What’s Changing in Air Filter Paper — And Why It Matters Now

If you work around industrial dust, engines, or HVAC, you’ve heard the phrase air filter paper material more times than you can count. Lately, the conversation has shifted: tighter efficiency targets, tougher emissions rules, and a lot more interest in stable supply chains. To be honest, the market is leaner and more pragmatic. People want consistent batches, verifiable test data, and flexible converting. That’s the story we’re hearing from buyers and maintenance teams alike.

Core Specs You Should Actually Care About

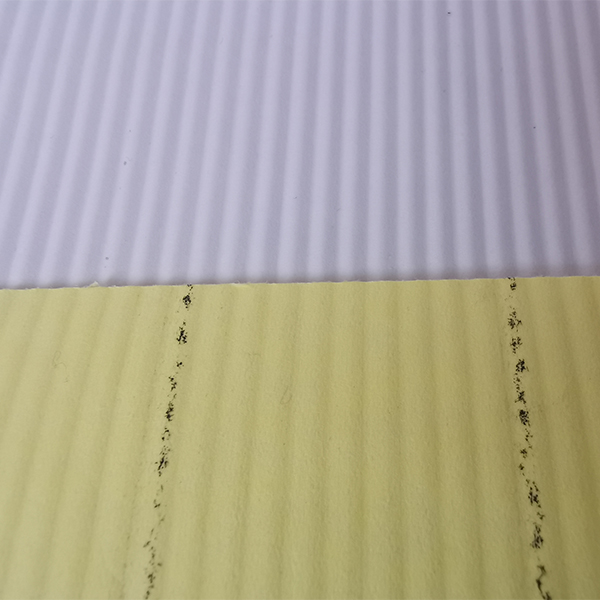

The current generation of air filter paper material is typically cellulose-based or a cellulose/synthetic blend. In our tests and customer trials, blends bring better wet strength and more stable pore structure under pulse and pleat stress. Real-world use may vary (it always does), but the numbers below are a useful starting point.

| Parameter | Typical Value | Notes |

|---|---|---|

| Fiber System | Cellulose or ≈80% cellulose + 20% synthetic | Acrylic resin impregnation |

| Basis Weight | 105–180 g/m² | Per TAPPI/ISO methods |

| Air Permeability | 110–850 L/m²·s | Frazier/Bendtsen equivalents |

| Thickness | ≈0.3–0.7 mm | Calendered grades vary |

| Initial Efficiency | 30–95% @ target particle size | ISO 16890 / ISO 5011 contexts |

How It’s Made (Short Version)

Process flow for air filter paper material: pulp selection → wet forming → resin impregnation (acrylic) → drying/curing → calendering → slitting/rewind → QA. Tests typically include basis weight (TAPPI T410), thickness (T411), air permeability (ISO 5636-5/Bendtsen equivalent), burst, stiffness, pore size, and dust loading per ISO 5011 or analogous methods. Service life ranges from a few months in dusty quarries to 12–24 months in clean HVAC with proper prefiltration.

Where It Works Best

- Automotive and off-road engine intake filters (ISO 5011 test regimes)

- Air compressors and gas turbines (pre-filter stages)

- HVAC pre/medium filters under ISO 16890 classification

- Agricultural and construction machinery; small engines; generators

Many customers say the blended grades hold pleat geometry better in humid seasons—surprisingly noticeable in coastal facilities.

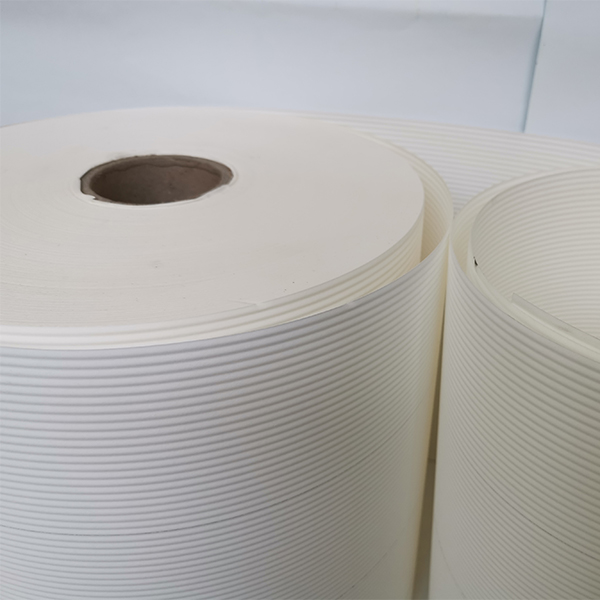

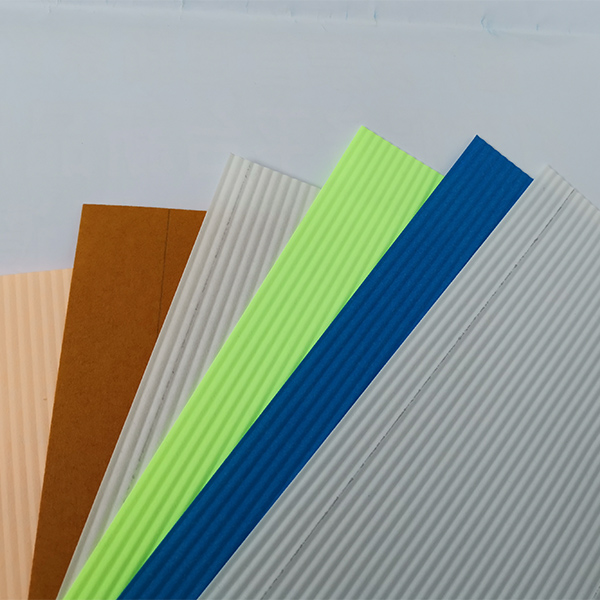

Customization Options

Tuning air filter paper material is straightforward: adjust resin pick-up for wet strength, tweak fiber blend for pore size distribution, add hydrophobic sizing, and specify caliper and stiffness for pleating. Converters often request roll widths from 20–1270 mm, core IDs 3–6 inches, and tight moisture control for stable forming. Origin for this product line: No.580 Gongnong Road, Shijiazhuang City 050000, Hebei, P.R. China.

Quick Case Notes

A quarry fleet switched to a 80/20 blend, same basis weight, and saw ≈18% longer service intervals on intake filters (dust loading test mirrored ISO 5011). Another HVAC client moved to a medium-weight grade and hit ISO 16890 ePM1 50% after pairing with a robust prefilter—energy drop was modest, according to their BMS logs.

Vendor Landscape (Snapshot)

| Vendor | Blend | Basis Wt. | Certifications | Lead Time | Notes |

|---|---|---|---|---|---|

| Anya Filter Media | Cellulose / 80:20 blend | 105–180 g/m² | ISO 9001, RoHS (on request) | ≈2–4 weeks | Custom widths; stable acrylic resin |

| Ahlstrom | Cellulose/synthetic | Wide range | ISO 9001/14001 | Varies by plant | Global footprint |

| H&V | Advanced nonwovens | Application-specific | ISO 9001 | Project-based | High-performance focus |

Publicly available info; lead times and specs may change.

Standards, Compliance, and What to Ask

- Specify target classification (ISO 16890 for HVAC; ISO 5011 for engine intake)

- Request basis weight and permeability COAs for each lot

- Check resin system and VOCs; ask for RoHS/REACH where applicable

- Verify testing methods (TAPPI T410, ISO 5636-5) to avoid apples-to-oranges comparisons

Citations

- ISO 16890: Air filters for general ventilation.

- ISO 5011: Inlet air cleaning equipment for internal combustion engines.

- TAPPI T410: Grammage of paper and paperboard.

- ISO 5636-5: Determination of air permeance (Bendtsen method).

- GB/T 14295: Air filters for general ventilation (China).

Post time: Oct-06-2025