Inside the G4 Polypropylene Laminate Revolution: Media Rolls Built for Real HVAC Work

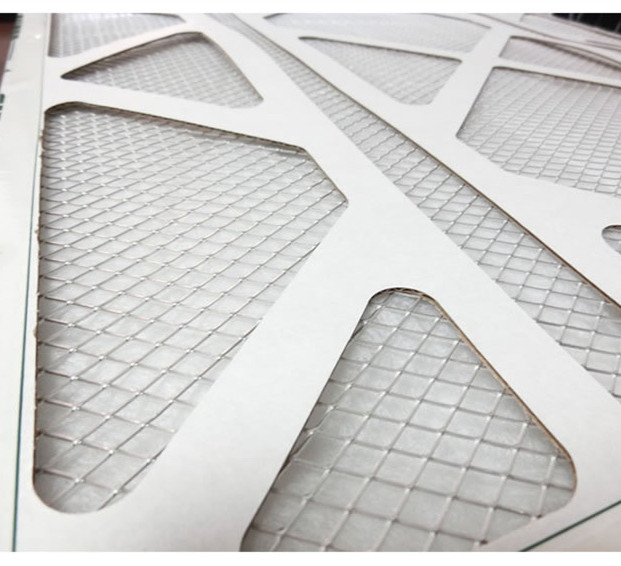

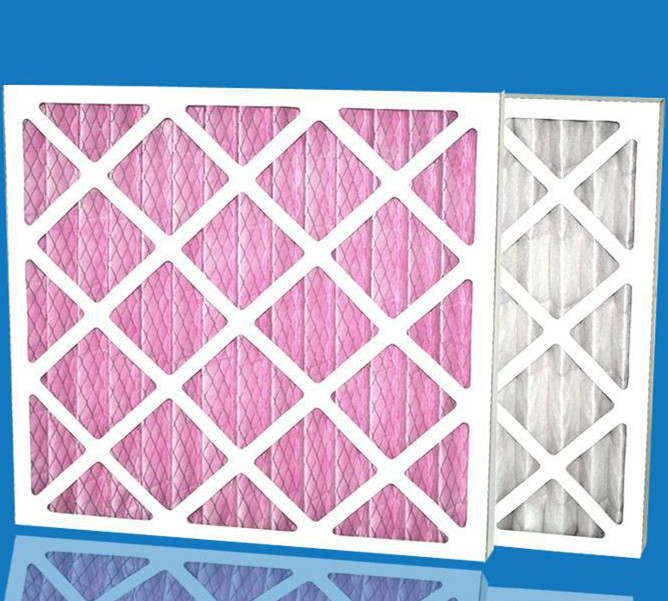

I’ve walked more mechanical rooms than I care to admit, and there’s one quiet hero that keeps showing up: synthetic air filter media rolls. The set I’m covering here is the Synthetic Polypropylene Laminate Media Roll (G4, blue/white/black), produced in Hebei, China (No.580 Gongnong Road, Shijiazhuang City 050000). It’s a mouthful, sure—but the value is simple: low initial resistance, high dust holding, and easy pleating once it’s laminated to wire mesh.

What’s trending (and why G4 isn’t going away)

Despite the buzz around higher MERV/ePM ratings, facilities still lean on synthetic air filter media rolls for prefiltration because they cut energy use, protect final filters, and keep coils clean. In fact, coarse-class media (legacy EN 779 G4) remains the standard prefilter in many AHUs, paint booths, and compressor intakes. Energy costs and maintenance windows are driving the shift toward gradient-density polypropylene that resists humidity and holds dust like a champ.

Key specs (field-friendly, not just lab talk)

| Parameter | Typical Value (≈ / around) |

|---|---|

| Classification | EN 779:2012 G4; ISO 16890: ISO Coarse (ePM10 <50%), real-world use may vary |

| Initial resistance | ≈ 35–55 Pa @ 0.5 m/s |

| Final recommended ΔP | ≈ 200 Pa (site policy dependent) |

| Dust holding capacity | High; ≈ 400–650 g/m² (test dust: ASHRAE/ISO) |

| Media | Polypropylene, gradient density (“gradually encryption” process) |

| Support | Laminated wire mesh for pleating (galv / Alu / SS options) |

| Roll sizes | Width ≈ 1.0–2.0 m; length ≈ 20–50 m; thickness ≈ 3–10 mm |

| Temp/Humidity | Up to ≈ 80°C; high RH tolerant, non-shedding |

| Colors | Blue / White / Black (layer-coded) |

How it’s made and tested

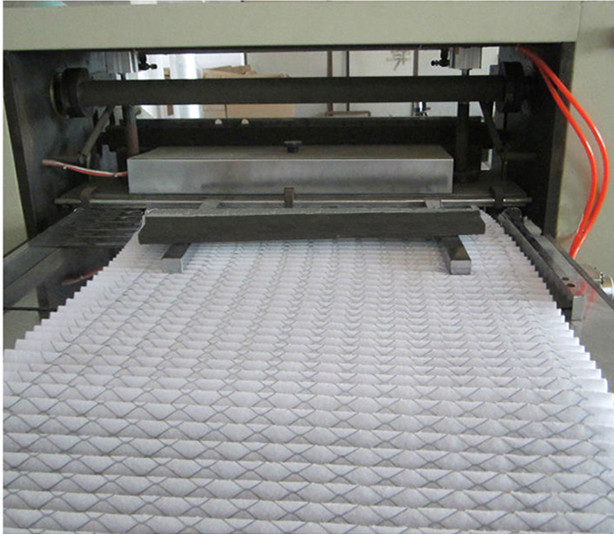

- Materials: melt-blown and/or needle-punched polypropylene layers, then laminated to wire mesh.

- Method: gradient densification (that “gradually encryption” they talk about) to trap coarse-to-fine particulates through the depth.

- Conversion: pleatable after lamination; stable pleat geometry.

- Testing: ISO 16890 (coarse fraction), legacy EN 779 G4, ASHRAE 52.2 reporting for MERV-ish context.

- Service life: around 3–9 months as a prefilter, highly dependent on dust load and changeout ΔP.

Where it works best

AHU prefilters, paint/spray booths, food & beverage, light manufacturing, commercial buildings, compressor and turbine intakes, electronics assembly. Many customers say the media’s humidity resistance beats fibrous glass in coastal sites—no sagging, less odor, and easier disposal. Honestly, that tracks with what I’ve seen.

Quick vendor comparison

| Vendor | Strengths | Watch-outs |

|---|---|---|

| Anya (Hebei, China) | Consistent G4, strong lamination, custom widths/colors, competitive lead times | MOQ may apply on special meshes |

| Generic Import A | Low price | Variable ΔP and shedding; inconsistent roll length |

| EU Brand B | Excellent documentation, tight tolerances | Higher cost; longer lead times |

Customization that actually matters

- Widths 1.0–2.0 m, lengths up to ≈ 50 m for fewer changeovers.

- Meshes: galvanized, aluminum, or stainless for pleat rigidity and corrosion environments.

- Color-coding (blue/white/black) for quick QA checks on site.

Mini case notes

• Paint booth in Bandung: swapped to synthetic air filter media rolls with mesh lamination—overspray capture improved, changeout extended ≈ 28%.

• University AHU, Texas: initial resistance shaved ≈ 12 Pa vs older media; annual fan energy down modestly (not a miracle, but it helps).

• Snack plant, Poland: operators liked the clean cut edges and “no glass itch,” as they put it.

Certifications, standards, and data

Report performance per ISO 16890 (coarse fraction) and reference legacy EN 779 G4. Some buyers still ask for ASHRAE 52.2-based MERV correlation; expect roughly MERV 5–8 equivalents depending on setup and velocity. Always validate on your rig—real-world air doesn’t read the brochure.

References

- ISO 16890:2016 (Air filters for general ventilation) – ISO

- EN 779:2012 (Particulate air filters for general ventilation) – CEN

- ASHRAE Standard 52.2-2017 (Method of Testing General Ventilation Air-Cleaning Devices) – ASHRAE

- Eurovent 4/21: Recommended filter energy rating methodology – Eurovent

Post time: Oct-16-2025