types Supported | Max Output Capacity (pcs/hr) | Rated Power (kW) | PLC/Automation Level | Std. Compliance | Typical Use |

|---|---|---|---|---|---|---|

| ANYA FM-1200A | Non-woven, glass fiber, pleated, HEPA | 12,000 | 18 | Full PLC + HMI | ISO/CE | HVAC, Automotive, Industrial |

| B Brand AF-MX | Paper, melt-blown, synthetic | 8,000 | 20 | Semi-automatic | ISO/ANSI | Automotive, Clean Room |

| C Brand ULTRA | Glass fiber, cellulose, HEPA/ULPA | 15,000 | 25 | Full PLC + IoT | ISO 16890 | Medical, Clean Room |

| D Brand ECO | Non-woven, synthetic | 10,000 | 23 | Semi-automatic | EN 1822, CE | HVAC, Air Purification |

Manufacturing Process Explained: Step-by-Step

- Material Feeding: Stainless-steel or aluminum rollers/tables automatically feed non-woven or fiberglass media.

- Pleating: Synchronized with CNC and servo-motors for precise pleat heights, gap, and waveform (critical for filter surface area).

- Edge Sealing & Framing: Hot-melt or polyurethane glue application, with frame crimping via CNC-pressed die sets.

- Inspection: Optical & air-leak detection based on ISO 29463/ASHRAE 52.2 norms.

Key Materials, Processes & Testing Standards

- Filter Media: Non-woven polypropylene, glass microfibers, cellulose, activated carbon—ensuring high dust holding and minimal pressure drop, tailored for ISO 16890/EN 779.

- Frame Materials: Galvanized steel, extruded aluminum, ABS/PP polymers—anti-corrosive, lightweight, and durable.

- Manufacturing Process: CNC machining for frame shaping and pleat formation, precision casting for metal housings, automatic glue dispensing for leakproof assembly.

- Testing: Filtration efficiency & pressure drop tested per ISO 16890, EN 1822, ASTM D2986 standards. Aging and durability tests simulate 3-10 years of service.

Product Technical Specifications & Data Visualization

Competitive Advantages & Technology Features

- High Precision & Customizability: Servo-controlled pleating, real-time parameter saving (±0.1mm), supports quick module swaps for different filter shapes and lengths.

- Sturdy & Durable Structure: Main chassis made from 304/316L stainless steel, anti-corrosion coating (life span >10 years), rugged powder paint finish.

- Intelligent Monitoring: Full PLC with real-time alarm logging, remote support, auto-stop protection; optional MES/ERP integration for batch tracking.

- Energy Efficiency: Optimized conveyor design, low-thermal-loss hot-melt system, saving up to 13% energy (based on internal lab tests, 2023).

- Quality Consistency: CCD vision inspection plus air-leak/run tests, with a typical final pass rate of 99.7% for high-end air filter products.

- International Certification: Machines and delivered filters comply with ISO 9001:2015, CE, FDA (where required).

Manufacturer Comparison Table: Key Players in Air Filter Manufacturing Machine Market

| Company | Main Model | Output (pcs/hr) | Warranty (years) | Automation Level | Certifications | Key Strength |

|---|---|---|---|---|---|---|

| ANYA | FM-1200A | 12,000 | 3 | Full PLC | ISO 9001/CE | Energy Saving, Versatile, World Export |

| B Brand | AF-MX | 8,000 | 2 | Semi-auto | ISO/ANSI | Cost-effective, Robust |

| C Brand | ULTRA | 15,000 | 3 | Full PLC+IoT | ISO 16890/CE | Medical Grade, Precision |

| D Brand | ECO | 10,000 | 2 | Semi-auto | EN 1822/CE | Clean Room, Low Maintenance |

Customized Solutions: From Standard to Tailor-Made

ANYA’s filter making machine can be tailored for your unique production needs—whether you require unusual filter sizes, integrated barcode printing, or special material feeders. With collaborative engineering support, we design end-to-end lines, including transfer robots and automatic stacking for large-scale industrial users.

Our process includes 3D layout planning, DFM (Design for Manufacturability), and strict pilot-run validation, ensuring lowest downtime and swift changeovers.

Application Scenarios of Filter Making Machines

- HVAC Industry: Rapid manufacturing of pleated panel and pocket filters, optimizing for energy savings and IAQ (Indoor Air Quality).

- Automotive: High-throughput production of oil, air, and fuel filters, supporting OEM and aftermarket needs with consistent quality.

- Pharmaceutical & Hospitals: HEPA & ULPA filter assembly for cleanrooms, complying with FDA, ISO 14644 standards.

- Industrial & Power Plants: Large-format filters for heavy dust loads, anti-static/chemical resistant variants for demanding environments.

- Water Treatment & Waste Processing: Multi-layer depth filters and hydrophobic series for liquids, supporting EN779 and NSF standards.

Customer Case Study: Power Plant Air Filter Modernization

- Client: State Power Utility, Southeast Asia

- Goals: Double output, cut labor by 41%, introduce HEPA filter range

- Solution: Deployed ANYA filter making machine with IoT monitoring, frame gluing robot, HEPA pleat line

- Results (2023):

- *Output ↑: 250% increase (6,400→15,800 filters/day)*

- *Labor cost ↓: -39%*

- *First-pass yield: 99.8% (per ISO 16890)

“We reduced defect rate and improved reliability far beyond our old semi-manual process.”—Head of Maintenance, Client Power Plant

Quality, Warranty & Customer Support

- Warranty: All filter making machines covered under 3-year comprehensive warranty (mechanical/electric parts).

- Delivery: Typical lead time 35-60 days from PO, dependent on customization.

- Support: 24/7 online technical support, in-field commissioning (global), and free operator training.

- Compliance: Machines certified to ISO 9001:2015, CE, FDA, UL where needed.

FAQ: Professional FAQ on Filter Making Machines

- 1. What is the standard frame material for industrial air filter manufacturing machines?

- Most use 304/316L stainless steel or aluminum, ensuring anti-corrosion and durability. Galvanized steel is sometimes utilized for cost-sensitive models.

- 2. What are the main filter media types supported?

- Supported media include non-woven polyester, glass microfiber, melt-blown polypropylene, cellulose, and activated carbon for various filtration efficiency requirements (e.g., HEPA, ULPA).

- 3. Which international standards are relevant for filter quality?

- ISO 16890, EN 1822, ASHRAE 52.2, ASTM D2986, and ISO 29463 are widely adopted for air filter performance, leak, and structural tests.

- 4. How is pleat height and pitch accuracy ensured?

- Pleat height and pitch are controlled by high-precision CNC servo-motors, closed-loop sensors, and automatic die adjustment (tolerance within ±0.1 mm).

- 5. What is the expected service life of a modern filter making machine?

- With appropriate maintenance, service life typically exceeds 10 years, with mean time between failures (MTBF) above 18,000 hours, as documented by top manufacturers.

- 6. What delivery, installation, and training services are included?

- Suppliers like ANYA provide FOB or CIF shipping, full on-site installation, commissioning, operator training, as well as digital manuals in multiple languages.

- 7. What about after-sales support?

- 24/7 remote technician support, critical spare parts inventory, regular software updates, and optional annual on-site audits are standard among leading air filter making machine brands.

Quick Facts: Why Choose Anya's Filter Making Machines?

- 30+ YEARS of filter machinery design and production experience

- Exports to 24+ countries; trusted by major OEMs worldwide

- Fully complies with latest ISO, CE, FDA norms

- Reference clients: Johnson Controls, LG Electronics, Sinopec

Post time: Jul-29-2025