Understanding Phenolic resin filter paper: Industry Trends and Technical Foundations

In critical industrial filtration applications, the demand for high-performance and durable media is ever-increasing. Phenolic resin filter paper stands out as a superior choice, particularly in scenarios requiring exceptional chemical resistance, high temperature stability, and superior wet strength. This advanced filtration medium is integral to processes across diverse sectors, including petrochemicals, automotive, heavy machinery, and environmental protection. Industry trends indicate a growing pivot towards filter media that not only meets stringent operational demands but also contributes to greater energy efficiency and reduced maintenance overheads. Innovations in resin formulation and fiber structuring continue to push the boundaries of filtration performance, offering solutions that extend service life and improve overall system efficacy.

The global market for advanced filtration media is experiencing robust growth, driven by tightening environmental regulations and the increasing complexity of industrial fluids. Specialized media like phenolic resin filter paper are gaining prominence due to their ability to withstand aggressive chemical environments and high operating temperatures, conditions where traditional cellulose-based papers would quickly degrade. This makes them indispensable in applications involving corrosive liquids, hot oils, and various industrial solvents.

Manufacturing Process: From Fiber to Advanced Filtration Medium

The production of phenolic resin filter paper is a sophisticated multi-stage process, meticulously engineered to achieve specific performance characteristics. Unlike standard paper production, it involves precise impregnation and curing techniques to integrate the phenolic resin uniformly within the fibrous matrix. This complex manufacturing ensures the resulting media possesses high mechanical strength, thermal stability, and chemical inertness.

Detailed Process Flow:

- 1. Fiber Preparation: High-quality cellulose fibers, often blended with synthetic fibers for enhanced properties, are selected. These fibers are refined and processed into a slurry, ensuring uniform distribution and optimal length for subsequent steps. Product materials typically include bleached chemical pulp, synthetic fibers (e.g., polyester, polyamide), and specialized performance additives.

- 2. Paper Formation: The fiber slurry is then fed onto a papermaking machine (e.g., Fourdrinier or cylinder machine) where a wet web of paper is formed. The basis weight and thickness are carefully controlled at this stage to meet target specifications.

- 3. Resin Impregnation: This is a critical step. The formed paper web is saturated with a liquid phenolic resin solution. Precision control over resin concentration, viscosity, and dwell time ensures complete and uniform penetration of the resin into the fiber structure. This process, analogous to a continuous casting or coating operation, significantly enhances the paper's resistance to chemicals and moisture.

- 4. Drying and Curing: After impregnation, the paper passes through a series of drying ovens to remove solvents and initiate the curing process of the phenolic resin. Curing involves a chemical reaction (thermosetting) that transforms the liquid resin into a solid, highly cross-linked polymer. This thermal treatment, meticulously controlled for temperature profile and residence time, is crucial for developing the final mechanical strength, stiffness, heat resistance, and porosity of the advanced filter media.

- 5. Finishing and Slitting: The cured paper then undergoes calendering to achieve desired smoothness and thickness uniformity, improving pleatability. Finally, it is slit into rolls of specified widths and lengths, ready for conversion into filter elements.

- 6. Quality Control and Testing: Throughout the process, rigorous testing is conducted. This includes checks for basis weight (ISO 536), thickness (ISO 534), air permeability (ISO 5636), wet tensile strength (ISO 3781), resin content, and filtration efficiency. Adherence to international standards like ISO 16889 for multipass performance and ASTM F795 for pore size distribution ensures product reliability and consistency. The typical service life of such media in properly designed filters often exceeds 6-12 months, significantly outperforming conventional papers.

The precise control over resin impregnation and curing stages is what differentiates high-performance phenolic filter media, endowing it with its characteristic durability and effectiveness in demanding environments.

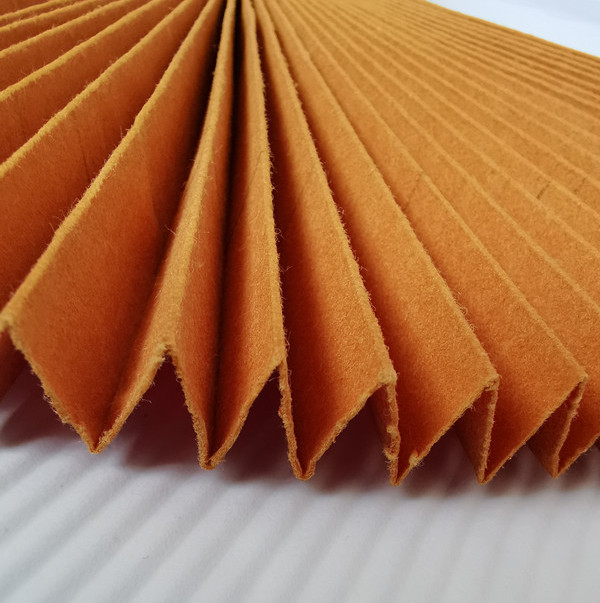

Figure 1: High-strength phenolic resin filter paper roll ready for processing.

Technical Specifications and Performance Parameters

Phenolic resin filter paper is engineered with specific technical parameters to meet the rigorous demands of industrial filtration. These parameters directly influence its effectiveness in particle retention, fluid flow, and longevity under harsh conditions.

Key Technical Specifications (Phenolic Resin Filter Paper):

| Parameter | Typical Value Range | Unit | Significance |

|---|---|---|---|

| Basis Weight | 100 – 250 | g/m² | Indicates material density and potential dirt-holding capacity, impacting structural integrity. |

| Thickness | 0.30 – 0.80 | mm | Affects pleatability and pressure drop across the medium; greater thickness often means more depth filtration. |

| Air Permeability | 50 – 200 | L/m²/s | Measure of flow resistance (porosity); crucial for predicting pressure drop and filter lifespan. |

| Resin Content | 15 – 30 | % | Higher content improves rigidity, chemical, and thermal resistance; too high can reduce permeability. |

| Wet Tensile Strength | > 150 | N/15mm | Critical for media integrity in liquid applications, preventing tearing or pleat collapse under pressure. |

| Filtration Efficiency (e.g., @ 5 micron) | > 98 | % | Particle retention capability at a specified micron rating (e.g., Beta ratio per ISO 16889). |

| Max. Operating Temperature | 130 – 160 | °C | Indicates suitability for high-temperature fluid streams without media degradation. |

| Chemical Resistance | Excellent | (acids, bases, solvents) | Resistance to degradation from various industrial chemicals, ensuring filter longevity. |

These specifications highlight the robust nature of phenolic filter media, making it suitable for demanding applications where reliability and performance are paramount. The high wet tensile strength, in particular, prevents media breakdown under differential pressure, a common failure point for untreated filter papers, while consistent pore distribution ensures high dirt-holding capacity and prolonged service intervals.

Application Scenarios and Technical Advantages

Phenolic resin filter paper is not merely a filter medium; it's an engineered solution for critical filtration challenges across diverse heavy industries. Its unique properties provide significant technical advantages over conventional filter papers.

Target Industries and Typical Applications:

- Petrochemical: Filtration of fuels (e.g., diesel, gasoline), lubricating oils, hydraulic fluids, and various aggressive chemical process streams. The exceptional corrosion resistance and high-temperature stability are critical here for protecting sensitive equipment.

- Metallurgy: Cleaning of rolling oils, quenching oils, and coolants in metalworking processes, preventing abrasive wear on precision machinery and improving surface finish of products.

- Water Supply & Drainage: Pre-filtration and primary filtration in industrial wastewater treatment, and filtration of process water in sectors where chemical dosing or challenging water compositions are present. Its robust nature handles fluctuating conditions effectively.

- Automotive & Heavy Equipment: Used extensively in engine oil filters, fuel filters, and hydraulic filters where consistent performance under vibration, pressure pulses, and temperature extremes (both hot and cold starts) is required to protect vital engine and hydraulic components.

- Power Generation: Filtration of turbine oils, transformer oils, and other critical lubricants in power plants, enhancing equipment longevity and reliability of power generation assets.

Demonstrated Advantages:

- Corrosion Resistance: The phenolic resin binder provides exceptional resistance to a wide range of acids, alkalis, and organic solvents. This makes it ideally suited for chemically aggressive fluid streams found in chemical processing and petrochemical industries, leading to extended filter life and reduced material degradation.

- High-Temperature Stability: Capable of operating effectively at continuous temperatures up to 160°C and even higher for short bursts, significantly outperforming untreated cellulose papers which typically degrade around 100-120°C. This ensures filtration integrity in hot oil, engine coolant, and high-temperature process fluid applications.

- Enhanced Wet Strength: The resin impregnation dramatically increases the paper's strength when wet, making it resistant to blow-outs, tearing, and fiber migration into the clean fluid stream, even under high differential pressures and fluctuating flow conditions. This robustness is critical for reliable performance in liquid filtration.

- Superior Particle Retention: The rigid structure formed by the cured resin provides a stable pore matrix, leading to consistent micron ratings and high filtration efficiency throughout the filter's service life. This stable pore structure prevents particle unloading (where trapped particles are released) under varying pressures.

- Extended Service Life & Energy Saving: Due to its robust construction and resistance to degradation, filters made with phenolic resin filter paper typically have a longer operational lifespan. This reduces filter change-out frequency, decreases associated labor and disposal costs, and minimizes operational downtime. By maintaining optimal flow rates for longer periods, they also contribute to reduced energy consumption in pumping systems.

Figure 2: Precision slitting of phenolic resin filter paper for various filter element sizes.

Vendor Comparison and Customized Solutions

Selecting the right supplier for phenolic filter media is critical for ensuring consistent quality and optimal performance in demanding industrial applications. While many vendors offer filter media, key differentiators lie in their manufacturing precision, quality control, and ability to provide tailored solutions.

Key Differentiators in Vendor Selection:

| Feature | High-Quality Vendor (e.g., Anya Filter Media) | Standard Vendor |

|---|---|---|

| Resin Formulation | Proprietary, optimized for specific application performance (e.g., higher temperature, specific chemical resistance). | Generic, standard phenolic resin, potentially less specialized. |

| Manufacturing Precision | Automated, tightly controlled impregnation and curing process ensuring uniform resin distribution and consistency. | Manual or less precise control, leading to variability in resin content and curing, affecting performance. |

| Quality Control | ISO 9001 certified, comprehensive in-process and final product testing (wet strength, permeability, efficiency, burst strength). | Basic QC, less frequent or comprehensive testing, higher risk of batch variation. |

| Customization Capabilities | Offers tailor-made solutions for basis weight, thickness, resin type, and pore size distribution to match exact needs. | Limited standard product range, minimal or no customization options. |

| Technical Support | Dedicated technical team, application engineering support, comprehensive performance data, and consultation. | Basic sales support, limited technical guidance or engineering expertise. |

| Service Life & Reliability | Longer service life, consistent filtration performance, reduced operational downtime, and lower total cost of ownership. | Potentially shorter life, inconsistent performance, higher risk of premature failure and unexpected costs. |

Customized Solutions:

Leading manufacturers understand that off-the-shelf solutions may not always be sufficient for highly specialized industrial processes. Customization options for phenolic filter media include:

- Tailored Basis Weight and Thickness: To optimize dirt-holding capacity and pressure drop for specific flow rates and desired pleat configurations.

- Adjusted Resin Content: To fine-tune stiffness, wet strength, and chemical resistance for extreme applications or specific fluid chemistries.

- Modified Fiber Blends: Incorporating synthetic fibers (e.g., polyester, fiberglass) or natural fibers to enhance specific properties like burst strength, chemical compatibility, or filtration efficiency.

- Specific Micron Ratings: Developing media with precise pore size distributions for ultra-fine filtration (e.g., 0.5 µm) or coarser filtration requirements, often verified by poreometry.

- Specialty Treatments: Including flame retardant additives, anti-microbial treatments, or oleophobic/hydrophobic coatings for niche and challenging applications.

Figure 3: Quality inspection of phenolic resin filter paper for uniform impregnation.

Application Case Studies & Customer Trust

Real-world applications demonstrate the unparalleled performance and reliability of phenolic filter media in challenging industrial environments. Our commitment to quality and customer satisfaction is built on proven results.

Case Study 1: Petrochemical Hydraulic System Filtration

A major petrochemical facility faced recurring issues with hydraulic system downtime due to contamination and premature degradation of standard cellulose filters, exacerbated by high operating temperatures and aggressive hydraulic fluids. Upon switching to high-temperature phenolic filter media, the facility observed:

- 30% Extension in Filter Service Life: Reducing filter change-outs from quarterly to bi-annually, resulting in significant operational savings.

- 15% Reduction in Maintenance Costs: Lowering labor, filter element purchase, and disposal expenses.

- Improved Fluid Cleanliness (ISO 4406 cleanliness codes): Consistent particle removal led to a 2-point improvement in fluid cleanliness (e.g., from 18/16/13 to 16/14/11), directly extending the lifespan of critical hydraulic components like pumps and valves.

Customer Feedback: "The durability of the phenolic filter media has significantly improved our operational efficiency. We've seen a tangible impact on uptime and a noticeable reduction in hydraulic system wear, confirming the material's superior performance in our demanding environment."

Case Study 2: Automotive Engine Oil Filtration for Heavy-Duty Diesel

An OEM of heavy-duty diesel engines required a filter medium capable of handling extended oil drain intervals and the extreme conditions of modern engine lubricants (high temperature, high additive load, high soot content). Conventional filters struggled with thermal degradation and media collapse under high differential pressures. By integrating specially formulated phenolic filter media:

- Achieved 20,000 km Extended Oil Drain Interval: Exceeding industry standards and competitive offerings by maintaining filtration efficiency and media integrity for longer periods.

- Maintained Filtration Efficiency: Consistent particle capture (e.g., Beta 2000 at 10 microns) even towards the end of the extended service life, effectively preventing engine wear and maintaining oil quality.

- Enhanced Structural Integrity: Zero instances of media pleat collapse or tearing reported during extensive field testing, validating the high wet strength and thermal stability of the media.

Authoritativeness and Certifications: Our manufacturing processes are ISO 9001:2015 certified, ensuring consistent quality management from raw material sourcing to final product delivery. We conduct performance testing according to recognized industry standards such as ISO 16889 (Multipass Filter Performance), ASTM F795 (Pore Size Distribution), and SAE J1858 (Engine Oil Filter Performance). Our trusted partnerships with global leaders in filtration technology and heavy industry span over 15 years, a testament to our expertise and reliability in supplying critical filter media solutions.

Figure 4: Automated production line for precision coating of resin filter paper.

FAQs, Lead Time, Warranty, and Support

We believe in transparency and providing comprehensive support to our clients. Here are answers to common questions and details regarding our operational commitments.

Frequently Asked Questions (FAQs):

-

Q: What makes phenolic resin filter paper superior to standard cellulose paper?

A: Our phenolic filter media offers significantly higher wet strength, superior resistance to a wide range of chemicals (acids, bases, solvents), and greater thermal stability (up to 160°C). These properties ensure longer service life, consistent filtration performance, and enhanced reliability in harsh industrial environments where standard cellulose would rapidly degrade or fail. -

Q: Can your filter media be customized for specific applications?

A: Absolutely. We offer extensive customization options, including variations in basis weight, thickness, resin content, fiber blend, and micron rating. Our experienced engineering team works closely with clients to develop media that perfectly matches their specific operational requirements and challenging fluid conditions. -

Q: What are the typical lead times for custom orders?

A: Lead times for custom orders of our specialized filter media typically range from 4 to 8 weeks, depending on the complexity of the customization, required testing, and order volume. Standard product configurations generally ship within 2-4 weeks. We prioritize efficient production planning and logistics to meet client schedules. -

Q: How do you ensure the quality and consistency of your products?

A: Our quality management system is ISO 9001:2015 certified, and we adhere to strict quality control protocols at every stage of manufacturing. We implement stringent in-process quality control measures and conduct comprehensive final product testing (e.g., air permeability, wet tensile strength, resin content, filtration efficiency, pore size distribution) according to international standards such as ISO and ASTM. Every batch is rigorously inspected and documented before shipment to ensure batch-to-batch consistency.

Lead Time & Fulfillment:

We maintain a robust inventory of critical raw materials and utilize optimized production lines to ensure timely and reliable delivery of our products.

- Standard Products: Typically 2-4 weeks from confirmed order receipt.

- Customized Solutions: 4-8 weeks, depending on the complexity of specifications, material availability, and required validation testing. Expedited options may be available upon request for urgent requirements.

Warranty Commitments:

All our phenolic filter media products come with a 1-year warranty against manufacturing defects, provided they are stored, handled, and used under recommended conditions and within specified operating parameters. This commitment underscores our unwavering confidence in the quality, durability, and performance of our filtration media.

Customer Support:

Our dedicated and highly experienced technical support team is available to assist clients with product selection, application challenges, and performance optimization. We offer comprehensive support, including:

- Technical Consultation: Expert guidance and data-driven recommendations on integrating our filter media into your existing or new filtration systems.

- Application Engineering: Collaborative development of custom solutions, including feasibility studies and prototype testing, to precisely meet unique industrial requirements.

- After-Sales Support: Prompt and responsive assistance with any product-related queries, performance monitoring, or issues post-purchase to ensure continuous operational excellence.

Conclusion

Phenolic resin filter paper represents a critical advancement in industrial filtration technology, offering unmatched durability, chemical resistance, and thermal stability. Its widespread adoption across petrochemical, automotive, and heavy equipment sectors underscores its pivotal role in enhancing operational efficiency, extending component longevity, and reducing overall maintenance costs. By leveraging precise manufacturing processes and stringent quality control, leading manufacturers deliver bespoke filtration solutions that address the most demanding industrial challenges. As industries continue to evolve, the strategic choice of high-performance filter media like phenolic resin-impregnated paper will remain a cornerstone for achieving superior fluid cleanliness and sustainable operational excellence. Partnering with an expert supplier ensures access to cutting-edge materials and dedicated support, vital for maintaining competitive advantage and meeting stringent regulatory standards.

References

- 1. ISO 16889: Hydraulic fluid power – Filters – Multi-pass method for evaluating filtration performance of a filter element. International Organization for Standardization.

- 2. ASTM F795: Standard Practice for Determining the Performance of a Filter Medium. ASTM International.

- 3. SAE J1858: Standard for Oil Filter Test Procedure for Full-Flow Oil Filters on Diesel Engines. Society of Automotive Engineers.

- 4. U.S. Environmental Protection Agency. (2023). Industrial Wastewater Treatment Technologies. EPA.gov.

- 5. Filtration and Separation Magazine. (2021). Advances in Resin-Impregnated Filter Media for High-Performance Applications. Elsevier Publications.

- 6. Wankhede, V. (2018). Filtration in Oil and Gas Industry. Petrochemical Engineering Department.

Post time: Sep-19-2025