Waraaqda Shaandheynta Hawada Muraayadaha Microfiber

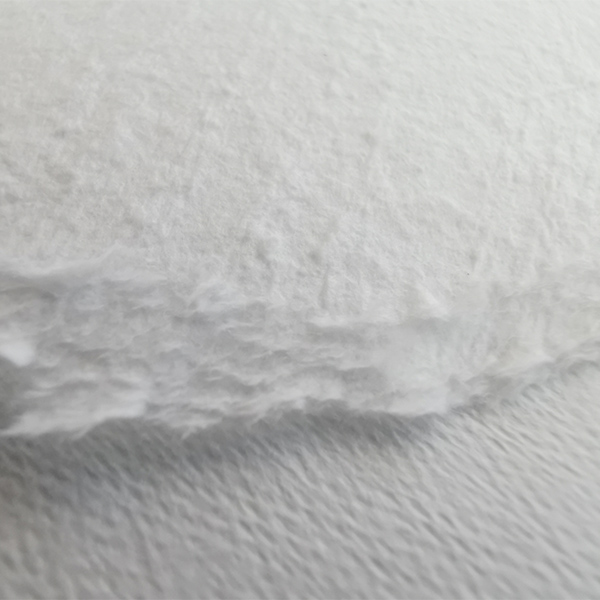

Warbaahin shaandhayntu waxay ka samaysan tahay microfiber galaas iyadoo loo marayo hab qoyan.

Sifada badeecada:

Awood haynta boodhka sare

Iska caabbinta hawada hoose

Waxtarka sifaynta sare

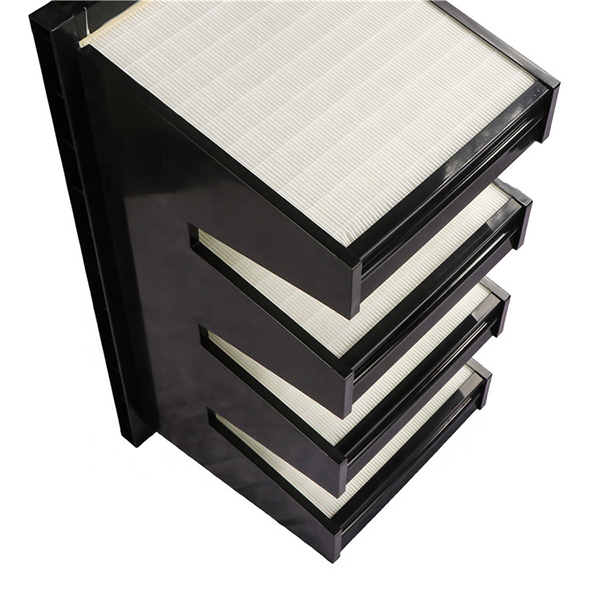

Codsiga: Qolalka Nadiifinta Warshadaha, Habaynta Cunnada, Qolalka Qalliinka ee Cusbitaalka, Ka-hortagga Dawaynta, Sifaynta Kiimikada, Sifaynta Gudaha Soo-saarka, Qalabka Qaadashada/Hawo-Qaybta, Qaadashada Hawada Gaaska, Heerkulka Sare ee Warshadaha, Nidaamka HVAC, Sifeynta Horay loogu talagalay Nidaamyada HEPA iyo HEPA, iwm.

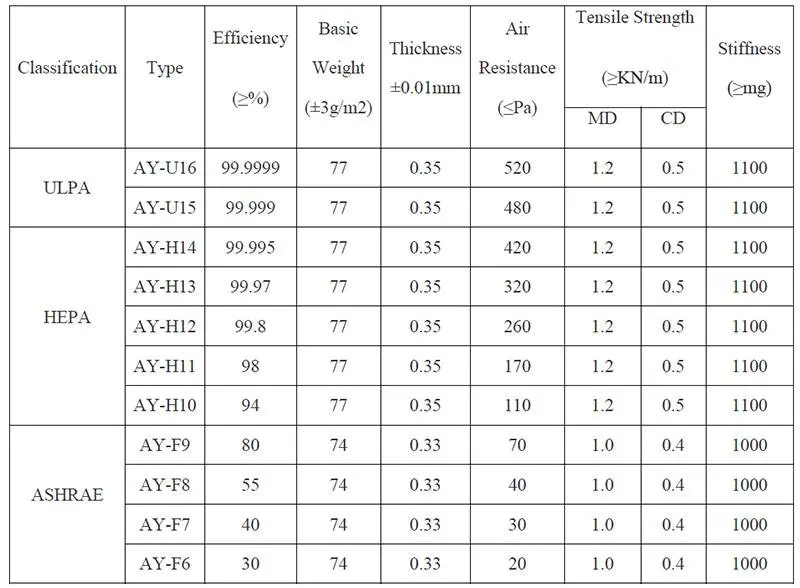

Tilmaamaha Alaabta:

Odhaah: Efficiency and Air Resistance were tested by TSI8130, 0.3µm@5.33cm/s. Special specifications can be customized as customer’s requirement.

Filtration Efficiency and Particle Retention of Glass Microfiber Paper

Glass microfiber paper delivers exceptional filtration efficiency due to its dense, non-woven fiber matrix capable of capturing particles as small as 0.3 microns with high retention rates. The random fiber arrangement creates a tortuous path for airflow, ensuring superior particle interception while maintaining low resistance. Unlike conventional filter media, glass microfiber offers near-HEPA level performance without requiring electrostatic charges, making it ideal for critical applications where consistent efficiency is paramount. Its high surface area and depth-loading characteristics allow it to hold significant contaminant loads without rapid pressure drop increases. This combination of high initial efficiency and sustained performance makes it particularly valuable in environments demanding both air purity and operational longevity, from laboratories to industrial processes.

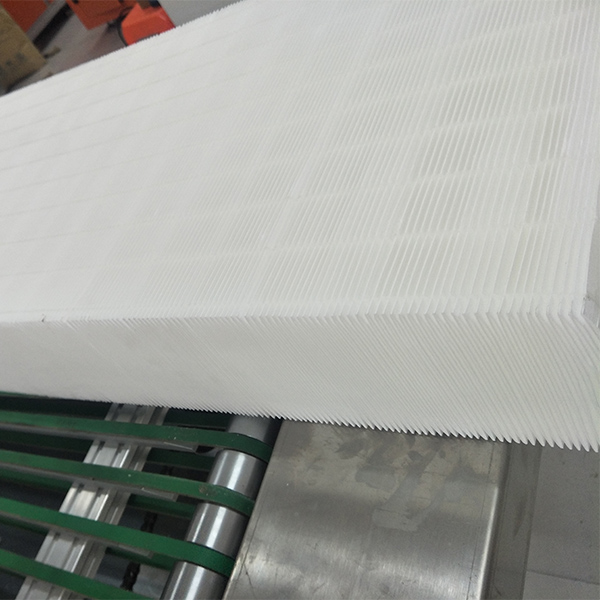

Handling, Cutting, and Storing Glass Microfiber Filter Paper Safely

Proper handling of glass microfiber paper requires precautions due to its fragile nature and potential fiber release. Always wear nitrile gloves and a particulate mask when cutting to prevent skin irritation and inhalation of loose fibers. Use sharp, clean scissors or a rotary cutter for precise edges - tearing creates uneven surfaces that compromise filtration performance. Store rolls or sheets in original packaging in a cool, dry environment below 30°C to prevent moisture absorption and fiber degradation. Avoid stacking heavy items on stored media to prevent compression damage. When installing pre-cut filters, minimize flexing or creasing which could create bypass channels. These measures preserve the media's structural integrity and filtration capabilities until deployment.

Applications of Glass Microfiber Air Filter Paper

In HVAC systems, glass microfiber paper serves as high-efficiency final filters in hospitals and commercial buildings, capturing allergens and pathogens while maintaining airflow. Cleanroom applications leverage its near-HEPA performance for semiconductor manufacturing and pharmaceutical production where sub-micron particle control is critical. The medical field utilizes sterilizable glass microfiber membranes in diagnostic devices, ventilator filters, and laboratory equipment requiring absolute particle retention. Its thermal stability allows autoclaving, while chemical inertness ensures compatibility with aggressive disinfectants. These diverse applications benefit from the media's unique combination of high filtration efficiency, durability, and purity - characteristics that synthetic alternatives often cannot match for critical air and fluid filtration needs.