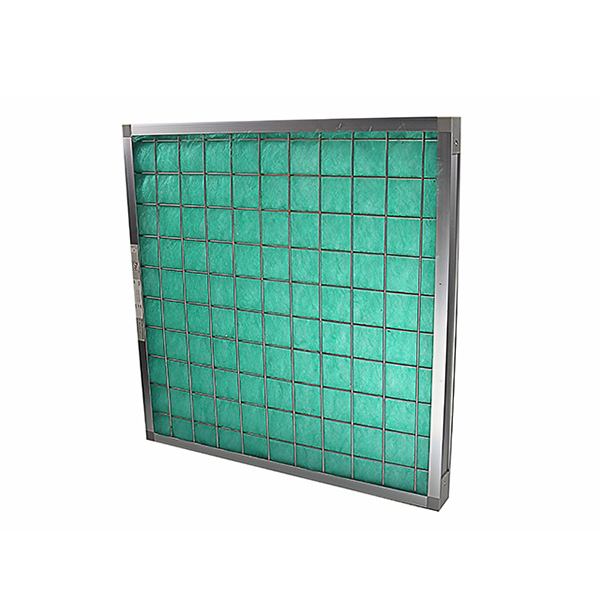

Média filtrant Paint Stop

Ce média filtrant est composé de longues fibres de verre à densité progressive. L'entrée est verte et la sortie est blanche. Autres noms : filtre de sol, média en fibre de verre, média pare-peinture.

Caractéristiques du produit :

Faible résistance initiale

Haute efficacité de séparation

Résistance aux hautes températures

Application: Cabine de peinture, filtres à plaques, filtres de sol.

Spécification:

|

Filtre Classe (EN779) |

Épaisseur ±5 mm |

Grammage ± 5 g/m2 |

Résistance initiale |

Retenue de poussière (≥ g/m2) |

Résistance à la chaleur ≥°C |

Efficacité de séparation moyenne % |

|

G3 |

50 |

250 |

10 |

3400 |

170 |

95 |

|

G3 |

60 |

260 |

10 |

3550 |

170 |

95 |

|

G4 |

100 |

330 |

10 |

3800 |

170 |

95 |

|

0,75/0,8/1,0/1,5/2,0 m x 20 m |

||||||

Remarque: D'autres spécifications sont également disponibles selon les exigences du client ou sur échantillon. Les dimensions et les conditions d'emballage peuvent être sélectionnées.

Benefits of Using Paint Stop Filter Media in Spray Booth Systems

Paint stop filter media plays a crucial role in spray booth systems by efficiently capturing overspray particles, ensuring cleaner air exhaust and protecting downstream equipment. Its high dust-holding capacity extends filter life, reducing replacement frequency and maintenance costs. The media's multi-layered design optimizes airflow while trapping paint solids, preventing clogging and maintaining consistent booth performance. Unlike standard filters, paint stop media minimizes paint carryover into exhaust systems, reducing environmental contamination and compliance risks. Its compatibility with various paint types—including water-based and solvent-based coatings—makes it versatile for automotive, industrial, and woodworking applications. By improving air quality and operational efficiency, paint stop filters enhance finish quality while lowering energy consumption in ventilation systems.

Paint Booth Exhaust Filters: Why Paint Stop Media Matters

Paint stop media is essential for spray booth exhaust systems because it effectively contains hazardous overspray before it enters the environment. Its high-efficiency filtration prevents paint particles from accumulating in ductwork and fans, reducing fire risks and equipment damage. The media's flame-retardant properties add a critical safety layer in environments with volatile solvents. Regulatory compliance often mandates effective overspray control, and paint stop filters help facilities meet EPA and OSHA standards by minimizing airborne pollutants. Additionally, by capturing paint solids before they reach exhaust systems, this media reduces cleanup costs and extends the lifespan of downstream filtration components. For shops prioritizing worker safety, environmental responsibility, and equipment protection, paint stop filters are an indispensable solution.

Fire Resistance and Safety Features of Paint Stop Filter Media

Paint stop filter media incorporates fire-resistant materials to mitigate combustion risks in spray booths where flammable solvents and aerosols are present. Treated with flame-retardant coatings or made from inherently non-combustible fibers, the media resists ignition and slows flame spread. This critical safety feature prevents filter fires from sparks or overheating equipment, protecting both workers and facilities. Unlike standard filters that may burn rapidly, fire-rated paint stop media meets industry safety standards like NFPA 33, ensuring compliance in high-risk environments. Its self-extinguishing properties reduce smoke production, limiting toxic fume hazards during incidents. For automotive refinishing and industrial coating applications, these safety enhancements make paint stop filters a vital defense against workplace fires while maintaining filtration performance.