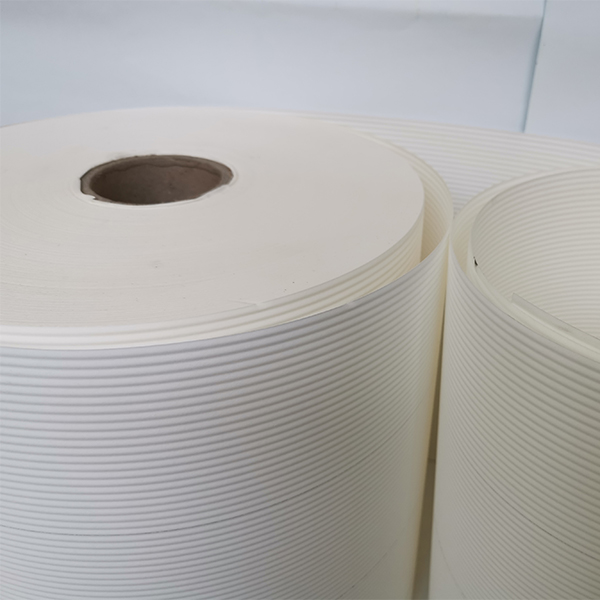

Air Filter Paper

Haec media colum facta est pulpa optimae qualitatis lignorum sicut materia rudis.

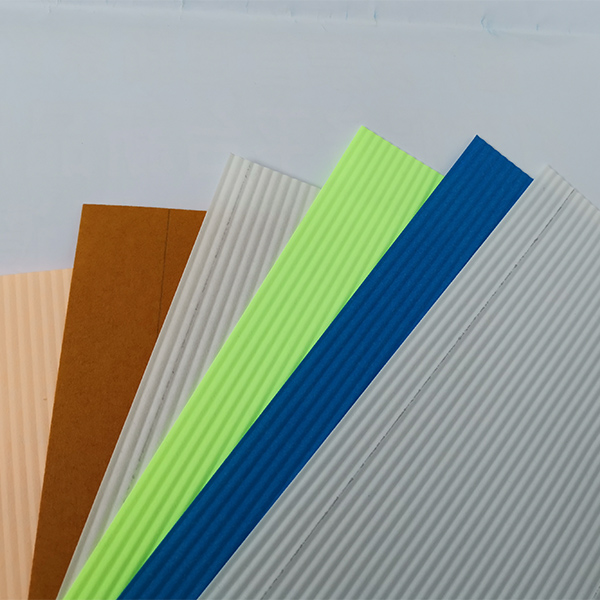

Product Feature:

Bonum caeli permeability

Princeps eliquare subtilitatem et efficientiam

Princeps pulvis tenens facultatem

Princeps rigoris resistentia rumpens

Applicatio: Aliquet varius vehicula, elit.

Product Description:

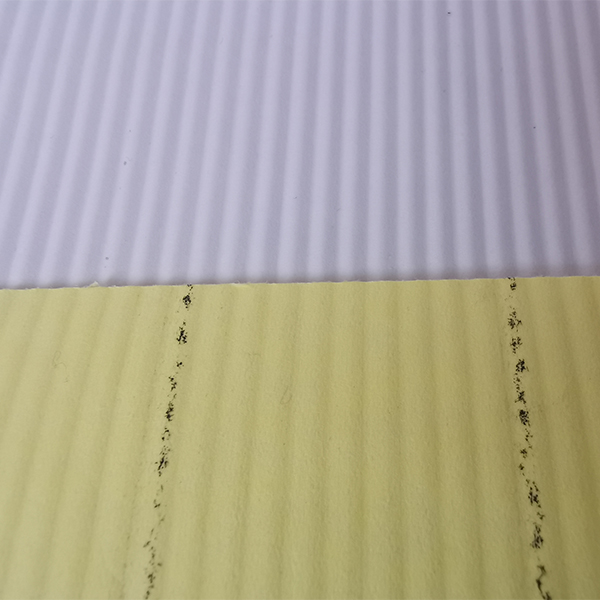

Materia cellulosa vel 80% Cellulosa + 20% Synthetica fibra

Resina Acrylic

Basic pondus 105-180g/m2

Air Permeability 110-850L/m2s

Animadverte: Aliae specificationes etiam in promptu sunt secundum exigentiam emptoris vel specimen.

Difference between air filter paper and HEPA filter media

Air filter paper and HEPA filter media serve similar purposes but differ significantly in efficiency, material composition, and applications. Air filter paper is typically made from cellulose fibers, synthetic fibers, or a blend of both, designed to capture larger particles like dust and pollen. It is commonly used in residential HVAC systems, automotive air filters, and industrial applications where moderate filtration is sufficient.

HEPA (High-Efficiency Particulate Air) filter media, on the other hand, is engineered to meet strict standards, capturing at least 99.97% of particles as small as 0.3 microns. HEPA media consists of densely packed glass fibers or synthetic materials arranged in a complex web-like structure, providing superior filtration for sensitive environments like hospitals, cleanrooms, and laboratories. While air filter paper is cost-effective for general use, HEPA media is essential for applications requiring ultra-fine particle removal.

Is air filter paper eco-friendly or recyclable?

Air filter paper can be eco-friendly depending on its materials and manufacturing process. Traditional cellulose-based filter paper is biodegradable, making it a more sustainable option compared to synthetic alternatives. However, many modern air filter papers incorporate synthetic fibers to enhance durability and filtration efficiency, which may reduce recyclability.

While used air filter paper is often contaminated with dust and pollutants, making recycling challenging, certain specialized recycling programs may process clean, unused filter paper. To minimize environmental impact, users should opt for filters made from natural fibers, dispose of them properly, or explore reusable/washable alternatives where applicable.

How to choose the right air filter paper for your application

Selecting the right air filter paper depends on several factors, including filtration efficiency, airflow resistance, and environmental conditions. First, determine the particle size you need to capture—general dust and pollen require standard filter paper, while finer particles may need a higher-efficiency media.

Next, consider the operating environment. High-humidity or high-temperature applications may require synthetic or treated filter paper to prevent degradation. For industrial settings, chemical resistance and durability are crucial. Additionally, assess the airflow resistance; a denser filter may trap more particles but could reduce system efficiency if not compatible with your equipment.