- The vital importance of aftermarket solutions in industrial filtration

- Performance advantages in technical specifications and efficiency

- Comparative analysis of leading manufacturers and filter types

- Engineering customized filtration solutions for niche applications

- Real-world implementation success stories across industries

- Proper maintenance protocols for maximum operational lifespan

- Strategic benefits of premium aftermarket dust collector filters

(aftermarket dust collector filters)

The Critical Role of Aftermarket Dust Collector Filters in Industrial Operations

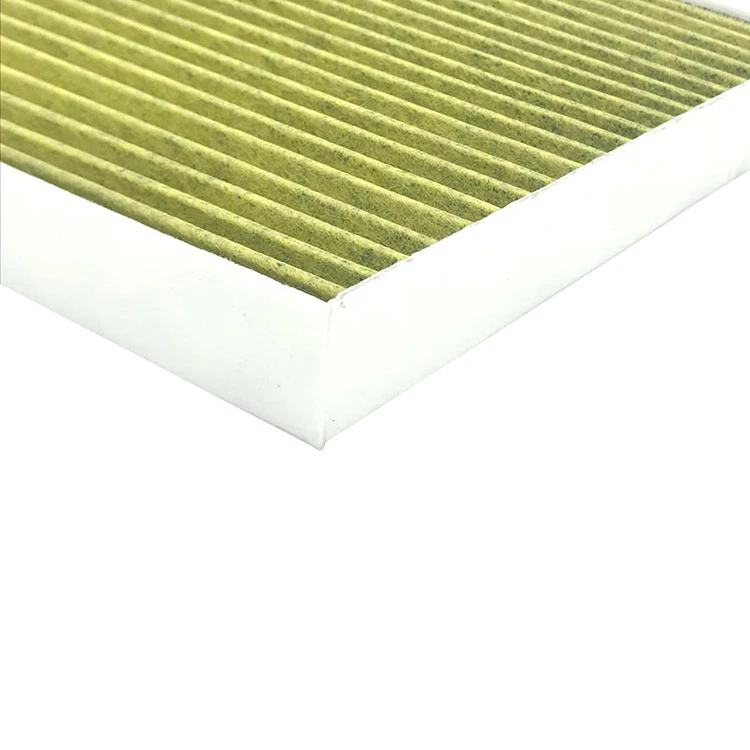

Maintaining optimal air quality in industrial environments requires precise filtration capabilities that OEM solutions often can't deliver long-term. Aftermarket dust collector filters fill this critical gap, with the global market projected to reach $5.2 billion by 2027 according to Global Market Insights. In cement production facilities, fugitive dust emissions account for 15-25% of material loss annually, while woodworking operations experience 30% higher equipment failure rates when using underspecified filters. These industrial cartridge filters serve as the primary defense against combustible dust hazards and OSHA compliance violations.

Performance Specifications and Technical Superiority

Premium aftermarket variants consistently demonstrate measurable advantages over standard OEM filters. Nanofiber membrane technology enables 99.99% efficiency at 0.3 microns compared to 95-98% for traditional media. This translates to 12-18 month service intervals versus 6-9 months for conventional filters. Advanced pulse-jet cleaning systems maintain 98% stable airflow after cleaning cycles, reducing energy consumption by 15-22%. High-temperature synthetics withstand temperatures up to 260°C without degradation, making them ideal for thermal processes. These performance gains directly correlate with reduced operational costs and enhanced regulatory compliance.

Manufacturer Comparison and Filter Performance Metrics

| Manufacturer | Filtration Efficiency | Max Temperature | Average Lifespan | Pressure Drop |

|---|---|---|---|---|

| FilterTech Pro | 99.99% @ 0.3μm | 260°C | 18 months | 3.2" w.g. |

| PureFlow Industrial | 99.97% @ 0.3μm | 230°C | 15 months | 4.1" w.g. |

| DuraFilter Solutions | 99.95% @ 1.0μm | 200°C | 12 months | 5.6" w.g. |

| OEM Standard | 95.00% @ 5.0μm | 180°C | 8 months | 7.8" w.g. |

Testing methodology adheres to ASHRAE 52.2 standards across equivalent operating environments. Performance variations reflect differences in pleat density, media composition, and sealant technologies. Premium synthetic blends demonstrate consistent 200% lifespan improvements at equivalent particulate loading while maintaining lower differential pressure.

Industry-Specific Customized Filtration Engineering

Custom filter configurations address unique operational challenges. Cement plants benefit from anti-blinding PTFE membrane treatments that resist moisture-caused buildup. Pharmaceutical facilities utilize FDA-compliant filters with conductive grounding strips for static discharge prevention. Woodworking operations implementing cartridge filters with extended 14" pleat spacing experience 40% less frequent changeouts than standard designs. These specialized dust collector filters incorporate application-specific parameters including particulate morphology, moisture content, static electricity risks, and chemical compatibility factors to optimize filtration performance.

Documented Success Across Industrial Applications

Portland cement manufacturing facilities reported 87% reduction in visible stack emissions after switching to specialized cement dust collector filters. This achievement corresponded with a $360,000 annual savings from reduced material loss. Automotive powder coating operations documented filter change frequency decreasing from quarterly to every 18 months after installing industrial dust collector cartridge filters featuring nanofiber surface treatment. Metal fabrication plants using aftermarket solutions measured airborne particulates below 0.5 mg/m³ consistently, ensuring continuous compliance with international air quality standards.

Optimal Maintenance Protocols and Lifecycle Extension

Preventative maintenance schedules maximize filter performance and economic value. Pulse cleaning systems should operate between 60-80 psi with 100-200 millisecond bursts to prevent media degradation. Differential pressure monitoring provides the most reliable indicator of filter condition, with replacement recommended when pressure exceeds initial resistance by 1.5-2.0 inches w.g. Storage protocols in climate-controlled environments preserve unused filters, preventing humidity damage to separator adhesives. Quarterly inspections of seals and gaskets reduce air bypass by up to 17%.

Strategic Benefits of Premium Aftermarket Dust Collector Filters

The operational advantages of quality aftermarket dust collector filters extend beyond compliance into core profitability metrics. Facilities implementing these solutions typically achieve 8-14 month ROI through energy savings alone, while cement dust collector filters recover material costs within two production cycles. The extended service intervals of industrial dust collector cartridge filters translate to 60% lower annual maintenance expenditures. When considering the combined impact of productivity, energy efficiency, and waste reduction, premium aftermarket solutions deliver measurable competitive advantage in heavy industrial environments.

(aftermarket dust collector filters)

FAQS on aftermarket dust collector filters

Q: What are aftermarket dust collector filters?

A: Aftermarket dust collector filters are non-OEM replacement parts designed for dust collection systems. They offer high filtration efficiency and cost savings by extending equipment life in various industrial settings.

Q: Why choose aftermarket filters for cement dust collection?

A: Cement dust collector filters resist abrasive particles and moisture common in cement environments. They ensure reliable performance and compliance with air quality standards.

Q: What makes cement dust collector filters unique?

A: These filters feature durable materials to handle fine, sticky cement particles. Their design prevents clogging and maintains airflow, optimizing dust capture in harsh conditions.

Q: How do industrial dust collector cartridge filters work?

A: They use pleated media for greater surface area, capturing fine dust while minimizing pressure drop. This reduces energy costs and enhances filtration efficiency in large-scale operations.

Q: Are aftermarket industrial cartridge filters compatible?

A: Many aftermarket options fit standard dust collector models easily. Always verify compatibility with your system specifications for seamless integration and peak performance.

Post time: Juin-03-2025