Inside the 300mm HEPA Filter Paper Pleating Production Line

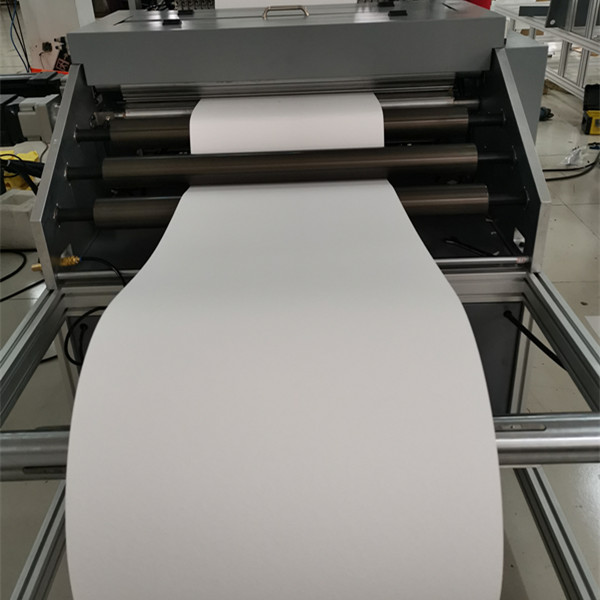

If you make motorcycle intake elements for OEM or aftermarket, you’ve probably heard whispers about the new generation of pleating lines. I spent a week on the floor with one—this bike air filter making machine—and, to be honest, it’s the first compact line I’ve seen that shifts from HEPA media to cellulose-polyester blends without drama. The headline: pleat height from 20–300 mm, no roller change-outs, just a smart speed delta between the marking roller and carry-over pin roller. It sounds small; it’s not.

What’s driving the trend?

Two things: tighter emissions targets and riders asking for longer service intervals. Dealers tell me premium foam still sells, but pleated media with nanofiber skins is inching ahead—better dust holding for off-road, lower pressure drop for street. A flexible bike air filter making machine that cuts clean, pleats evenly, and stacks reliably is becoming a competitive edge, especially for mid-size factories in Asia and Eastern Europe.

Process flow at a glance

- Unwinding & tension control: keeps media flat before slitting.

- Imported slitting unit: flat end face, no burrs—less edge shedding in ISO 5011 tests.

- Marking/bead line: hot-melt or cold mark as needed, pitch matched to pleat height.

- Carry-over pin roller: the clever bit—speed differential sets pleat height (20–300 mm) without swapping rollers.

- Pleating & forming: steady apex, minimal spring-back on multi-layer HEPA.

- Cooling/curing, counting & stacking: neat bundles, lower scrap.

Product specifications (typical)

| Model | 300mm HEPA Filter Paper Pleating Production Line |

| Max media width | ≈300 mm |

| Pleat height range | 20–300 mm (no roller change) |

| Line speed | ≈5–25 m/min, adjustable |

| Slitting accuracy | ±0.2 mm (real-world may vary) |

| Bead line pitch | ≈10–60 mm |

| Power / Air | ≈12–18 kW; 0.6–0.8 MPa |

Materials, applications, and testing

Compatible with HEPA/ULPA glass fiber, melt-blown composites, cellulose-polyester blends, PTFE-laminated media, and scrim-supported nanofiber layers. For bikes: intake panel and cone filters, snorkel prefilters, and even cabin filters on touring models. We validated against ISO 5011 (engine intake), EN 1822 (HEPA), and ISO 16890 (general air); plus IATF 16949 expectations for traceability.

Quick data from a customer pilot, dusty-road profile: initial pressure drop ≈160 Pa at 240 m³/h (panel, 35 mm pleat), dust holding ≈155 g to 200% Δp, efficiency ≥99% @ 2–3 μm (media dependent). Service life? Shops report 12–18k km for street use, 5–8k km off-road—very region-specific, I’ll admit.

Why this line works for bike filters

- Imported slitters: cleaner edges, less fiber release under ISO 5011 loading.

- Fast SKU changeover: ride from 25 mm to 80 mm pleats without retooling—just tweak speeds.

- Consistent bead lines: stabilizes pleats in high-vibration housings.

- Compact footprint, sane energy draw, honest uptime.

Vendor snapshot (indicative)

| Vendor | Price | Pleat height | Automation | Lead time | After-sales (Asia) |

|---|---|---|---|---|---|

| Anya 300mm line | Mid $ | 20–300 mm | Auto marking, counting, stacking | ≈30–45 days | Factory + remote |

| Local retrofitted line | Low $ | 20–120 mm | Semi-auto | ≈15–25 days | Limited |

| European brand | High $$$ | 10–400 mm | Full servo | ≈90–120 days | Regional hubs |

Customization, support, and real-world notes

Options: extra unwind for dual-layer feeds, anti-static kits, extended bead pitch, and recipe storage via PLC/HMI. Factory address: No.580 Gongnong Road, Shijiazhuang City 050000, Hebei, P.R. China. Many customers say the training is refreshingly practical; I’d agree—no mysterious black boxes.

Case snippets: a Pune workshop switched from foam blocks to pleated panels and cut scrap 18%. A Vietnam OEM added nanofiber media for ADV bikes and hit longer service intervals. A racing outfit in Italy—surprisingly—uses the same bike air filter making machine for pre-season batch runs, then swaps media for dyno tests.

Final thought: the real magic here isn’t just the clean slitting—though that matters—it’s the speed-coupled pleat control. It keeps your SKUs nimble and your test data consistent. Actually, that’s what lets you say yes to more custom airboxes without blowing up your setup time.

References

- ISO 5011:2014 – Inlet air cleaning equipment for internal combustion engines.

- EN 1822-1:2019 – High efficiency air filters (EPA, HEPA, ULPA).

- ISO 16890:2016 – Air filters for general ventilation.

- IATF 16949:2016 – Automotive quality management system requirements.

Post time: Oct-10-2025