ມ້ວນສື່ Polypropylene Laminate ສັງເຄາະ

ມ້ວນສື່ polypropylene laminate ສັງເຄາະ

ແອັບພລິເຄຊັນ:

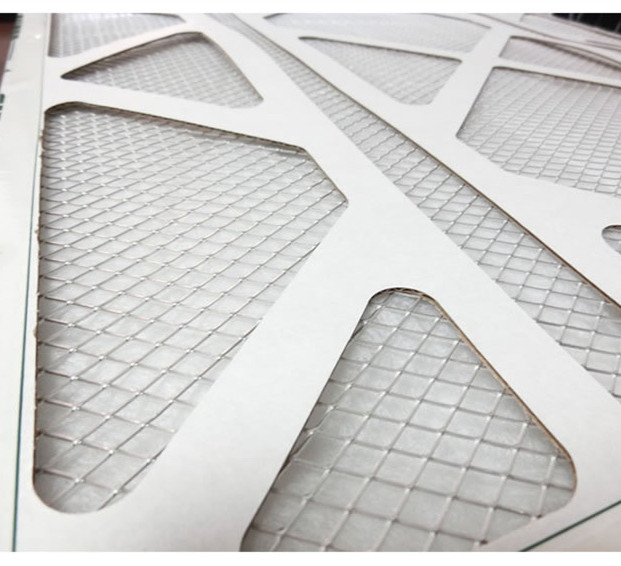

ໃຊ້ສໍາລັບການຜະລິດການກັ່ນຕອງ pleated

Pre-filter ສໍາລັບລະບົບການກັ່ນຕອງອາກາດ

ເຫມາະສໍາລັບການກັ່ນຕອງປະເພດພັບ

ຄຸນນະສົມບັດຜະລິດຕະພັນ:

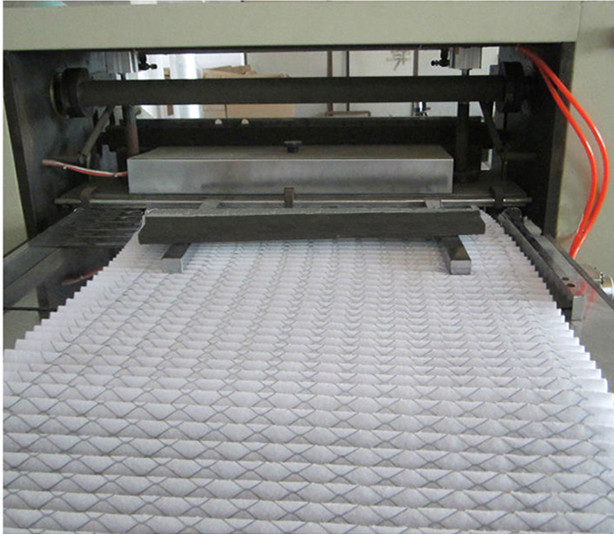

ການນໍາໃຊ້ polypropylene ສັງເຄາະ, ຄ່ອຍໆ encryption ຂະບວນການຜະລິດ;

ການຕໍ່ຕ້ານເບື້ອງຕົ້ນຕ່ໍາ, ຄວາມອາດສາມາດຖືຂີ້ຝຸ່ນສູງ;

ທົນທານຕໍ່ໄຟໄຫມ້ທີ່ດີ, ມາດຕະຖານການຈັດປະເພດໄຟສາມາດຕອບສະຫນອງເອີຣົບ DIN53438-F1;

ຄວາມທົນທານຕໍ່ຄວາມຊຸ່ມຊື່ນສາມາດບັນລຸ 100%;

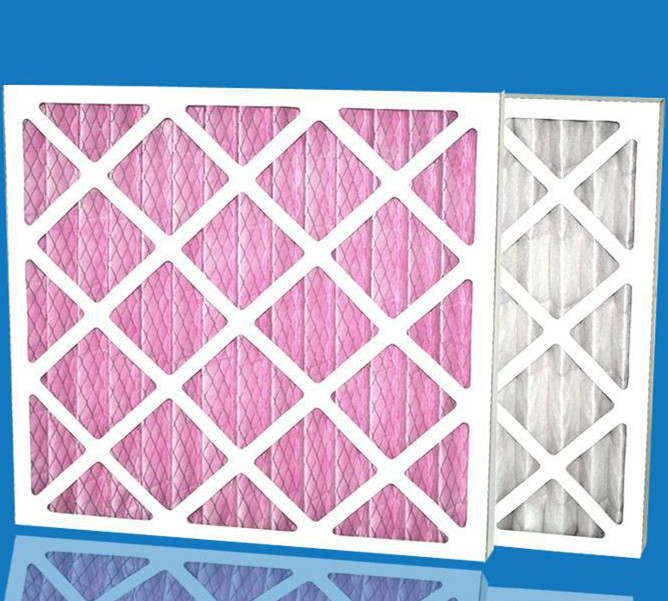

| ບໍ່. | ລາຍການເລກທີ. | ລາຍລະອຽດ | |

| 1 | G4 ຕາຫນ່າງເສັ້ນລວດ laminated media ສີຟ້າ/ສີຂາວ | ກວ້າງ 24" / 610mm * ຍາວ 150m ສື່ສີຂາວ: 610mm width; ຕາຫນ່າງສາຍ: width 580mm |

|

| 2 | 25"/635mm width * ຍາວ 150m ສື່ສີຂາວ: 635mm width; ຕາຫນ່າງສາຍ: width 605mm |

||

| 3 | 20" / 508mm width * ຍາວ 150m ສື່ມວນຊົນສີຂາວ: 508mm width; ຕາຫນ່າງສາຍ: width 478mm |

||

| 4 | 28"/711mm width * ຍາວ 150m ສື່ສີຂາວ: 711mm width; ຕາຫນ່າງສາຍ: width 681mm |

||

| ປະເພດ | ຂະໜາດ | ການຈັບກຸມໂດຍສະເລ່ຍ | ອາກາດ ຄວາມໄວ |

ເບື້ອງຕົ້ນ ຄວາມກົດດັນ |

ອຸນຫະພູມສູງ ℃ | |

| W×L×H | ການກັ່ນຕອງ | % | m/s | ແຕ່ | ||

| ຫ້ອງຮຽນ | ||||||

| AY-G3 | 0.61m*150m | G3 | ≤50 | 2.5 | 60 | 80 |

| IS-G4 | 0.61m*150m | G4 | ≤82 | 2.5 | 75 | 80 |

What is Synthetic Air Filter Media and Why is it Used in Filtration?

Synthetic air filter media is a man-made filtration material composed of engineered polymers such as polyester, polypropylene, or blended fibers. Unlike traditional materials like fiberglass or cellulose, synthetic media offers superior durability, moisture resistance, and customizable filtration efficiency. It is widely used in HVAC systems, automotive filters, and industrial applications because of its ability to capture fine particles while maintaining high airflow rates. The material’s hydrophobic properties prevent mold and bacterial growth, making it ideal for humid environments. Additionally, synthetic media can be electrostatically charged to enhance particle attraction, improving filtration without increasing airflow resistance. Its versatility, longevity, and performance consistency make it a preferred choice for modern filtration needs where reliability and efficiency are critical.

Multi-Layer Synthetic Air Filter Rolls for High Dust Holding Capacity

Multi-layer synthetic air filter rolls are designed to maximize dust-holding capacity while maintaining optimal airflow. These filters use a gradient density structure, with progressively finer layers that capture larger particles first while allowing smaller ones to be trapped deeper within the media. This design prevents premature clogging and extends filter life, reducing maintenance frequency. The synthetic fibers provide high tensile strength, resisting tears and deformation even under heavy particulate loads. Applications include commercial HVAC systems, industrial dust collectors, and automotive air intake filters, where high dust loads are common. The multi-layer approach ensures consistent performance over time, making these rolls cost-effective for high-demand environments that require both efficiency and longevity.

Synthetic vs Fiberglass Air Filter Media

Synthetic air filter media outperforms fiberglass in several key aspects, including durability, moisture resistance, and filtration efficiency. While fiberglass is cost-effective and provides decent filtration, it is fragile and prone to tearing, especially in high-velocity airflow systems. Synthetic media, on the other hand, is more robust, resistant to humidity, and can be engineered for higher dust-holding capacity. Fiberglass filters often require a supportive frame, whereas synthetic media maintains structural integrity independently. Additionally, synthetic filters can incorporate electrostatic enhancement for better particle capture without sacrificing airflow. However, fiberglass remains useful in high-temperature applications where certain synthetic materials may degrade. For most modern HVAC and automotive uses, synthetic media is the superior choice due to its balance of strength, efficiency, and longevity.