The Crucial Role of Fiberglass Media in Advanced Filtration Systems

In industrial and commercial filtration, the selection of an appropriate filter medium is paramount to operational efficiency, environmental compliance, and cost-effectiveness. Among the myriad options available, fiberglass media stands out as a high-performance solution, widely recognized for its superior filtration capabilities and durability. This material forms the backbone of critical air and liquid filtration systems across diverse sectors, ensuring cleaner air, purer fluids, and optimized process environments.

The demand for advanced filtration solutions continues to escalate, driven by increasingly stringent regulatory standards for air and water quality, coupled with the imperative for energy efficiency in industrial operations. As industries seek to minimize particulate emissions, protect sensitive equipment, and safeguard human health, the evolution of fiberglass media technology becomes a key enabler. This section delves into the intrinsic properties and market trends shaping the future of fiberglass filtration.

Industry Trends and Market Dynamics

The global market for filtration media, and specifically fiberglass filter media, is experiencing robust growth. Projections indicate a significant compound annual growth rate (CAGR), fueled by expanding industrialization, particularly in emerging economies, and heightened awareness regarding indoor air quality (IAQ) and industrial pollution control. Key trends include:

- Emphasis on Energy Efficiency: Manufacturers are developing fiberglass media with lower pressure drop characteristics, directly translating into reduced energy consumption for HVAC systems and industrial blowers. This directly addresses operational cost pressures for B2B clients.

- Advanced Composites: The integration of glass fibers with other synthetic materials or surface treatments to enhance specific properties like hydrophobic behavior, chemical resistance, or anti-microbial capabilities.

- Sustainability Initiatives: A growing focus on recyclable and environmentally friendly manufacturing processes for fiberglass filter cloth, aiming to minimize environmental impact throughout the product lifecycle.

- Smart Filtration Systems: Integration of sensors and IoT (Internet of Things) technologies with filtration systems to monitor filter performance in real-time, predict maintenance needs, and optimize filter replacement cycles, thereby enhancing the operational experience for end-users.

These trends underscore the evolving landscape where performance, sustainability, and intelligent monitoring converge to redefine filtration standards, with advanced glass fiber solutions at the forefront of innovation.

The Manufacturing Process of Fiberglass Media

The production of high-quality fiberglass media is a sophisticated process that demands precision engineering and rigorous quality control. This section outlines the key stages involved in transforming raw glass materials into advanced filtration media, highlighting the technical intricacies and quality benchmarks.

Materials and Composition

The primary raw material is high-purity glass, typically E-glass (electrical grade glass) or specific formulations optimized for filtration. These glasses are selected for their thermal stability, chemical inertness, and mechanical strength. Key additives include organic binders, which provide structural integrity to the non-woven mat, and sometimes fire retardants or water repellents depending on the application. The controlled selection of these materials ensures the final product's durability and performance in demanding environments.

Schematic Process Flow

- Glass Melting and Fiber Drawing: High-grade glass raw materials are melted in a furnace at extremely high temperatures (e.g., 1400-1600°C). Molten glass is then drawn through fine orifices (bushings) to produce continuous filaments with diameters typically ranging from 0.5 to 10 micrometers. The precise control over fiber diameter is critical for determining the media's filtration efficiency and pressure drop. This step demands highly controlled temperature and flow dynamics.

- Fiber Mat Formation (Wet-laid or Dry-laid):

- Wet-laid Process: Fibers are dispersed in a water-based slurry, then deposited onto a moving screen, similar to papermaking. This method produces highly uniform, thin mats with excellent pore distribution, suitable for high-efficiency applications like HEPA/ULPA filters.

- Dry-laid Process: Fibers are air-laid or carded to form a non-woven web. This process is generally used for thicker, lower-density media, often found in pre-filters. The choice of process impacts the media's density and filtration characteristics.

- Binder Impregnation: The formed glass fiber mat is then impregnated with an organic binder (e.g., acrylic resins, phenolic resins). The binder ensures fiber adhesion, provides structural stability, and enhances mechanical properties such as tensile strength and dimensional stability. The type and amount of binder are carefully calibrated.

- Curing and Drying: The impregnated mat passes through ovens where the binder is thermally cured. This step removes solvents and cross-links the binder, solidifying the media's structure and porosity. Precise temperature control is crucial to prevent degradation of the glass fibers or binder, ensuring optimal performance and service life.

- Calendering (Optional): For specific applications requiring high density, smoothness, or controlled thickness, the media may pass through heated rollers (calendering) to achieve desired characteristics. This can fine-tune properties like air permeability and strength.

- Slitting and Finishing: The cured media is then cut (slit) into specified widths and rolled onto cores, ready for further processing into finished filter products, such as pockets, pleats, or rolls. Strict dimensional tolerances are maintained for seamless integration into filter frames.

Testing Standards and Quality Assurance

Manufacturing adheres strictly to international testing standards to ensure consistent quality and performance. Key standards include:

- ISO 16890: Specifies a new classification system for air filters based on their efficiency for different particulate matter (PM) fractions (PM1, PM2.5, PM10). This is crucial for evaluating indoor air quality and ensuring effective particle capture.

- EN 779 (now superseded by ISO 16890): Previous European standard for general ventilation filters, still referenced for existing systems and providing a framework for efficiency assessment.

- ASHRAE 52.2: American standard for testing general ventilation air-cleaning devices for removal efficiency by particle size. MERV (Minimum Efficiency Reporting Value) ratings are derived from this standard, providing a comparative measure of filter performance.

- UL 900: Standard for Air Filter Units, primarily concerning flammability and fire resistance, a critical safety aspect for fiberglass media in HVAC systems, ensuring compliance with fire safety regulations.

Stringent in-house quality control procedures, including inspections for basis weight, thickness, air permeability, tensile strength, and efficiency, are conducted at every stage to meet or exceed these benchmarks, guaranteeing product reliability and a long service life.

Figure 1: Illustration of fiberglass filter media manufacturing process steps, emphasizing precision and quality.

Technical Specifications and Performance Parameters of Fiberglass Media

Understanding the technical specifications of fiberglass media is crucial for engineers and procurement professionals to select the optimal solution for specific industrial and commercial applications. These parameters directly influence filter performance, operational costs, and overall system efficiency.

Key Performance Indicators (KPIs)

- Filtration Efficiency: Measured by MERV (ASHRAE 52.2) or ISO ePM (ISO 16890) ratings, indicating the percentage of particulate matter captured at various sizes (e.g., ePM1, ePM2.5, ePM10). High-efficiency fiberglass media can achieve MERV 13-16 ratings or ISO ePM1 > 80%, crucial for clean air applications.

- Initial Pressure Drop (ΔP): The resistance to airflow exerted by the clean filter medium. Lower initial pressure drop translates directly to reduced energy consumption by fans and blowers. Fiberglass media excels in offering low initial ΔP while maintaining high efficiency, a key factor in energy saving.

- Dust Holding Capacity (DHC): The total amount of dust a filter can hold before reaching its terminal pressure drop or requiring replacement. High DHC extends filter service life, reducing maintenance frequency and associated operational costs.

- Temperature Resistance: The maximum continuous operating temperature the media can withstand without degrading. Fiberglass media typically offers excellent thermal stability, often up to 250°C, and some specialized types can handle even higher, making it suitable for hot industrial gases.

- Chemical Resistance: The ability of the media to withstand exposure to various chemicals, acids, and alkalis, crucial for applications in petrochemical or chemical processing industries where aggressive substances are present.

- Basis Weight & Thickness: These physical properties influence mechanical strength, stiffness, and filtration characteristics, determining the filter's robustness and efficiency.

Typical Product Specification Table: Fiberglass Pocket Filter Media

Below are representative specifications for Fiberglass Pocket Filter Media, a common application of fiberglass filter media, demonstrating its robust capabilities:

| Parameter | Specification Range | Testing Standard |

|---|---|---|

| Filter Class (ISO 16890) | ISO ePM10 > 50% to ISO ePM1 > 80% | ISO 16890 |

| Filter Class (ASHRAE) | MERV 10 to MERV 15 | ASHRAE 52.2 |

| Nominal Airflow (m³/h/m²) | 1500 - 3600 | Manufacturer Specific |

| Initial Pressure Drop (Pa) @ Nominal Airflow | 40 - 80 | ISO 16890 / ASHRAE 52.2 |

| Recommended Final Pressure Drop (Pa) | 250 - 450 | Manufacturer Specific |

| Dust Holding Capacity (g/m²) | 250 - 600 | ISO 16890 / ASHRAE 52.2 |

| Max. Operating Temperature (°C) | 120 - 250 | Product Data Sheet |

| Moisture Resistance | Relative humidity up to 100% (non-condensing) | Product Data Sheet |

| Fire Retardancy | UL 900 Class 2 | UL 900 |

These specifications underscore the versatility and high performance inherent in quality fiberglass filter cloth, making it a preferred choice for demanding environments where consistent filtration and durability are non-negotiable.

Technical Advantages of Fiberglass Media

The intrinsic properties of fiberglass media confer a distinct set of technical advantages, making it an indispensable material in a broad spectrum of filtration applications where performance, durability, and cost-efficiency are critical.

Superior Filtration Efficiency and Dust Holding Capacity

- High Efficiency: The fine, randomly distributed glass fibers create a tortuous path for air or fluid, trapping a high percentage of fine particulates. This ensures compliance with strict air quality standards and protection for downstream equipment, minimizing contamination risks.

- Excellent Dust Holding Capacity: The open, progressive density structure of fiberglass allows for deep particle loading throughout the filter depth, significantly extending the service life compared to surface-loading media. This reduces the frequency of filter changes and associated labor and disposal costs.

Energy Saving through Low Pressure Drop

One of the most significant advantages for B2B applications is the inherent low initial pressure drop of fiberglass filters. The optimized fiber structure minimizes resistance to airflow, leading to lower energy consumption by HVAC fans and industrial blowers. Over the filter's lifetime, this translates into substantial operational cost savings, contributing directly to a lower total cost of ownership (TCO) and improved sustainability profiles for businesses.

Exceptional Thermal and Chemical Resistance

- Thermal Stability: Fiberglass media can operate efficiently in high-temperature environments (e.g., up to 250°C continuously, and higher for short periods) that would degrade synthetic or organic media. This makes it ideal for industrial processes involving hot gases or air streams in various manufacturing stages.

- Corrosion Resistance: The inert nature of glass fibers provides excellent resistance to a wide range of corrosive chemicals, including acids and alkalis, making it suitable for demanding applications in chemical, petrochemical, and pharmaceutical industries where chemical compatibility is critical.

Durability and Mechanical Stability

The robust mechanical properties of glass fibers, combined with advanced binder systems, result in media that is resistant to tearing, shedding, and compression, even under fluctuating airflows or in environments with high humidity. This ensures consistent performance throughout the filter's operational life, minimizing the risk of media failure and subsequent contamination.

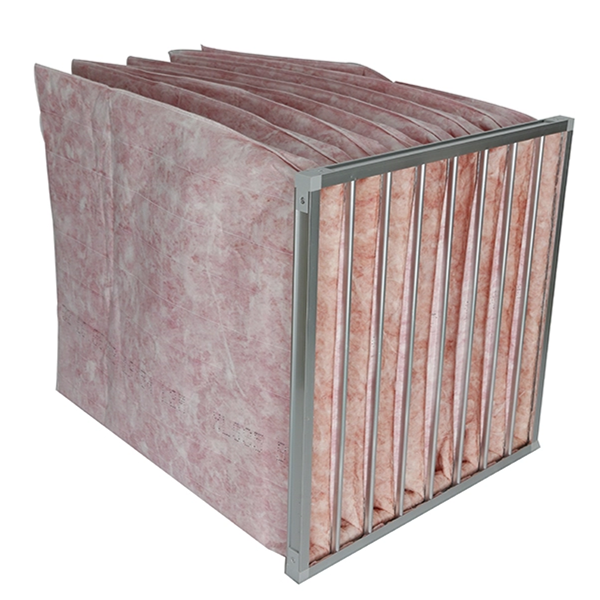

Figure 2: Fiberglass filter media demonstrating high dust holding capacity in a pocket filter configuration, optimized for extended service life.

Application Scenarios and Target Industries

The versatility and robust performance characteristics of fiberglass media make it suitable for a vast array of filtration applications across numerous heavy and light industries. Its ability to handle challenging conditions, from high temperatures to corrosive atmospheres, ensures reliable operation where other materials would fail.

HVAC Systems (Commercial & Industrial)

Fiberglass filter media is a cornerstone in modern HVAC systems, from large commercial buildings to specialized industrial ventilation. It's extensively used in:

- Commercial Buildings: Hospitals, offices, schools, and shopping centers rely on fiberglass filters for effective particulate removal, enhancing indoor air quality (IAQ) and protecting sensitive HVAC coils from dust buildup. This leads to healthier environments and reduced maintenance.

- Cleanrooms: In pharmaceutical manufacturing, microelectronics, and biotechnology, ultra-fine fiberglass media is essential for HEPA and ULPA filters, ensuring particulate-free environments critical for product integrity and process control, meeting stringent ISO standards.

- Paint Booths: Fiberglass filter cloth is widely employed in automotive and industrial paint spray booths as both pre-filters and final filters, efficiently capturing overspray and ensuring a clean finish, preventing defects and rework.

Petrochemical and Chemical Processing

The chemical inertness and high-temperature resistance of glass fiber filtration media are invaluable in these demanding sectors:

- Gas Turbines & Compressors: Used for intake air filtration, protecting delicate turbine blades and compressor components from abrasive dust and contaminants, thereby extending equipment lifespan and maintaining efficiency in power generation and process air.

- Process Air Filtration: Filtering air in chemical reactors, dryer systems, and other process equipment where high temperatures or corrosive gases are present, ensuring product purity and process reliability.

Power Generation

Coal-fired, gas-fired, and nuclear power plants utilize glass fiber filtration for various applications, including intake air for large machinery, ensuring optimal combustion and protecting critical components, as well as environmental emission control to comply with stringent regulations.

Metallurgy and Foundries

Managing dust and fumes in high-temperature metal processing environments requires robust filter media. Fiberglass filters are ideal for capturing particulate matter from furnaces, smelting operations, and casting processes, contributing to worker safety, maintaining air quality, and ensuring emission compliance.

Water Supply & Drainage (Specific Applications)

While often associated with air filtration, specialized coarse fiberglass filter media can be adapted for certain liquid filtration pre-treatment stages where chemical resistance and structural integrity are prioritized, acting as a robust pre-filter to protect finer downstream filtration stages. For instance, in industrial wastewater treatment, robust media is needed to handle high solids loading and harsh chemical environments, demonstrating the material's broad utility.

Figure 3: Fiberglass filter media application in an industrial ventilation system, demonstrating robust performance in challenging environments.

Vendor Comparison and Customized Solutions

Selecting the right supplier for fiberglass media is as critical as choosing the media itself. B2B decision-makers must consider not only product specifications but also manufacturing capabilities, quality assurance, and the ability to provide tailored solutions. This section aids in making informed decisions by outlining key differentiators.

Key Considerations for Vendor Selection

- Certifications and Compliance: Verify ISO 9001 for quality management, and product-specific certifications like UL 900. Adherence to standards like ISO 16890 or ASHRAE 52.2 is non-negotiable for ensuring product reliability and regulatory compliance.

- Manufacturing Expertise: Assess the vendor's experience in glass fiber technology, binder chemistry, and process control. A long-standing history often indicates deep industry knowledge and consistent product quality.

- Research and Development (R&D): A commitment to R&D ensures access to innovative media types with improved efficiency, lower pressure drop, or enhanced durability, offering a competitive edge.

- Supply Chain Reliability: The ability to consistently deliver high-quality products on schedule is vital for maintaining uninterrupted operations and minimizing costly downtime.

- Technical Support: Access to expert technical assistance for product selection, system optimization, and troubleshooting can significantly add value, ensuring optimal system performance.

Vendor Comparison: Key Differentiators

| Feature/Criterion | Tier 1 Supplier (e.g., Anyafiltermedia) | Standard Supplier |

|---|---|---|

| Product Range | Comprehensive, including specialized media for HEPA/ULPA, high temp, chemical resistance. | Standard efficiency filters, limited specialization, fewer advanced options. |

| Quality Certifications | ISO 9001:2015, UL 900, audited to international filtration standards. | Basic ISO, possibly no specific product certifications, less rigorous auditing. |

| Customization Capabilities | Extensive: custom dimensions, specific basis weights, proprietary binder formulations, progressive density layering. | Limited to standard cuts and basic material modifications, less flexibility. |

| Technical Support | Dedicated application engineers, performance modeling, on-site consultation, robust after-sales. | Basic product data sheets, limited post-sale support, often reactive. |

| Lead Time for Custom Orders | Competitive, optimized for project schedules (e.g., 4-6 weeks for specialized runs). | Often longer, less flexible, may disrupt project timelines. |

Customized Solutions

Leading manufacturers understand that off-the-shelf solutions may not always meet the unique demands of specific industrial applications. Customization capabilities for glass fiber filtration media include:

- Tailored Dimensions and Thickness: Producing media in non-standard widths, lengths, or thicknesses to perfectly fit existing equipment or new designs, minimizing waste and optimizing fit.

- Specific Filtration Efficiencies: Engineering media to achieve precise MERV or ISO ePM ratings, often through adjusting fiber diameter, density, and binder content for specialized applications.

- Enhanced Chemical or Thermal Resistance: Incorporating specialized glass formulations or binder systems to withstand extreme temperatures (e.g., up to 500°C short-term) or aggressive chemical environments.

- Surface Treatments: Applying hydrophobic coatings for moisture resistance or anti-microbial treatments for sensitive environments like hospitals or food processing plants.

- Progressive Density Layering: Designing multi-layer media where fiber density gradually increases through the filter depth, optimizing dust holding capacity and ensuring efficient capture of various particle sizes.

These customized solutions ensure that clients receive a filtration product precisely engineered for their unique challenges, maximizing performance, compliance, and return on investment.

Application Case Studies and Customer Experience

Real-world application case studies vividly demonstrate the impact and effectiveness of advanced filtration media. These examples highlight how specific challenges were met, showcasing the practical advantages and the positive experiences of our clients.

Case Study 1: Energy Savings in a Large Commercial HVAC System

Client: A major international airport facility.

Challenge: The airport's existing HVAC system utilized synthetic media filters with relatively high initial pressure drop, leading to significant energy consumption for its extensive ventilation network. They sought to reduce operational costs and improve their environmental footprint without compromising air quality (MERV 13 equivalent required).

Solution: After a comprehensive analysis, we recommended replacing their existing pre-filters and main filters with advanced pocket filters utilizing low-pressure-drop fiberglass filter media. These filters were engineered to maintain MERV 13 efficiency while offering a 15% lower initial pressure drop, significantly reducing the load on the HVAC blowers.

Results: Over an 18-month period, the airport reported a verifiable 12% reduction in energy consumption directly attributable to the improved filtration system, translating to annual savings of over $150,000 in electricity costs. Air quality readings remained consistently high, meeting or exceeding regulatory standards. The extended dust holding capacity of the fiberglass media also reduced filter change-out frequency by 20%, cutting labor and disposal costs, further enhancing operational efficiency.

Case Study 2: Corrosion Protection in a Petrochemical Plant

Client: A leading chemical manufacturer producing specialized polymers.

Challenge: The plant's air intake systems for sensitive processing equipment were constantly exposed to airborne corrosive agents and fine particulate matter, leading to frequent equipment malfunctions, increased maintenance, and premature failure of traditional filter media. High temperatures within the process also exacerbated the issue, requiring a robust solution.

Solution: We developed a customized fiberglass filter cloth solution with enhanced chemical resistance properties and high-temperature binders. These media were then integrated into rigid box filters designed for the plant's specific operational environment, ensuring resistance to aggressive chemicals and sustained thermal performance.

Results: The specialized fiberglass filters demonstrated exceptional resistance to the plant's corrosive atmosphere, significantly extending filter life from 3 months to over 9 months. This drastically reduced maintenance downtime, part replacement costs for downstream equipment, and ensured continuous, uncompromised process operations. The client noted a 70% decrease in air quality related equipment failures post-implementation, a clear testament to the media's durability.

Customer Feedback

"Switching to their fiberglass media for our cleanroom HVAC was a game-changer. We achieved ISO Class 7 certification with greater consistency and noticed a marked improvement in the stability of our particle counts. The technical support throughout the transition was exemplary, truly a partnership."

– Production Manager, Pharmaceutical Industry.

"The customized fiberglass filters provided for our power plant's intake have proven incredibly durable in harsh conditions, reducing our filter replacement frequency by half. This directly translates to less downtime and significant cost savings, reinforcing our operational efficiency."

– Operations Director, Thermal Power Generation.

Figure 4: Detailed view of a fiberglass pocket filter, ready for installation, highlighting design and material integrity.

Commitment to Trust and Support

Building lasting partnerships in the B2B sector hinges on transparency, reliability, and robust support. We are committed to providing not only superior filtration media but also comprehensive services that instill confidence and ensure smooth operations for our clients.

Frequently Asked Questions (FAQ)

Q: What is the typical service life of fiberglass media filters?

A: Service life varies significantly based on operating conditions (e.g., dust loading, airflow, temperature) and the specific application. However, high-quality fiberglass pocket filters typically last 6 to 18 months in standard HVAC applications before reaching their recommended final pressure drop. In industrial settings with higher dust loads, pre-filters might require more frequent replacement (e.g., 3-6 months), while fine filters can last longer, all depending on environmental factors.

Q: Is fiberglass media safe for all environments?

A: Yes, fiberglass media is generally safe and widely used. The glass fibers are non-respirable (larger than 3 microns) and are securely bound within the filter matrix, preventing shedding. Products adhere to strict safety standards (e.g., UL 900 for flammability), ensuring safe operation in appropriate applications and minimizing health risks.

Q: Can fiberglass filters be recycled?

A: While the glass fibers themselves are technically recyclable, the presence of binders and captured contaminants often makes recycling post-consumer fiberglass filters challenging and costly. Efforts are ongoing in the industry to develop more economically viable recycling pathways and sustainable disposal methods. We encourage clients to check local regulations and consider specialized waste management services for industrial filter disposal.

Lead Time and Fulfillment

We maintain efficient production lines and robust inventory management to ensure timely fulfillment. Standard glass fiber media rolls typically have a lead time of 1-2 weeks. For customized orders or large-volume projects, lead times are estimated between 4-6 weeks, depending on complexity and material availability. Expedited options are available upon request for urgent requirements, ensuring minimal disruption to client operations.

Warranty Commitments

All our fiberglass filter media products are backed by a comprehensive warranty against manufacturing defects. The specific terms and duration (e.g., 12-24 months from the date of purchase) are outlined in our product documentation, providing assurance of quality and performance against specified parameters and industry standards.

Dedicated Customer Support and After-Sales Service

Our relationship with clients extends beyond the sale. We provide:

- Technical Consultation: Expert engineers are available to assist with product selection, system design, and optimization for maximum filtration efficiency and cost savings, tailored to your specific needs.

- Performance Monitoring Guidance: Advice on establishing effective monitoring protocols to track filter performance and predict maintenance needs, enabling proactive management.

- Responsive Troubleshooting: Prompt assistance to resolve any performance issues or address technical queries post-installation, minimizing downtime and ensuring continuous operation.

- Training: Providing training materials or sessions for client personnel on proper handling, installation, and maintenance of fiberglass filter media, empowering your team.

Conclusion: The Enduring Value of Fiberglass Media

As industries worldwide navigate increasingly complex challenges related to air quality, operational efficiency, and environmental sustainability, the role of advanced filtration media becomes ever more critical. Fiberglass media, with its unparalleled combination of high efficiency, low pressure drop, thermal stability, and chemical resistance, continues to prove itself as a foundational component in high-performance filtration systems. Its adaptability, coupled with ongoing innovations in manufacturing and application, ensures its sustained relevance across diverse industrial and commercial landscapes.

Investing in high-quality fiberglass filtration solutions is not merely a compliance measure; it is a strategic decision that drives significant returns through reduced energy consumption, extended equipment lifespan, lower maintenance costs, and improved process integrity. As a trusted partner, we are dedicated to advancing filtration technology and providing tailored solutions that meet the evolving demands of our global clientele, ensuring superior performance and long-term value.

References

- ISO 16890. (2016). Air filters for general ventilation - Part 1: Technical specifications, requirements and classification system based upon particulate matter efficiency (ePM). International Organization for Standardization.

- ASHRAE Standard 52.2-2017. (2017). Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size. ASHRAE.

- UL 900. (2015). Standard for Air Filter Units. Underwriters Laboratories.

- European Commission. (2009). Directive 2009/125/EC of the European Parliament and of the Council of 21 October 2009 establishing a framework for the setting of ecodesign requirements for energy-related products. Official Journal of the European Union.

- Wang, P. (2012). Filtration Efficiency and Pressure Drop of Fibrous Filters: A Review. Separation and Purification Reviews, 41(3), 179-225.

Post time: Aug-31-2025