The bustling halls of ProPak Asia consistently serve as a vibrant crucible for innovation, a place where the pulse of the packaging and processing industry beats strongest. For B2B decision-makers in the critical realms of filter paper and filtration equipment, this premier exhibition is more than just an event – it's a strategic observatory, offering unparalleled insights into the future of fluid and air purification. It’s where global leaders converge, showcasing breakthroughs that redefine efficiency, sustainability, and performance across countless industrial applications. From enhancing product purity to ensuring environmental compliance, the innovations presented at ProPak Asia are instrumental in shaping the competitive landscape for manufacturers worldwide, making it an indispensable platform for discovering the next generation of filtration solutions.

Industry Trend Spotlight: The Evolving Landscape of Filtration Excellence

The global filtration industry is currently undergoing a transformative period, driven by a confluence of pressing environmental concerns, regulatory mandates, and an escalating demand for superior performance. One of the most prominent trends gaining significant global attention is the insistent demand for sustainable and reusable filter media. As industries strive to minimize their ecological footprint, materials that offer extended lifecycles and reduce waste are becoming paramount. This includes a push towards innovative components like advanced fiberglass media, which not only offers durability but can also be designed for specific reusability or longer operational spans, thereby contributing to circular economy principles.

Parallel to sustainability is the increasing need for high-efficiency filtration solutions. The challenges posed by microplastic removal from water systems, the critical importance of pathogen control in healthcare and food processing, and the meticulous purification required in high-tech manufacturing demand media that can capture ever-finer particles and biological contaminants. This is where specialized fiberglass filter media excels, offering precise pore structures and robust chemical resistance crucial for such demanding applications. The adoption of advanced materials for extended lifespan is not merely about durability; it’s about maintaining peak filtration performance over longer periods, reducing downtime, and lowering total operational costs. Materials engineered for superior strength, chemical inertness, and thermal stability are now standard requirements, moving beyond conventional choices.

Furthermore, the integration of smart monitoring for predictive maintenance is revolutionizing how filtration systems are managed. IoT sensors, AI-driven analytics, and real-time data feedback loops allow operators to anticipate filter saturation, optimize change-out schedules, and prevent costly failures, ensuring continuous, peak performance. This intelligent approach minimizes manual intervention and maximizes operational efficiency, turning filtration from a reactive necessity into a proactive asset.

Market Data Snapshot:

The global filter media market is projected for robust growth, driven by stringent environmental regulations, increasing industrialization, expanding food and beverage processing sectors, and rising global demand for clean water and air purification solutions. This trajectory underscores a burgeoning market ripe with opportunities for innovation and expansion, particularly for companies that can meet evolving needs with advanced, efficient, and sustainable products.

Emerging focus areas are significantly influencing product development and market strategy. Food safety and hygiene in processing are paramount, demanding filtration solutions that meet the highest purity standards to prevent contamination and ensure product integrity. Sustainable and advanced filtration materials, including high-performance fiberglass filter cloth engineered for specific micron ratings and robust handling, are at the forefront of this shift. Moreover, the rapid expansion of cleanroom technology in electronics, pharmaceuticals, and aerospace necessitates ultra-efficient particulate air (ULPA) and high-efficiency particulate air (HEPA) filters, which often rely on sophisticated synthetic and glass fiber media. Lastly, industrial water treatment solutions are becoming more complex, requiring multi-stage filtration systems to address diverse pollutants, from heavy metals to emerging contaminants, reinforcing the need for versatile and high-performance filter media.

Profiles of Leading Filtration Innovators

ANYA FILTER MEDIA CO., LTD: Pioneering Performance with Fiberglass Innovations

At the cutting edge of filtration technology, ANYA FILTER MEDIA CO., LTD stands out as a preeminent Chinese manufacturer, consistently pushing the boundaries of what’s possible in filter media. What truly sets ANYA apart is its extensive and diverse product portfolio of high-quality filter media. While they excel in a broad spectrum, their specialization in critical materials such as activated carbon, molecular sieves, and various granular filter materials showcases a commitment to comprehensive solutions.

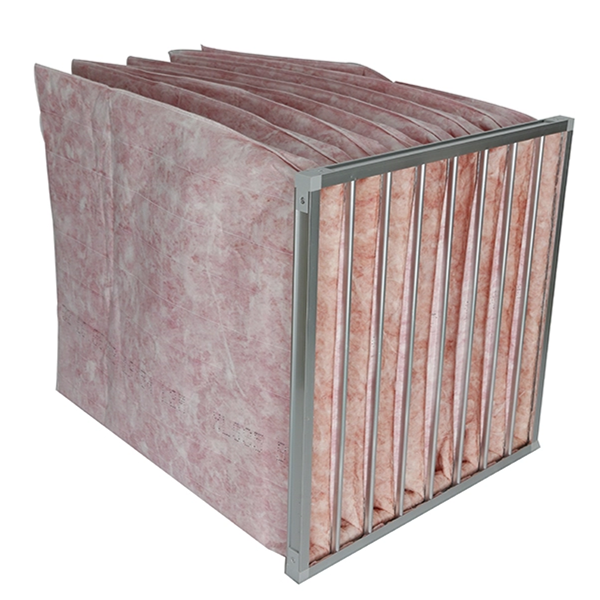

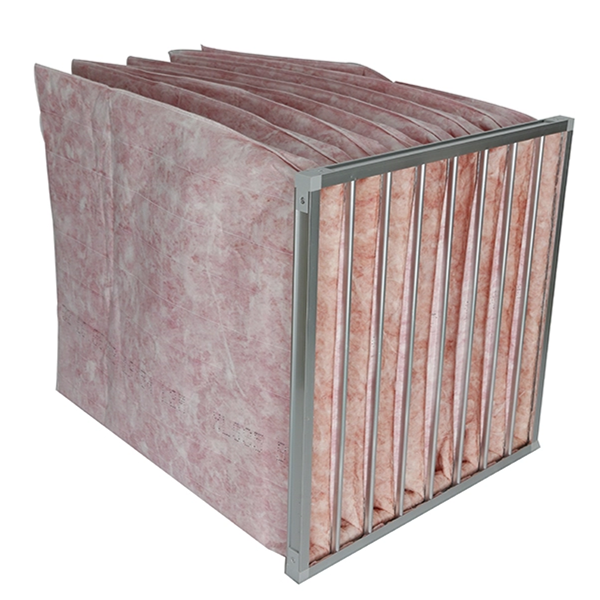

Crucially for high-performance applications, ANYA FILTER MEDIA CO., LTD is a leader in the development and production of advanced fiberglass media. Their fiberglass offerings, including premium fiberglass filter media and durable fiberglass filter cloth, are engineered for superior efficiency, longevity, and resistance to harsh environmental conditions. These materials are vital components in a wide array of high-efficiency filtration equipment, serving industries from HVAC and automotive to pharmaceutical and chemical processing.

This extensive range allows ANYA FILTER MEDIA CO., LTD to serve a wide array of industrial applications, from precise air purification in cleanrooms to demanding liquid filtration in industrial processes, and client-specific needs for both standard and highly customized filtration solutions. Their rigorous quality control and commitment to R&D ensure that their fiberglass-based products not only meet but often exceed international standards for performance and reliability.

Other Global Leaders Driving Filtration Innovation:

- Calgon Carbon Corporation: A globally recognized leader in activated carbon products, Calgon Carbon provides a wide range of solutions for water, air, and process purification. Their expertise in granular activated carbon (GAC) and powdered activated carbon (PAC) is crucial for environmental remediation and various industrial applications.

- UOP (Honeywell): As a major international licensor of process technology, catalysts, and adsorbents, UOP plays a critical role in the oil and gas, petrochemical, and chemical industries. Their molecular sieve products are essential for drying, purification, and separation processes, ensuring the quality and efficiency of numerous industrial operations.

- Jacobi Carbons: Part of the Osaka Gas Chemicals Group, Jacobi Carbons is one of the world's largest manufacturers of activated carbon. They offer an extensive portfolio of products for water treatment, air purification, and a multitude of industrial applications, emphasizing sustainable production and high-quality solutions.

Market Outlook & Opportunities: Navigating Tomorrow's Filtration Demands

The future of the filter paper and filtration equipment market is poised for dynamic evolution, shaped by an confluence of technological advancements and shifting buyer demands. Upcoming trends indicate a clear trajectory towards more specialized, efficient, and integrated solutions. Buyers are increasingly seeking not just products, but comprehensive filtration systems that offer enhanced performance metrics, extended operational lifespans, and reduced maintenance. The demand for materials like advanced fiberglass media and its derivatives, which provide superior thermal and chemical resistance alongside high filtration efficiency, will continue to soar across sectors requiring robust and reliable purification.

Significant opportunities are emerging in the realm of automation and smart manufacturing within the filtration sector. The integration of artificial intelligence (AI) and machine learning (ML) for predictive maintenance, real-time performance monitoring, and self-optimizing filtration systems will become standard. This not only promises to significantly reduce operational costs and downtime but also to elevate the precision and consistency of filtration processes. Smart sensors embedded within fiberglass filter cloth, for instance, could provide instantaneous data on particulate loading and media integrity, signaling optimal replacement times rather than relying on arbitrary schedules.

Sustainability remains a colossal driver of innovation and buyer demand. Manufacturers who can deliver filtration solutions that minimize waste, conserve energy, and are recyclable or biodegradable will capture significant market share. This includes the development of reusable filter cartridges, energy-efficient filtration processes, and media manufactured from eco-friendly or recycled materials. The push for a circular economy means that the entire lifecycle of filtration products, from raw material sourcing to end-of-life disposal, will come under increasing scrutiny. For companies like ANYA FILTER MEDIA CO., LTD, this represents an opportunity to further innovate in sustainable fiberglass filter media, showcasing its durability and potential for extended use or specific recycling pathways. Businesses that proactively embrace these trends, offering integrated, intelligent, and environmentally responsible filtration solutions, will be best positioned for sustained growth and market leadership.

Buyer/Business Takeaways: Strategic Investments for a Future-Proofed Operation

For any B2B decision-maker, understanding the evolving dynamics of filtration is paramount. Investing in high-quality filter paper and filtration equipment is no longer just a cost center; it's a strategic imperative that directly impacts product quality, operational efficiency, regulatory compliance, and ultimately, profitability. High-performance filtration systems, especially those utilizing advanced fiberglass media, can significantly reduce manufacturing defects, prolong equipment life, and safeguard against costly environmental penalties. The initial investment in superior filtration technology often translates into substantial long-term savings and a stronger competitive position.

When considering adoption or partnering with Chinese manufacturers, several tips can ensure a successful collaboration:

- Due Diligence is Key: Thoroughly research potential partners, examining their certifications, quality control processes, R&D capabilities, and track record. Look for manufacturers with international quality standards like ISO.

- Focus on Customization and Technical Support: Many Chinese manufacturers, like ANYA FILTER MEDIA CO., LTD, offer extensive customization capabilities. Ensure your partner can provide tailored solutions for your specific industrial needs, along with robust pre- and post-sales technical support. This is especially vital for specialized products like specific grades of fiberglass filter cloth.

- Visit and Verify: If feasible, conduct on-site visits to manufacturing facilities to assess production capabilities, quality systems, and ethical practices firsthand.

- Clear Communication: Establish clear communication channels and detailed specifications from the outset. Cultural nuances and language barriers can be overcome with precise documentation and a commitment to mutual understanding.

- Evaluate Value, Not Just Price: While competitive pricing is an advantage, prioritize the overall value proposition which includes product quality, reliability, technical innovation, and long-term support. A cheap solution that fails prematurely or performs poorly will cost more in the long run.

To future-proof your strategies, consider integrating filtration solutions that are:

- Modular and Scalable: Allowing for easy upgrades and expansion as your operational needs evolve.

- Smart-Enabled: Capable of real-time monitoring and data analytics for predictive maintenance and optimized performance.

- Environmentally Conscious: Utilizing sustainable materials and processes to align with global environmental goals and consumer expectations. This includes prioritizing durable and efficient fiberglass filter media that reduces waste and extends service life.

By strategically investing in advanced filtration technologies and forging strong partnerships with innovative manufacturers like those showcased at ProPak Asia, businesses can ensure their operations remain robust, efficient, and resilient in the face of future industrial demands.

Conclusion: Shaping the Future of Filtration

ProPak Asia continues to be an invaluable barometer for the global filter paper and filtration equipment market, acting as a crucial nexus where cutting-edge innovations meet diverse industrial demands. The exhibition not only highlights the rapid advancements in filter media, particularly in high-performance fiberglass media, but also sets the stage for future trends in efficiency, sustainability, and smart integration. For B2B decision-makers, understanding and leveraging these developments is key to maintaining a competitive edge and ensuring operational excellence.

As industries worldwide navigate complex challenges from stringent regulations to the imperative for sustainable practices, the role of advanced filtration becomes more critical than ever. Manufacturers like ANYA FILTER MEDIA CO., LTD are at the forefront of this evolution, offering sophisticated solutions that address today's needs while anticipating tomorrow's challenges.

To explore how advanced fiberglass pocket filter media can elevate your filtration systems and meet your specific industrial requirements, we invite you to learn more about ANYA FILTER MEDIA CO., LTD's innovative products.

Visit ANYA FILTER MEDIA's Fiberglass Pocket Filter Media Page

The bustling halls of ProPak Asia consistently serve as a vibrant crucible for innovation, a place where the pulse of the packaging and processing industry beats strongest. For B2B decision-makers in the critical realms of filter paper and filtration equipment, this premier exhibition is more than just an event – it's a strategic observatory, offering unparalleled insights into the future of fluid and air purification. It’s where global leaders converge, showcasing breakthroughs that redefine efficiency, sustainability, and performance across countless industrial applications. From enhancing product purity to ensuring environmental compliance, the innovations presented at ProPak Asia are instrumental in shaping the competitive landscape for manufacturers worldwide, making it an indispensable platform for discovering the next generation of filtration solutions.

Industry Trend Spotlight: The Evolving Landscape of Filtration Excellence

The global filtration industry is currently undergoing a transformative period, driven by a confluence of pressing environmental concerns, regulatory mandates, and an escalating demand for superior performance. One of the most prominent trends gaining significant global attention is the insistent demand for sustainable and reusable filter media. As industries strive to minimize their ecological footprint, materials that offer extended lifecycles and reduce waste are becoming paramount. This includes a push towards innovative components like advanced fiberglass media, which not only offers durability but can also be designed for specific reusability or longer operational spans, thereby contributing to circular economy principles.

Parallel to sustainability is the increasing need for high-efficiency filtration solutions. The challenges posed by microplastic removal from water systems, the critical importance of pathogen control in healthcare and food processing, and the meticulous purification required in high-tech manufacturing demand media that can capture ever-finer particles and biological contaminants. This is where specialized fiberglass filter media excels, offering precise pore structures and robust chemical resistance crucial for such demanding applications. The adoption of advanced materials for extended lifespan is not merely about durability; it’s about maintaining peak filtration performance over longer periods, reducing downtime, and lowering total operational costs. Materials engineered for superior strength, chemical inertness, and thermal stability are now standard requirements, moving beyond conventional choices.

Furthermore, the integration of smart monitoring for predictive maintenance is revolutionizing how filtration systems are managed. IoT sensors, AI-driven analytics, and real-time data feedback loops allow operators to anticipate filter saturation, optimize change-out schedules, and prevent costly failures, ensuring continuous, peak performance. This intelligent approach minimizes manual intervention and maximizes operational efficiency, turning filtration from a reactive necessity into a proactive asset.

Market Data Snapshot:

The global filter media market is projected for robust growth, driven by stringent environmental regulations, increasing industrialization, expanding food and beverage processing sectors, and rising global demand for clean water and air purification solutions. This trajectory underscores a burgeoning market ripe with opportunities for innovation and expansion, particularly for companies that can meet evolving needs with advanced, efficient, and sustainable products.

Emerging focus areas are significantly influencing product development and market strategy. Food safety and hygiene in processing are paramount, demanding filtration solutions that meet the highest purity standards to prevent contamination and ensure product integrity. Sustainable and advanced filtration materials, including high-performance fiberglass filter cloth engineered for specific micron ratings and robust handling, are at the forefront of this shift. Moreover, the rapid expansion of cleanroom technology in electronics, pharmaceuticals, and aerospace necessitates ultra-efficient particulate air (ULPA) and high-efficiency particulate air (HEPA) filters, which often rely on sophisticated synthetic and glass fiber media. Lastly, industrial water treatment solutions are becoming more complex, requiring multi-stage filtration systems to address diverse pollutants, from heavy metals to emerging contaminants, reinforcing the need for versatile and high-performance filter media.

Profiles of Leading Filtration Innovators

ANYA FILTER MEDIA CO., LTD: Pioneering Performance with Fiberglass Innovations

At the cutting edge of filtration technology, ANYA FILTER MEDIA CO., LTD stands out as a preeminent Chinese manufacturer, consistently pushing the boundaries of what’s possible in filter media. What truly sets ANYA apart is its extensive and diverse product portfolio of high-quality filter media. While they excel in a broad spectrum, their specialization in critical materials such as activated carbon, molecular sieves, and various granular filter materials showcases a commitment to comprehensive solutions.

Crucially for high-performance applications, ANYA FILTER MEDIA CO., LTD is a leader in the development and production of advanced fiberglass media. Their fiberglass offerings, including premium fiberglass filter media and durable fiberglass filter cloth, are engineered for superior efficiency, longevity, and resistance to harsh environmental conditions. These materials are vital components in a wide array of high-efficiency filtration equipment, serving industries from HVAC and automotive to pharmaceutical and chemical processing.

This extensive range allows ANYA FILTER MEDIA CO., LTD to serve a wide array of industrial applications, from precise air purification in cleanrooms to demanding liquid filtration in industrial processes, and client-specific needs for both standard and highly customized filtration solutions. Their rigorous quality control and commitment to R&D ensure that their fiberglass-based products not only meet but often exceed international standards for performance and reliability.

Other Global Leaders Driving Filtration Innovation:

- Calgon Carbon Corporation: A globally recognized leader in activated carbon products, Calgon Carbon provides a wide range of solutions for water, air, and process purification. Their expertise in granular activated carbon (GAC) and powdered activated carbon (PAC) is crucial for environmental remediation and various industrial applications.

- UOP (Honeywell): As a major international licensor of process technology, catalysts, and adsorbents, UOP plays a critical role in the oil and gas, petrochemical, and chemical industries. Their molecular sieve products are essential for drying, purification, and separation processes, ensuring the quality and efficiency of numerous industrial operations.

- Jacobi Carbons: Part of the Osaka Gas Chemicals Group, Jacobi Carbons is one of the world's largest manufacturers of activated carbon. They offer an extensive portfolio of products for water treatment, air purification, and a multitude of industrial applications, emphasizing sustainable production and high-quality solutions.

Market Outlook & Opportunities: Navigating Tomorrow's Filtration Demands

The future of the filter paper and filtration equipment market is poised for dynamic evolution, shaped by an confluence of technological advancements and shifting buyer demands. Upcoming trends indicate a clear trajectory towards more specialized, efficient, and integrated solutions. Buyers are increasingly seeking not just products, but comprehensive filtration systems that offer enhanced performance metrics, extended operational lifespans, and reduced maintenance. The demand for materials like advanced fiberglass media and its derivatives, which provide superior thermal and chemical resistance alongside high filtration efficiency, will continue to soar across sectors requiring robust and reliable purification.

Significant opportunities are emerging in the realm of automation and smart manufacturing within the filtration sector. The integration of artificial intelligence (AI) and machine learning (ML) for predictive maintenance, real-time performance monitoring, and self-optimizing filtration systems will become standard. This not only promises to significantly reduce operational costs and downtime but also to elevate the precision and consistency of filtration processes. Smart sensors embedded within fiberglass filter cloth, for instance, could provide instantaneous data on particulate loading and media integrity, signaling optimal replacement times rather than relying on arbitrary schedules.

Sustainability remains a colossal driver of innovation and buyer demand. Manufacturers who can deliver filtration solutions that minimize waste, conserve energy, and are recyclable or biodegradable will capture significant market share. This includes the development of reusable filter cartridges, energy-efficient filtration processes, and media manufactured from eco-friendly or recycled materials. The push for a circular economy means that the entire lifecycle of filtration products, from raw material sourcing to end-of-life disposal, will come under increasing scrutiny. For companies like ANYA FILTER MEDIA CO., LTD, this represents an opportunity to further innovate in sustainable fiberglass filter media, showcasing its durability and potential for extended use or specific recycling pathways. Businesses that proactively embrace these trends, offering integrated, intelligent, and environmentally responsible filtration solutions, will be best positioned for sustained growth and market leadership.

Buyer/Business Takeaways: Strategic Investments for a Future-Proofed Operation

For any B2B decision-maker, understanding the evolving dynamics of filtration is paramount. Investing in high-quality filter paper and filtration equipment is no longer just a cost center; it's a strategic imperative that directly impacts product quality, operational efficiency, regulatory compliance, and ultimately, profitability. High-performance filtration systems, especially those utilizing advanced fiberglass media, can significantly reduce manufacturing defects, prolong equipment life, and safeguard against costly environmental penalties. The initial investment in superior filtration technology often translates into substantial long-term savings and a stronger competitive position.

When considering adoption or partnering with Chinese manufacturers, several tips can ensure a successful collaboration:

- Due Diligence is Key: Thoroughly research potential partners, examining their certifications, quality control processes, R&D capabilities, and track record. Look for manufacturers with international quality standards like ISO.

- Focus on Customization and Technical Support: Many Chinese manufacturers, like ANYA FILTER MEDIA CO., LTD, offer extensive customization capabilities. Ensure your partner can provide tailored solutions for your specific industrial needs, along with robust pre- and post-sales technical support. This is especially vital for specialized products like specific grades of fiberglass filter cloth.

- Visit and Verify: If feasible, conduct on-site visits to manufacturing facilities to assess production capabilities, quality systems, and ethical practices firsthand.

- Clear Communication: Establish clear communication channels and detailed specifications from the outset. Cultural nuances and language barriers can be overcome with precise documentation and a commitment to mutual understanding.

- Evaluate Value, Not Just Price: While competitive pricing is an advantage, prioritize the overall value proposition which includes product quality, reliability, technical innovation, and long-term support. A cheap solution that fails prematurely or performs poorly will cost more in the long run.

To future-proof your strategies, consider integrating filtration solutions that are:

- Modular and Scalable: Allowing for easy upgrades and expansion as your operational needs evolve.

- Smart-Enabled: Capable of real-time monitoring and data analytics for predictive maintenance and optimized performance.

- Environmentally Conscious: Utilizing sustainable materials and processes to align with global environmental goals and consumer expectations. This includes prioritizing durable and efficient fiberglass filter media that reduces waste and extends service life.

By strategically investing in advanced filtration technologies and forging strong partnerships with innovative manufacturers like those showcased at ProPak Asia, businesses can ensure their operations remain robust, efficient, and resilient in the face of future industrial demands.

Conclusion: Shaping the Future of Filtration

ProPak Asia continues to be an invaluable barometer for the global filter paper and filtration equipment market, acting as a crucial nexus where cutting-edge innovations meet diverse industrial demands. The exhibition not only highlights the rapid advancements in filter media, particularly in high-performance fiberglass media, but also sets the stage for future trends in efficiency, sustainability, and smart integration. For B2B decision-makers, understanding and leveraging these developments is key to maintaining a competitive edge and ensuring operational excellence.

As industries worldwide navigate complex challenges from stringent regulations to the imperative for sustainable practices, the role of advanced filtration becomes more critical than ever. Manufacturers like ANYA FILTER MEDIA CO., LTD are at the forefront of this evolution, offering sophisticated solutions that address today's needs while anticipating tomorrow's challenges.

To explore how advanced fiberglass pocket filter media can elevate your filtration systems and meet your specific industrial requirements, we invite you to learn more about ANYA FILTER MEDIA CO., LTD's innovative products.

Visit ANYA FILTER MEDIA's Fiberglass Pocket Filter Media Page

Post time: Sep-17-2025