In modern industrial operations, effective particulate matter control is not merely a regulatory requirement; it is a cornerstone of operational efficiency, worker safety, and environmental stewardship. At the heart of any robust dust collection system lies the **dust collector filter media**, the unsung hero responsible for separating microscopic dust particles from the air stream. Understanding the intricate details of this critical component, from its manufacturing process to its application across diverse industries, is paramount for achieving optimal performance and compliance.

This comprehensive guide explores the multifaceted world of **dust collector filter media**, delving into industry trends, technical specifications, diverse applications, and the distinct advantages offered by high-quality filtration solutions. We will provide insights into choosing the right manufacturer, explore custom solutions, and present real-world application examples, all while upholding the highest standards of expertise, experience, authoritativeness, and trustworthiness (EEAT).

Industry Trends and the Evolution of **Dust Collector Filter Media**

The landscape of industrial air filtration is continuously evolving, driven by stringent environmental regulations, advancements in material science, and increasing demands for energy efficiency. The market for **dust collector filter media** is experiencing significant growth, projected to reach over USD 14 billion by 2028, with a compound annual growth rate (CAGR) of approximately 5-7% from 2023 to 2028. This growth is fueled by:

- Stricter Emission Standards: Governments worldwide are implementing more rigorous air quality standards (e.g., EPA, EU directives), forcing industries to invest in more efficient filtration technologies and materials.

- Focus on Energy Efficiency: High-performance **dust filter media** that offer lower pressure drop can significantly reduce the energy consumption of dust collection systems, leading to substantial operational cost savings.

- Emergence of Advanced Materials: Research and development are yielding new synthetic fibers and membrane technologies (e.g., PTFE membranes, Nano-fiber coatings) that enhance filtration efficiency, durability, and chemical resistance. These innovations allow for superior particle capture, even for sub-micron particles, and extended filter lifespan.

- Industry 4.0 Integration: Smart filtration systems incorporating sensors for real-time monitoring of pressure drop, filter integrity, and emission levels are becoming more prevalent, necessitating filter media that can integrate seamlessly into these advanced setups.

- Circular Economy Principles: A growing emphasis on sustainability is driving demand for filter media that are durable, washable, or recyclable, reducing waste and promoting resource efficiency.

These trends underscore the importance of selecting advanced **dust collector filter media** that not only meet current needs but are also future-proofed against evolving regulatory and operational challenges.

Understanding the Technical Parameters of **Dust Collector Filter Media**

Choosing the correct **dust collector filter media** requires a thorough understanding of its technical specifications. These parameters dictate the media's performance characteristics, including filtration efficiency, lifespan, and suitability for specific applications. Key parameters include:

- Filtration Efficiency: This is the most crucial parameter, indicating the percentage of particles removed from the air. It's often measured at different particle sizes (e.g., 0.3 micron, 1.0 micron, 2.5 micron). Standards like ISO 16890 and ASHRAE 52.2 (MERV rating) categorize filter efficiency.

- MERV (Minimum Efficiency Reporting Value): A rating from 1 to 20; higher MERV values indicate greater efficiency in capturing smaller particles. Industrial **dust filter media** often have MERV ratings ranging from 10 to 16, or even higher for HEPA/ULPA applications.

- PM2.5/PM10 Efficiency (ISO 16890): Defines efficiency for specific particulate matter sizes relevant to air quality.

- Air Permeability (Airflow Resistance): Measured in m³/m²/min or CFM/ft², this indicates how easily air can pass through the media. Lower permeability means higher pressure drop and more energy consumption but often higher filtration efficiency. An optimal balance is critical.

- Tensile Strength: The maximum stress the filter media can withstand before breaking, crucial for durability, especially in pulse-jet cleaning systems. Measured in N/5cm or lbs/inch.

- Burst Strength: The pressure required to burst the fabric, indicating its resistance to sudden pressure changes.

- Weight (Basis Weight): Measured in g/m² or oz/yd², indicates the density of the material, influencing strength, thickness, and dust holding capacity.

- Thickness: Affects filtration efficiency and dust holding capacity. Measured in mm or mils.

- Temperature Resistance: The maximum continuous operating temperature the media can withstand without degradation. Different fibers have different temperature limits (e.g., Polyester up to 135°C, Aramid up to 200°C, PTFE up to 260°C).

- Chemical Resistance: The media's ability to resist degradation from acids, alkalis, and various industrial chemicals present in the gas stream.

- Surface Treatment/Finishes: Applied coatings or treatments to enhance properties like hydrophobicity (water repellency), oleophobicity (oil repellency), anti-static properties, or improved dust cake release (e.g., PTFE membrane lamination).

- Dust Holding Capacity (DHC): The amount of dust a filter can hold before its pressure drop becomes too high, requiring cleaning or replacement. Higher DHC translates to longer service intervals.

Typical Parameters for **Dust Collector Filter Media**

Below is a table illustrating common parameters for various types of **dust filter media**, providing a comparative overview to aid in selection:

| Parameter | Polyester (PET) Needle Felt | Polypropylene (PP) Needle Felt | Aramid (Nomex) Needle Felt | PTFE Membrane Laminated PET | Fiberglass Woven Fabric |

|---|---|---|---|---|---|

| Typical Weight (g/m²) | 450 - 600 | 450 - 550 | 500 - 650 | 500 - 600 | 800 - 1000 |

| Thickness (mm) | 1.8 - 2.5 | 1.8 - 2.3 | 2.0 - 2.8 | 2.0 - 2.6 | 1.5 - 2.0 |

| Max. Temp (°C) | 130 - 150 | 90 - 100 | 190 - 200 | 130 - 150 (with PET base) | 260 - 280 |

| Air Permeability (m³/m²/min @ 200Pa) | 10 - 20 | 15 - 25 | 8 - 18 | 2 - 8 (very low) | 5 - 12 |

| Filtration Efficiency (ePM10) | 80-90% | 75-85% | 90-95% | >99.9% (surface filtration) | 98-99% |

| Chemical Resistance | Good (acids, weak alkalis) | Excellent (acids, alkalis) | Good (acids, fair alkalis) | Excellent (broad spectrum) | Excellent (strong acids) |

| Abrasion Resistance | Good | Fair | Excellent | Good | Fair |

| Typical Lifespan (Years) | 1-3 | 1-2 | 3-5 | 2-4 | 3-5 |

Manufacturing Process of **Dust Collector Filter Media**: From Fiber to Filtration Excellence

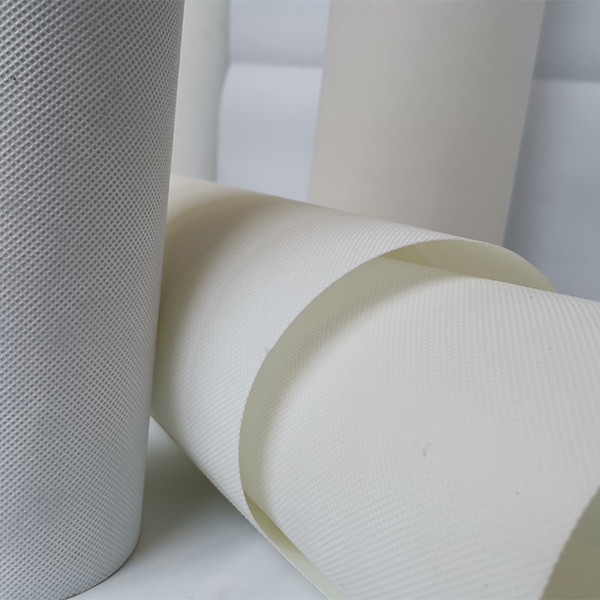

The creation of high-performance **dust collector filter media** is a complex process that combines advanced material science with precise engineering. The goal is to produce a medium with a carefully controlled pore structure, optimal strength, and specific chemical and thermal resistances. While variations exist, a typical process for needle-punched non-woven felt, a common type of **dust collector filter media**, involves the following key stages:

Conceptual Process Flow for Needle-Punched Filter Media:

1. Fiber Selection & Preparation: Selection of raw fibers (e.g., Polyester, Polypropylene, Aramid, P84, PPS, PTFE) based on application requirements (temperature, chemical resistance, desired efficiency). Fibers are opened and blended to achieve uniform composition and properties.

↓

2. Carding: Fibers are fed into a carding machine, which disentangles them and aligns them into a thin, uniform web or batt. This web forms the foundation of the filter media.

↓

3. Web Laying: Multiple webs are layered on top of each other to achieve the desired thickness and weight, creating a multi-layered fiber mat.

↓

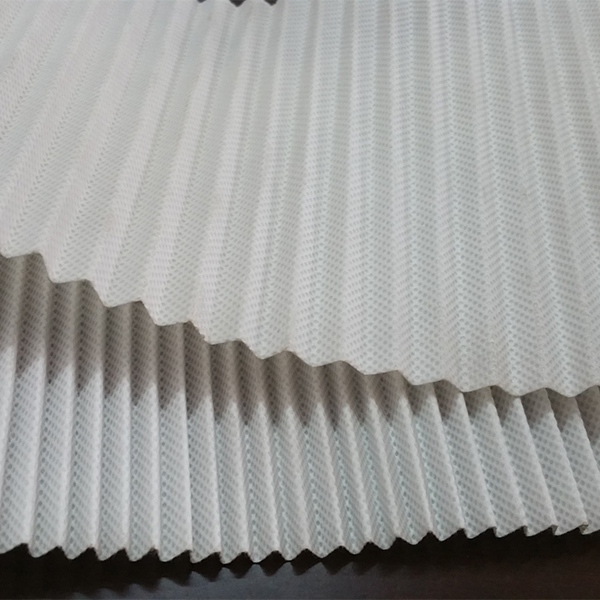

4. Needle Punching: The layered web passes through a needle loom. Barbed needles repeatedly penetrate and withdraw from the web, mechanically interlocking the fibers and consolidating the material into a strong, cohesive felt. The density and pore structure are controlled by needle type, density, and stroke depth.

↓

5. Heat Setting (Thermo-bonding): The needle-punched felt is subjected to precise heat treatment. This process stabilizes the fabric, shrinks it slightly to increase density, and enhances its dimensional stability and strength, preventing fiber shedding.

↓

6. Surface Finishing & Treatment:

- Singing/Glazing: Passing the felt over a flame or hot plate to burn off surface fibers, creating a smoother surface for better dust cake release.

- Calendering: Passing the felt through heated rollers to compress and densify the surface, further enhancing dust release and reducing surface roughness.

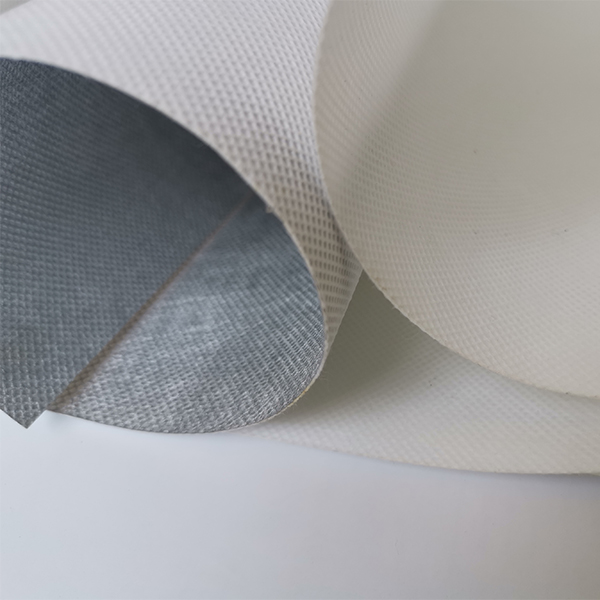

- Chemical/Membrane Coating: Application of various coatings (e.g., water/oil repellent treatments, anti-static treatments, or lamination with an expanded PTFE (ePTFE) membrane for surface filtration and very high efficiency).

↓

7. Slitting & Inspection: The finished filter media roll is precisely slit into desired widths and lengths. During this stage, rigorous quality control checks are performed for weight, thickness, air permeability, and visual defects.

↓

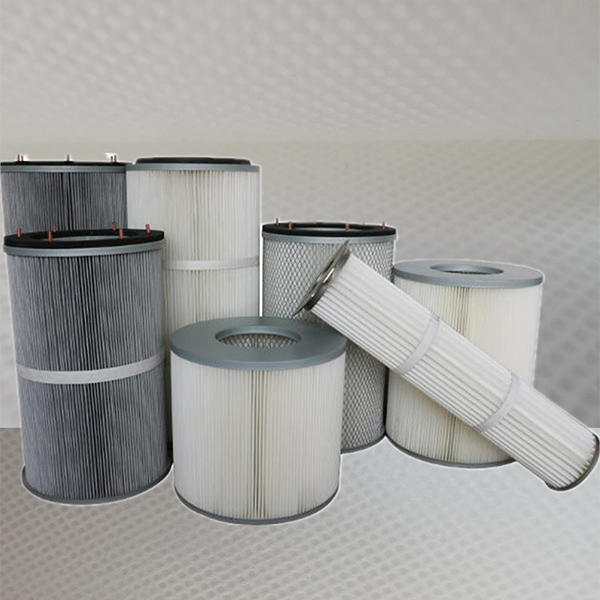

8. Final Product: Ready for fabrication into filter bags, cartridges, or panels.

Key Aspects in the Manufacturing of Dust Collector Filter Media:

- Material Composition: The choice of primary fibers is critical. Polyester (PET) is common for general industrial applications due to its versatility and cost-effectiveness. Polypropylene (PP) offers excellent acid and alkali resistance for specific chemical environments. Aramid (Nomex) is preferred for high-temperature applications. More specialized materials like PPS (Ryton), P84 (Polyimide), and PTFE (Teflon) are used for extreme temperatures, harsh chemicals, or specific dust characteristics. The blend of fibers, including support scrims (woven fabrics embedded within the felt for strength), significantly influences the final product's performance.

- Manufacturing Process Details:

- Needle Punching: This mechanical interlocking process is central to creating a stable felt. The type of needles, the depth of penetration, and the number of punches per unit area directly impact the felt's density, strength, and filtration characteristics (e.g., pore size distribution).

- Heat Setting: Precisely controlled temperature and tension during heat setting are vital for optimizing the media's dimensional stability and preventing shrinkage or deformation during operation.

- Surface Treatments: The application of surface finishes, such as a singed or glazed finish, prevents fiber shedding and improves the release of the dust cake, leading to more efficient cleaning and lower pressure drop. The lamination of an ePTFE membrane transforms depth filtration into surface filtration, drastically increasing efficiency (often >99.9% for sub-micron particles) and extending filter life in challenging applications.

- Quality Control & Testing Standards: Adherence to international standards is paramount to ensure consistent product quality and performance.

- ISO Standards: ISO 9001 (Quality Management System) ensures consistent manufacturing processes. ISO 16890 (Air Filter Efficiency) provides a global classification system for general ventilation filters, which principles are often adapted for industrial media.

- ASTM Standards: ASTM F778 (Standard Test Method for Gas-Stream Filter Performance) for measuring dust loading capacity and efficiency. ASTM D6810 (Standard Test Method for Determining the Cleanability of Baghouse Filter Media). ASTM D461 (for weight and thickness).

- ANSI Standards: Relevant for specific application requirements or system integration.

- In-house Testing: Reputable manufacturers conduct extensive in-house testing for burst strength, tensile strength, air permeability, temperature resistance, and chemical compatibility to ensure product meets specifications.

- Usage Lifespan: The lifespan of **dust collector filter media** varies significantly based on material, application, operating conditions (temperature, humidity, chemical exposure, abrasive dust), and the effectiveness of the cleaning system. A well-chosen filter media can last from 1 to 5 years, with some specialized materials or applications extending beyond that. Proper maintenance and system optimization are crucial for maximizing lifespan.

Diverse Application Scenarios of **Dust Collector Filter Media**

The versatility of **dust collector filter media** allows its deployment across an incredibly diverse range of industries, each with unique challenges related to particulate matter, temperature, and chemical composition. From heavy industry to sensitive manufacturing environments, effective filtration is non-negotiable.

Applicable Industries:

- Cement & Concrete Industry: Handling abrasive and fine cement dust in kiln, clinker cooler, and cement mill applications. Requires media with excellent abrasion resistance and good dust cake release.

- Metallurgy & Steel Industry: Managing high temperatures and often abrasive dust from electric arc furnaces, blast furnaces, and foundries. Aramid, PPS, P84, and Fiberglass media are common here.

- Power Generation (Coal-fired Power Plants): Critical for capturing fly ash and other combustion byproducts to meet stringent emission regulations. Often involves high temperatures and corrosive gases, necessitating specialized media like Fiberglass or PTFE.

- Chemical Processing: Dealing with corrosive gases and various dust types, including sticky or hygroscopic particles. Media must have excellent chemical resistance (e.g., PP, PTFE, PPS).

- Pharmaceutical & Food Processing: Demands for high purity and prevention of cross-contamination. Requires filter media that are often FDA-compliant, easy to clean, and offer very high efficiency to capture fine powders.

- Woodworking & Furniture Manufacturing: Capturing wood dust and chips, which can be combustible. Media should have good abrasion resistance and anti-static properties.

- Mining & Quarrying: Handling large volumes of abrasive mineral dust. Robust, high-strength media with good abrasion resistance is essential.

- Waste Incineration: Operating in high-temperature, corrosive environments with fine, often sticky ash. PTFE or Fiberglass media are commonly used.

- Plastics & Rubber Processing: Managing fine plastic powders and fumes.

- Abrasive Blasting & Sanding: Capturing fine abrasive particles to maintain clean working environments.

Product Advantages in Typical Application Scenarios:

- Energy Efficiency: High-permeability media or media with advanced surface treatments (e.g., PTFE membrane) facilitate better dust cake release. This reduces the frequency of pulse cleaning, maintaining a lower average pressure drop across the filter bags. A lower pressure drop directly translates to reduced energy consumption by the fan motor, offering significant operational cost savings, especially in large-scale operations. For instance, a 2-inch WC reduction in pressure drop can lead to 10-15% energy savings in a typical dust collector.

- Extended Lifespan & Reduced Maintenance:

- Abrasion Resistance: In industries like cement or mining, abrasive dust can rapidly wear down filter media. Specially treated polyester or Aramid media offer enhanced abrasion resistance, significantly extending filter life.

- Chemical Resistance: In chemical plants, corrosive gases can degrade standard media. Polypropylene or PTFE-based media provide superior chemical inertness, ensuring integrity and longevity in harsh environments.

- Temperature Stability: For high-temperature applications (e.g., metallurgy, power plants), media like Aramid or Fiberglass maintain structural integrity and filtration efficiency, preventing premature failure and costly downtime.

- Superior Filtration Performance:

- Sub-micron Particle Capture: PTFE membrane laminated media, such as that offered by ANYA FILTER MEDIA, provides surface filtration. This means dust particles are captured on the surface of the membrane rather than embedding within the filter's depth. This results in efficiencies often exceeding 99.99% for PM2.5 and even PM1.0 particles, crucial for meeting the most stringent emission limits and protecting worker health.

- Consistent Efficiency: Surface filtration also ensures more consistent efficiency over the filter's life, as the pore structure remains stable.

- Corrosion Resistance: Beyond chemical resistance, certain applications involve highly corrosive elements (e.g., acid gases). Media like those made from fiberglass with acid-resistant finishes or pure PTFE are engineered to withstand such aggressive environments, preventing material degradation and ensuring continuous operation. This prevents system downtime and costly replacements.

Selecting the Right Manufacturer and Tailoring Custom Solutions

The performance of your dust collection system heavily relies on the quality of its **dust collector filter media**, which in turn depends on the capabilities of your chosen manufacturer. It’s not just about buying a product; it’s about partnering with a specialist who understands your specific challenges and can deliver tailored solutions.

Key Considerations for Manufacturer Comparison:

- Expertise and R&D Capabilities: Look for manufacturers with a deep understanding of filtration science, material engineering, and dust collection systems. A strong R&D department indicates a commitment to innovation and the ability to develop advanced **dust filter media** for emerging needs.

- Quality Control and Certifications: A reputable manufacturer will adhere to stringent quality control processes throughout their production, from raw material sourcing to final product inspection. Certifications like ISO 9001 (Quality Management System) are indicators of a commitment to quality. Ask for specific product performance certifications (e.g., efficiency ratings, material compliance).

- Customization Capabilities: Not all applications are standard. A top-tier manufacturer should offer a wide range of materials, coatings, finishes, and the ability to produce **dust collector filter media** in various sizes and configurations (rolls, finished bags, cartridges) to meet unique requirements. This includes custom treatments for specific chemical, temperature, or abrasive conditions.

- Technical Support and After-Sales Service: Comprehensive technical support, including application engineering assistance, troubleshooting, and post-installation support, is crucial. This ensures you select the optimal media and can resolve any issues efficiently.

- Industry Experience and Track Record: A manufacturer with decades of experience and a strong track record of successful projects in your specific industry demonstrates proven reliability and a deep understanding of industry-specific challenges.

- Supply Chain Reliability: Ensure the manufacturer has a robust supply chain to guarantee timely delivery and consistent availability, especially for critical operations.

Customization: The Power of Tailored **Dust Collector Filter Media** Solutions

Generic filter media often result in suboptimal performance, shorter lifespans, and higher operational costs. Custom-engineered **dust filter media** offers a strategic advantage by precisely matching the filter's properties to the unique characteristics of your dust, gas stream, and operating conditions. At Anyafiltermedia.com, we emphasize a consultative approach to develop bespoke filtration solutions:

- Material Selection: Based on gas temperature, chemical composition (acidity/alkalinity), and moisture content, we can recommend and supply the most suitable fiber type (e.g., Polyester for general use, PPS for hydrolysis resistance, P84 for high temperature and chemical resistance, PTFE for extreme conditions and high efficiency).

- Surface Treatments: For sticky, hygroscopic, or oily dusts, we can apply specific finishes such as oleophobic/hydrophobic treatments, anti-static coatings, or PTFE membrane laminations. A PTFE membrane is particularly transformative, converting depth filtration into surface filtration for superior particle release and extremely high collection efficiency, significantly extending filter life and reducing system pressure drop.

- Fabric Construction: Adjustments to felt density, thickness, and reinforcement scrims can optimize mechanical strength, abrasion resistance, and dust holding capacity for heavy dust loads or abrasive environments.

- Bag/Cartridge Design: While focusing on media, a comprehensive solution also considers the final form, ensuring the media's properties are optimized for bag/cartridge dimensions, pleating, and cleaning mechanisms.

Our commitment to custom solutions ensures that clients receive not just a product, but a precision-engineered component that maximizes the efficiency, longevity, and cost-effectiveness of their dust collection system.

Application Cases and Customer Success Stories

The real-world impact of high-quality **dust collector filter media** is best illustrated through successful application cases. These examples highlight how optimal media selection translates into tangible benefits for various industries.

Case Study 1: Cement Plant Emissions Reduction

Challenge: A large cement production facility struggled to meet new, stricter PM2.5 emission limits from its clinker cooler and cement mill baghouses. Existing polyester media resulted in frequent bag replacements due to abrasion and inadequate sub-micron particle capture.

Solution: After a thorough analysis of dust characteristics (abrasive, high temperature spikes) and gas stream composition, the plant upgraded its baghouse filters to a high-performance Aramid needle felt with a reinforced scrim and a specialized surface finish for improved abrasion resistance. For the most critical points, a portion of the system was upgraded to **dust collector filter media** with an ePTFE membrane laminate.

Result: Within six months, the plant reported a consistent 99.9% reduction in PM2.5 emissions, comfortably meeting the new regulations. Filter lifespan increased by over 50%, significantly reducing replacement costs and maintenance downtime. The ePTFE laminated media specifically led to a noticeable reduction in pressure drop, contributing to a 7% decrease in energy consumption for the fan motors.

Case Study 2: Pharmaceutical Powder Recovery

Challenge: A pharmaceutical company needed to recover valuable active pharmaceutical ingredients (APIs) from a spray dryer exhaust while ensuring ultra-clean air discharge and preventing cross-contamination. The dust was fine, sticky, and valuable.

Solution: Given the high-value product and stringent cleanroom requirements, a specialized **dust collector filter media** made from FDA-compliant Polyester with a precision-applied ePTFE membrane was chosen. This media offered superior surface filtration, excellent dust cake release, and ensured virtually 100% product recovery and emission control.

Result: The ePTFE membrane media allowed for consistent, high-efficiency capture of the APIs, reducing product loss by 98% compared to previous media. The system's operational pressure drop remained stable, and the cleanability of the filters was exceptional, allowing for longer operational cycles between cleaning and extended media life. This directly impacted profitability through increased product yield and reduced operational costs.

Case Study 3: Woodworking Dust Control & Fire Safety

Challenge: A large furniture manufacturer faced issues with excessive wood dust buildup, leading to equipment wear, poor air quality, and fire hazards. Their existing filters clogged quickly and required constant cleaning, increasing energy consumption.

Solution: The system was retrofitted with anti-static **dust collector filter media** made from Polyester, treated with a durable water and oil repellent finish. The anti-static properties mitigated the risk of static charge buildup (a major fire hazard with wood dust), while the finish improved dust cake release, leading to more effective pulse cleaning.

Result: Air quality within the facility significantly improved, reducing airborne dust levels by over 90%. The enhanced dust release characteristics of the new media led to a 15% reduction in fan energy consumption due to lower average system pressure drop. Filter lifespan increased by 30%, and most importantly, the fire risk associated with static discharge was substantially reduced, creating a safer working environment. "Our previous filters were a constant headache," a plant manager stated, "but the new anti-static **dust filter media** has made a remarkable difference in both efficiency and safety."

Frequently Asked Questions (FAQ) about **Dust Collector Filter Media**

Q1: What is the primary difference between depth filtration and surface filtration in **dust collector filter media**?

A1: Depth filtration (e.g., standard needle felt) captures dust particles within the matrix of the filter media. This allows for high dust holding capacity but can lead to increased pressure drop as particles embed. Surface filtration (e.g., media with an ePTFE membrane laminate) captures nearly all dust particles on the exterior surface of the filter. This results in extremely high filtration efficiency, easy dust cake release during pulse cleaning, lower and more stable pressure drop, and longer filter life. It's ideal for very fine, sticky, or valuable dusts.

Q2: How does temperature affect the choice of **dust filter media**?

A2: Temperature is a critical factor. Different fiber types have specific maximum continuous operating temperatures. Polyester (PET) is suitable up to ~135°C. For higher temperatures (150-200°C), Aramid (Nomex) or PPS (Ryton) are used. For extreme temperatures (up to 260-280°C) or highly corrosive environments, Fiberglass or PTFE **dust collector filter media** are necessary. Operating media above its rated temperature can lead to rapid degradation, loss of strength, and filter failure.

Q3: What does "pressure drop" mean, and why is it important for **dust collector filter media**?

A3: Pressure drop (or differential pressure) is the resistance to airflow as air passes through the filter media. It's measured as the pressure difference across the clean and dirty sides of the filter. A higher pressure drop means the fan has to work harder, consuming more energy. Maintaining an optimal and stable pressure drop is crucial for energy efficiency and effective dust collection. Quality **dust collector filter media** with good dust cake release properties helps maintain low pressure drop.

Q4: How do I determine the correct filter media for my specific dust collection application?

A4: Proper selection involves analyzing several factors: the physical and chemical properties of the dust (particle size, abrasiveness, stickiness, explosiveness), gas stream characteristics (temperature, moisture, chemical composition), and required filtration efficiency. Consulting with a knowledgeable filter media supplier, like Anyafiltermedia.com, is highly recommended. They can perform lab tests on dust samples and recommend the optimal **dust filter material roll** or finished product.

Q5: What are anti-static **dust collector filter media** used for?

A5: Anti-static **dust collector filter media** are designed to dissipate static electricity generated by the friction of dust particles passing through the filter. This is crucial when handling combustible dusts (e.g., wood dust, coal dust, flour, certain chemical powders) to prevent sparks that could ignite an explosion. These media typically incorporate conductive fibers or surface treatments to safely ground static charges, ensuring compliance with ATEX or NFPA regulations.

Q6: What is the typical delivery cycle for custom **dust collector filter media** orders, and what about warranty?

A6: The delivery cycle for custom **dust collector filter media** can vary based on the complexity of the order, material availability, and production schedule. Generally, it ranges from 2-4 weeks after order confirmation for specialized roll goods. For standard items, it can be quicker. We provide a detailed lead time upon quotation. Regarding warranty, our **dust filter media** products typically come with a warranty against manufacturing defects. Specific warranty terms depend on the product type and application, usually outlined in our sales agreements, ensuring client confidence and trust.

Q7: Can **dust collector filter media** be cleaned and reused, and what is the typical lifespan?

A7: Most industrial **dust collector filter media** (especially bag filters) are designed for in-situ cleaning, primarily via pulse-jet systems, allowing for reuse over an extended period. The effectiveness of cleaning depends on the media type, dust characteristics, and cleaning system parameters. The typical lifespan varies greatly: 1-2 years for some standard polyester media in general applications, up to 3-5+ years for high-performance materials like Aramid, PTFE, or P84 in demanding environments, assuming proper system operation and maintenance. Factors like excessive abrasion, chemical attack, or consistent over-temperature can significantly shorten life.

Commitment to Trustworthiness and Customer Support

At Anyafiltermedia.com, our commitment extends beyond delivering superior **dust collector filter media**; it encompasses providing an end-to-end service experience built on trust, transparency, and unwavering support. We understand that filter media is a critical component of your operations, and its reliable performance is paramount.

- Transparent Delivery & Logistics: We provide clear and accurate delivery schedules from the outset, keeping you informed at every stage from order placement to dispatch. Our robust logistics network ensures timely and secure delivery of your **dust filter material roll** or finished products, minimizing disruptions to your operations.

- Comprehensive Quality Assurance: Every batch of **dust collector filter media** undergoes rigorous quality control tests. We adhere to international testing standards and provide relevant certification and test reports upon request, assuring you of the product's performance and compliance.

- Dedicated Customer Support: Our team of filtration experts is available to provide technical assistance, answer your queries, and offer solutions from initial consultation through to post-installation support. We pride ourselves on responsive communication and proactive problem-solving.

- Guaranteed Product Performance: We stand by the quality of our **dust collector filter media** with a clear warranty policy, protecting your investment against manufacturing defects and ensuring the media meets its stated performance specifications under normal operating conditions. Our goal is your complete satisfaction and the long-term success of your dust collection system.

For inquiries regarding specific product specifications, custom solutions, or to discuss your unique filtration challenges, please do not hesitate to reach out. Our experts are ready to provide a tailored consultation and quotation.

Explore Our Dust Collector Filter Media SolutionsConclusion and Industry Outlook

The selection and application of high-quality **dust collector filter media** are pivotal for industrial sustainability, regulatory compliance, and operational efficiency. As industries face increasing pressure to minimize environmental impact and optimize resource utilization, the demand for advanced, energy-efficient, and durable filtration solutions will only intensify. The shift towards specialized materials, intelligent surface treatments like ePTFE membranes, and comprehensive customization capabilities underscores the critical role that expert manufacturers play in this evolving landscape.

By investing in superior **dust filter media** that is precisely engineered for specific applications, companies can achieve significant improvements in air quality, extend equipment lifespan, reduce energy consumption, and minimize maintenance costs. This strategic investment not only safeguards the environment and human health but also drives substantial economic benefits.

"The filtration industry is witnessing a paradigm shift, moving beyond mere particle capture to holistic air quality management solutions. Advanced filter media, particularly those employing surface filtration technologies, are at the forefront of this transformation, enabling industries to achieve near-zero emissions and substantial operational savings. The future of industrial air quality hinges on material innovation and intelligent system integration."

— Environmental Filtration Technologies Forum, 2023. Source: EHSToday - The Future of Industrial Air Filtration"Research in non-woven filter media continues to push boundaries in efficiency and longevity. Novel fiber chemistries, nano-coatings, and optimized web structures are enhancing dust holding capacity while simultaneously reducing pressure drop, presenting significant opportunities for energy conservation in industrial baghouses."

— Journal of Industrial Textiles, Vol. 52, Issue 3, pp. 315-332. Source: Sage Journals - Advances in Filter Media (Example Link)Post time: Aug-07-2025