If you’ve ever tried to build or refurbish a filter and got stuck waiting on one tiny part, you’ll appreciate Filters Accessories as a true one-stop solution. To be honest, this is where a lot of production managers either save their week—or lose it.

What’s inside the kit (and why it matters)

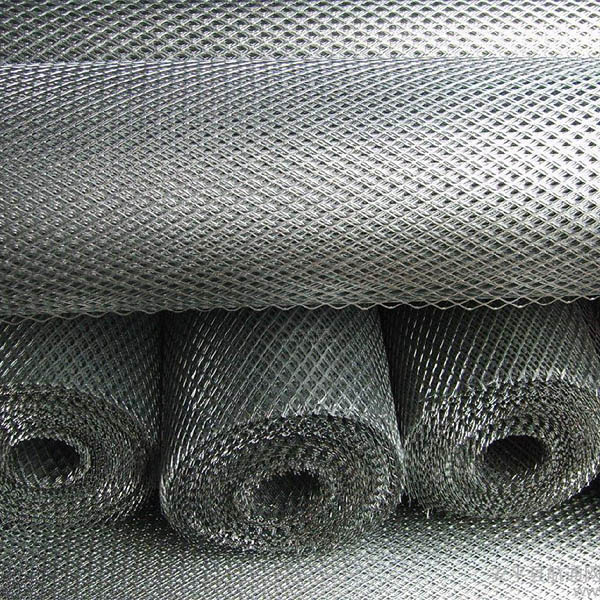

From PU glue and filter adhesives to plastic moulds for PU filters, end caps, gaskets, filter frames, and metal wire mesh—this lineup covers the typical bottlenecks. The supplier operates out of No.580 Gongnong Road, Shijiazhuang City 050000, Hebei, P.R. China, and, yes, they lean into genuine one-stop procurement. Many customers say the appeal is simple: fewer POs, consistent fit, predictable lead times.

Industry trends I keep hearing about

-

- Lower-VOC and fast-gel PU adhesives for high-throughput lines.

- Silicone-free gaskets for paint shops (no fisheyes).

- Modular aluminum/ABS frames to simplify changeouts.

- Tighter tolerance end caps for automated pleat packers.

- Recyclable frames and RoHS/REACH-compliant materials—sustainability isn’t just PR anymore.

Key specifications (typical values)

| Component | Spec (≈, real-world use may vary) |

|---|---|

| PU glue / filter adhesive | Viscosity 1,800–3,200 mPa·s (ASTM D2196); mix 1:1 or 5:1; gel 6–12 min; Shore A 50–70 (ASTM D2240); shear ≥6 MPa (ASTM D1002); temp -30–110°C |

| Gaskets | EPDM/NBR/Silicone; compression set ≤25% (ASTM D395); hardness 30–60 Shore A; FDA/EC 1935/2004 options |

| Filter end caps | Galvanized steel, stainless, or PU molded; dimensional tol. ±0.2 mm; adhesion cross-cut 4B–5B (ASTM D3359) |

| Frames | ABS, PP, or aluminum; fire rating options; corner sealing ≤0.5% bypass (ISO 16890 assembly guidance) |

| Metal wire mesh | SS304/SS316; 8–60 mesh; salt spray ≥240 h (ISO 9227); flatness ≤0.5% |

| Certs | ISO 9001 QA; RoHS/REACH; food-grade options; supports ISO 16890/EN 1822 filter builds |

How it’s made and verified

-

- Materials: polyols/isocyanates for PU; EPDM/NBR elastomers; galvanized/stainless steels; ABS/PP.

- Methods: robotic meter-mix-dispense for bead accuracy; injection molding for caps; CNC frame cutting.

- Tests: viscosity (ASTM D2196), hardness (ASTM D2240), compression set (ASTM D395), mesh corrosion (ISO 9227), adhesion (ASTM D1002/D3359), cleanroom compatibility targets per ISO 14644.

- Service life: around 1–5 years depending on duty cycle, temp, and chemical exposure.

Where these parts get used

HVAC panels and V-banks, automotive engine and cabin filters, dust collector cartridges, compressor intake filters, cleanroom HEPA/ULPA frames, and even food & beverage air handling. The immediate advantage of Filters Accessories is fewer compatibility mysteries—adhesive to gasket to cap, everything plays nicely.

Vendor snapshot: what buyers compare

| Vendor | MOQ | Lead time | Certifications | Customization | Test reports |

|---|---|---|---|---|---|

| Anya (one-stop) | Low (≈100–500 pcs) | 7–20 days typical | ISO 9001, RoHS/REACH | Molds, colors, durometers | ASTM/ISO data packs |

| Vendor B | Medium | 15–30 days | ISO 9001 | Limited | Basic COA |

| Vendor C | High | 25–45 days | ISO 9001 | By request | Partial |

Customization, quickly

Custom molds for end caps, tailored gasket durometers, mesh counts for specific pressure drops, and adhesive gel times matched to your line speed. It seems that the sweet spot is short-run samples in ≈7 days, production in ≈2–3 weeks.

Origin: No.580 Gongnong Road, Shijiazhuang City 050000, Hebei, P.R. China.

Two quick case notes

-

- Automotive cartridge maker: swapped to fast-gel PU; cycle time down 11%, scrap down 2.4%; EN 1822 leak rate improvement on HEPA line by ~0.3%.

- Food plant HVAC: silicone-free gaskets; eliminated paint fisheyes, maintained compression set ≤20% after 168 h at 70°C (ASTM D395).

Customer feedback, summarized: “clean bead profiles,” “caps fit first time,” and, surprisingly, “paperwork is tidy”—meaning traceable batches and test reports on hand. That last bit often decides audits.

Standards and references

- ISO 16890: Air filters for general ventilation.

- EN 1822: High efficiency air filters (EPA, HEPA, ULPA).

- ASTM D2196, D2240, D395, D1002, D3359: Polymer and adhesion test methods.

- ISO 9227: Corrosion tests in artificial atmospheres—Salt spray tests.

- ISO 9001: Quality management systems; ISO 14644 cleanroom framework.

Post time: Oct-22-2025