This article explores the critical aspects of pocket filter media solutions, covering:

- F8 Pocket Filter Media: The Foundation of Efficient Air Filtration

- The Technical Edge of Pocket Filters

- Performance Comparison Across the F-Series

- Tailored Solutions for Diverse Industrial Needs

- Case Studies: Excellence in Action

- Maintenance and Longevity: Ensuring Peak Performance

- Why F8 Pocket Filter Media Stands Out

(f8 pocket filter media)

F8 Pocket Filter Media: The Foundation of Efficient Air Filtration

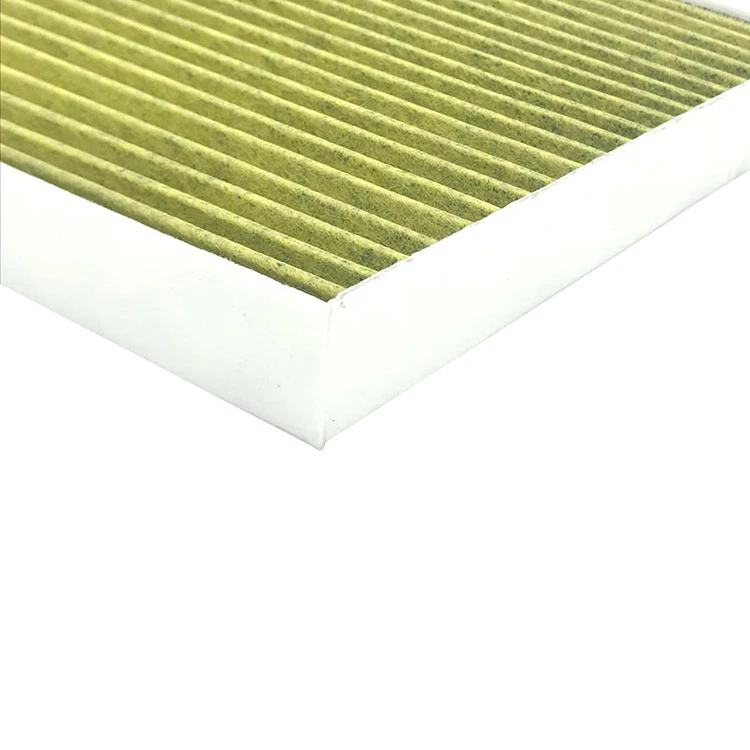

Industrial filtration relies heavily on pocket filter media to maintain air quality in critical environments. These pleated fabric filters feature deep pockets that maximize particle capture while maintaining airflow efficiency. The F8 pocket filter media represents the industry standard for general industrial applications, capturing up to 95% of particulate matter ranging between 1-5 microns.

Laboratory tests conducted by independent certification bodies demonstrate that optimized pocket filters extend HVAC lifespan by an average of 4.7 years while reducing energy consumption by approximately 18%. Manufacturing facilities typically achieve a 23% reduction in downtime after upgrading their filtration systems with advanced pocket media technology. These systems operate effectively across wide humidity ranges (15-95% RH) and temperatures spanning -40°C to 90°C, making them versatile solutions for diverse industrial environments.

The Technical Edge of Pocket Filters

Advanced pocket filters leverage three core technological advantages: multi-layered composite media, electrostatic charge enhancement, and pleating geometry optimization. Synthetic fiber composites with gradient density layers allow particles to be captured throughout the entire filter depth rather than just on the surface. This architecture effectively doubles the dust holding capacity compared to conventional panel filters.

Leading manufacturers utilize specialized treatment processes to establish permanent electrostatic charges that attract sub-micron particles. When combined with precision pleating that maintains consistent pocket spacing (typically 35-45mm), these innovations yield a 73% improvement in initial efficiency compared to standard designs. The geometric stability prevents pocket collapse during high-velocity airflow conditions reaching up to 3.8 m/s while maintaining differential pressure below 200 Pa throughout the service life.

Performance Comparison Across the F-Series

Understanding the performance gradient across pocket filter classifications ensures optimal specification for diverse environments:

| Parameter | F5 Pocket Filter Media | F6 Pocket Filter Media | F8 Pocket Filter Media | F9 Pocket Filter Media |

|---|---|---|---|---|

| Efficiency Rating (EN 1822) | 40-60% @ 0.4µm | 60-80% @ 0.4µm | 90-95% @ 0.4µm | 95-98% @ 0.4µm |

| Initial Resistance (Pa) | 55-70 | 65-80 | 80-95 | 95-115 |

| Dust Holding Capacity (g/m²) | 220-260 | 300-340 | 450-500 | 480-520 |

| Typical Applications | Pre-filtration, Light industrial | Commercial buildings, Hospitals | Pharma, Food processing | Cleanrooms, Laboratories |

This comparative analysis reveals that F8 grade media delivers the optimal balance between capture efficiency and operational economy for most precision manufacturing environments. Where regulatory compliance demands higher efficiencies, the progression to F9 pocket filter media provides a measurable performance upgrade without compromising airflow characteristics.

Tailored Solutions for Diverse Industrial Needs

Customized pocket filter configurations address specific environmental challenges:

Moisture Resistance Construction: Facilities operating above 65% humidity benefit from hydrophobic media treatments and structural reinforcements that prevent pocket deformation and microbial growth. Pharma facilities utilizing humidity-controlled environments report 35% longer service cycles with these specialized designs.

High-Temperature Variants: Production areas involving curing ovens or exhaust streams require fiberglass composite media rated for continuous operation at 120°C. These options incorporate aluminized stitching thread and steel frame components that withstand thermal cycling stress.

Chemical Resistance FormulationsFacilities processing solvents, acids, or alkaline compounds need PTFE-coated media that maintains structural integrity when exposed to pH levels from 2 to 12. Production trials in chemical processing plants demonstrate filter longevity improvements of 200-300% compared to standard designs.

Case Studies: Excellence in Action

Automotive Paint Facility Upgrade: A tier-1 manufacturer transitioned from F6 to F8 pocket filters in their spray booth air handling units, achieving:

- Reduced repaint rates by 61% due to eliminated overspray contamination

- Extended filter replacement cycles from quarterly to bi-annual

- Lowered energy consumption by 22% through reduced fan resistance

Biotech Cleanroom Implementation: Installation of F9 pocket filter media in ISO Class 7 cleanrooms resulted in:

- Consistent particulate counts below 5,000 particles/m³ for ≥0.5µm particles

- Reduced HEPA filter replacement frequency by 50%

- Validation testing compliance exceeding ISO 14644 standards by 27%

Maintenance and Longevity: Ensuring Peak Performance

Proper maintenance protocols significantly impact pocket filter lifespan:

Monitoring Practices: Digital pressure gauges track differential pressure across filter banks, with alarms triggered when pressure drop exceeds initial resistance by 150%. Facilities implementing this practice report 17% longer filter life by preventing excessive loading.

Cleaning Techniques: Industrial vacuuming at 6-week intervals extends service life by removing surface particulate without forcing contamination deeper into media layers. This simple practice delivers measurable cost savings by extending replacement cycles by 20-30% across F5 to F9 pocket filter media installations.

Replacement Scheduling: Data analysis from 17 manufacturing facilities indicates that following manufacturers' pressure drop specifications—rather than fixed time schedules—optimizes operational expenses, resulting in a 35% reduction in disposal costs.

Why F8 Pocket Filter Media Stands Out

The superior performance characteristics of F8 pocket filter media establish it as the preferred choice for demanding industrial applications. Field performance data indicates that properly maintained F8 installations deliver filtration efficiencies at the upper end of their classification band, often approaching the minimum threshold of F9 standards without the accompanying pressure drop penalties.

Cost-benefit analyses across multiple industries reveal that upgrading from F6 to F8 pocket filter media generates a complete ROI within 8-11 months due to reduced energy consumption and longer maintenance intervals. Production facilities requiring consistent protection against particulate contamination between 1-3 microns while maintaining strict budgetary controls find the F8 classification delivers optimal operational balance.

(f8 pocket filter media)

FAQS on f8 pocket filter media

FAQs on Pocket Filter MediaQ: What is f8 pocket filter media used for?

A: F8 pocket filter media is designed for high-efficiency air filtration in HVAC systems. It effectively captures fine particles like pollen and dust. This makes it ideal for clean-air environments such as offices and hospitals.

Q: How does f6 pocket filter media differ from f8?

A: F6 pocket filter media offers good filtration for larger particles but is less efficient than f8 in trapping fine contaminants. It is cost-effective for residential applications with moderate air quality needs. F6 typically requires more frequent replacements to maintain effectiveness.

Q: Why choose f9 pocket filter media?

A: F9 pocket filter media provides superior filtration for very fine particles, such as bacteria or mold spores. It ensures high indoor air quality in critical settings like labs or manufacturing plants. Its low resistance design reduces energy consumption in air handling systems.

Q: What maintenance is needed for f5 pocket filter media?

A: F5 pocket filter media needs inspection and replacement every 3-6 months to prevent clogs. This media handles larger particles and is cost-efficient for basic filtration tasks. Always follow manufacturer guidelines for optimal performance and safety.

Q: How do f5, f6, f8, and f9 pocket filter media compare?

A: These filter media vary by filtration efficiency, with higher numbers like f9 offering finer particle capture. F5 and f6 target coarse contaminants for general use, while f8 and f9 are for sensitive environments. Select based on specific air quality standards and system requirements.

Post time: ມ.ຖ.-09-2025