Introduction to Glass Fiber Filtration Technology

In the realm of advanced air and liquid filtration, the glass fiber filter stands as a cornerstone technology. Renowned for its exceptional performance characteristics, these filters are integral to maintaining air quality, safeguarding sensitive processes, and ensuring product purity across a myriad of industrial applications. Primarily composed of microfine glass fibers, this filter media is engineered to capture sub-micron particles with unparalleled efficiency, making it indispensable where stringent contamination control is paramount. Our focus here is to delve into the intricate aspects of glass fiber filtration, exploring its manufacturing, technical superiority, diverse applications, and the comprehensive solutions it offers to B2B clients.

Industry Trends and Market Dynamics for Glass Fiber Filter Media

The market for glass fiber filter media is experiencing robust growth, driven by escalating global awareness of air quality, more stringent environmental regulations, and advancements in industrial processes demanding higher levels of purity. Key trends include:

- Increasing Demand for HEPA/ULPA Filtration: Industries such as pharmaceuticals, microelectronics, and healthcare facilities are continuously upgrading their cleanroom standards, necessitating the use of high-efficiency particulate air (HEPA) and ultra-low penetration air (ULPA) filters, where glass microfiber is the primary media.

- Sustainability and Energy Efficiency: There's a growing emphasis on filters that offer lower pressure drop, leading to significant energy savings in HVAC systems. Innovations in glass fiber manufacturing are focusing on optimizing fiber structure for improved airflow with sustained efficiency.

- Advanced Materials Science: Research into blending glass fibers with other synthetic or natural fibers to create composite media for enhanced performance (e.g., higher dust holding capacity, improved pleatability, or specific chemical resistance) is prevalent.

- Regulatory Compliance: Stricter global standards for emissions (e.g., Euro 6/7 for automotive, IMO 2020 for marine) and indoor air quality are pushing manufacturers to develop more effective and durable glass fiber filter solutions.

Projections indicate a steady market expansion, with the global air filtration market size, heavily reliant on glass fiber filter media, expected to reach approximately USD 24 billion by 2027, growing at a CAGR of 6-8% from 2020. This growth underscores the critical role of glass fiber technology in industrial health, safety, and operational efficiency.

Manufacturing Process Flow of Glass Microfiber Air Filter Paper

The production of high-quality glass fiber filter media, specifically glass microfiber air filter paper, involves a meticulously controlled wet-laid papermaking process. This ensures consistent fiber distribution, uniform pore size, and optimal filtration performance. The general process flow is as follows:

Materials and Preparation:

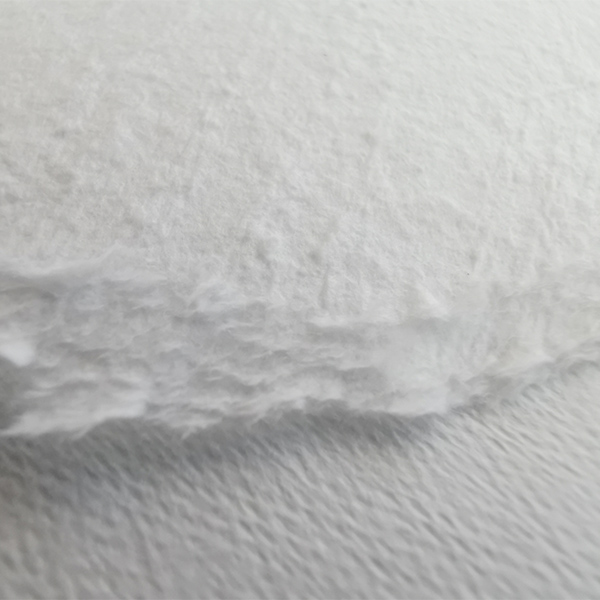

- Raw Materials: Primarily composed of borosilicate glass fibers (E-glass, C-glass), chosen for their chemical resistance, high temperature stability, and ability to be drawn into extremely fine diameters (typically 0.1 to 10 micrometers). Small amounts of organic binders (e.g., acrylic, styrene-butadiene rubber) are used to provide mechanical strength and pleatability, along with sizing agents.

- Fiber Dispersion: The glass microfibers are carefully dispersed in an aqueous solution, often with specific dispersing agents to prevent agglomeration and ensure individual fiber separation. This creates a homogeneous slurry.

Manufacturing Process Steps (Wet-Laid Papermaking):

- Slurry Preparation: The precisely measured glass fibers, binders, and additives are mixed in water to form a uniform slurry in large vats. This step is critical for controlling the final filter characteristics.

- Web Formation (Casting): The slurry is pumped onto a continuous wire mesh screen (similar to traditional papermaking machines), where water is drained through gravity and vacuum suction. As water is removed, the intertwined glass fibers form a delicate, continuous web. The uniformity of this web directly influences filtration efficiency and pressure drop.

- Binder Application & Curing: The wet web is then passed through a binder impregnation station, where a carefully formulated binder solution is applied. Subsequently, the web enters a drying and curing oven. Heat activates the binder, permanently bonding the glass fibers together, providing mechanical strength and rigidity to the filter paper. This "forging" process locks the fiber matrix.

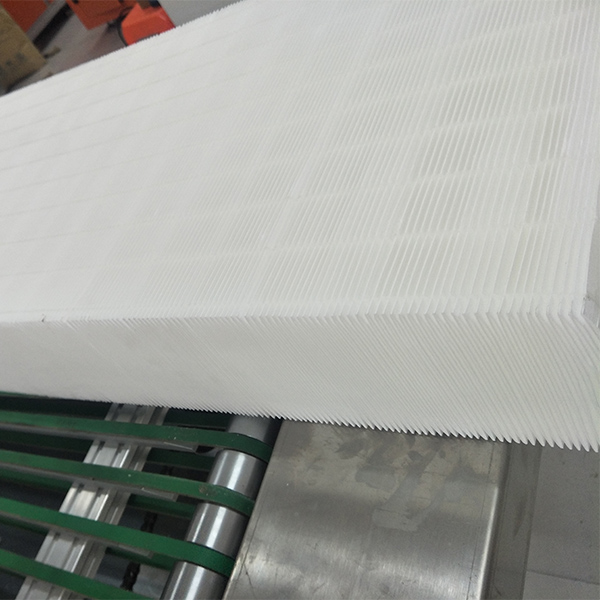

- Calendering & Finishing: Depending on the desired thickness and surface finish, the dried paper may pass through calender rollers to achieve precise caliper control and smoothness. CNC machining processes are employed for precision slitting and winding into rolls of specified widths and lengths.

- Quality Control & Testing: Throughout the process, rigorous testing is conducted. This includes measuring basis weight, thickness, air permeability, tensile strength, and most critically, filtration efficiency and pressure drop.

Testing Standards and Service Life:

Our glass fiber filter media adheres to international testing standards, ensuring consistent and reliable performance:

- ISO 2943 (Filtration Elements): For material compatibility and integrity.

- ISO 16889 (Multi-pass test): For filtration performance including efficiency and dirt-holding capacity.

- EN 1822 (HEPA and ULPA filters): Specifically for determining filtration efficiency for sub-micron particles, crucial for air filter paper.

- ASTM D570 (Water Absorption): Ensuring media integrity in humid conditions.

The service life of glass fiber filter media varies significantly based on application, particle loading, and operating conditions. Typically, in HVAC applications, filters can last from 6 months to 2 years, while in critical cleanroom environments, HEPA/ULPA filters may be replaced based on pressure drop monitoring or scheduled maintenance cycles, often annually or bi-annually. Our media is engineered for extended service life, reducing total cost of ownership.

Technical Specifications and Performance Parameters

Our Glass Microfiber Air Filter Paper is engineered to meet the stringent demands of high-performance filtration. The following table provides typical technical specifications for our range of products, demonstrating versatility across various efficiency requirements (e.g., HEPA H10 to ULPA U17 according to EN 1822 standard).

Typical Product Specification Table: Glass Microfiber Air Filter Paper

| Parameter | Unit | Typical Range (HEPA/ULPA Grades) | Test Standard |

|---|---|---|---|

| Basis Weight | g/m² | 40 - 200 | ISO 536 |

| Thickness | mm | 0.20 - 0.80 | ISO 534 |

| Air Permeability (at 200 Pa) | L/m²/s | 150 - 600 | ISO 9237 |

| Tensile Strength (MD/CD) | N/15mm | > 20 / > 10 | ISO 1924-2 |

| Bursting Strength | kPa | > 150 | ISO 2758 |

| Filtration Efficiency (MPPS) | % | 99.95 - 99.999995 | EN 1822-3 |

| Pressure Drop (at 5.3 cm/s) | Pa | 100 - 250 | EN 1822-3 |

| Max. Operating Temp. | °C | 250 - 450 (depending on binder) | Manufacturer Test |

The selection of the appropriate glass fiber filter grade depends on the specific application's particle removal requirements, airflow rates, and operating conditions. Our technical team assists clients in identifying the optimal media for their filtration systems, ensuring peak performance and compliance.

Application Scenarios and Technical Advantages

The versatility and superior performance of glass microfiber filter paper make it indispensable across a broad spectrum of industries, offering distinct technical advantages:

Target Industries and Typical Applications:

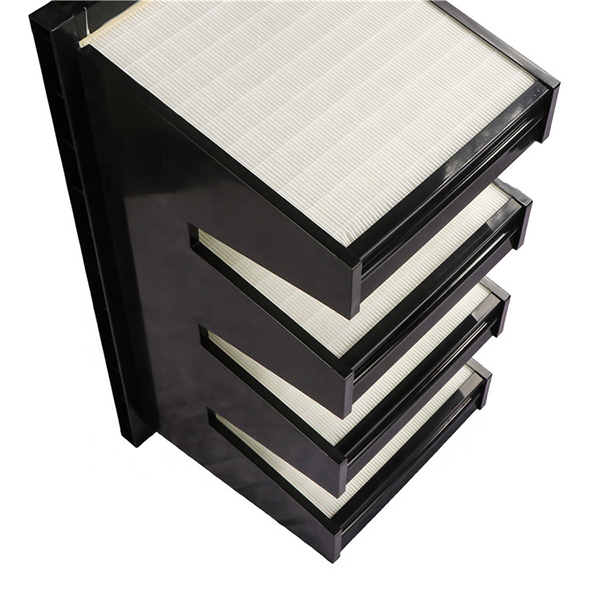

- Pharmaceuticals & Biotechnology: Crucial for cleanroom HVAC systems (HEPA/ULPA filters), sterile air supply in aseptic processing, and protection of sensitive laboratory equipment. Ensures compliance with GMP standards by preventing airborne contamination.

- Micro-electronics & Semiconductor Manufacturing: Ultra-clean environments are paramount. Glass fiber filters are used in wafer fabrication facilities, hard drive assembly, and display manufacturing to achieve ISO Class 1-5 cleanliness levels, preventing defects caused by airborne particles.

- Healthcare & Hospitals: Air purification in operating theaters, isolation wards, and laboratories to prevent nosocomial infections and protect immunocompromised patients.

- Nuclear Industry: Filtration of radioactive aerosols and particulate matter in ventilation systems for safety and environmental protection.

- Food & Beverage: Filtration of intake air for processing areas, preventing microbial contamination and ensuring product safety and shelf-life.

- HVAC Systems (Commercial & Industrial): High-efficiency pre-filtration and final filtration in commercial buildings, data centers, and industrial ventilation systems to improve indoor air quality, protect sensitive machinery, and reduce energy consumption.

- Petrochemical & Chemical Processing: Used in gas turbine intake filters and process air filtration to protect critical machinery from corrosive particles and ensure process purity.

- Metallurgy: Filtration of dust and fumes in smelters and foundries to protect workers and equipment, and comply with emission regulations.

Key Technical Advantages:

- High Filtration Efficiency: Designed to capture sub-micron particles (0.1-0.3 µm) with efficiencies up to 99.999995% (ULPA U17), critical for cleanroom applications. This is achieved through a dense, intricate network of fine glass fibers, leveraging mechanisms like impaction, interception, and diffusion.

- Low Pressure Drop: Optimized fiber structure ensures efficient airflow with minimal resistance, directly translating to significant energy savings for fan motors in HVAC and industrial ventilation systems. This "energy saving" aspect is a major ROI driver for clients.

- Chemical Resistance: Borosilicate glass fibers offer inherent resistance to a wide range of acids, alkalis, and organic solvents, making them suitable for use in chemically aggressive environments. This "corrosion resistance" extends filter life and reliability.

- High Temperature Stability: Glass microfiber media can withstand high operating temperatures (up to 450°C, depending on the binder), enabling its use in applications where other media would degrade.

- High Dust Holding Capacity: The deep-bed filtration mechanism allows for substantial particle loading before filter change-out, extending service life and reducing maintenance frequency.

- Dimensional Stability: Maintains structural integrity under varying conditions of humidity and temperature, crucial for consistent performance.

- Flame Retardancy: Glass is naturally non-combustible, contributing to fire safety in critical installations.

These advantages underscore why glass fiber filter media remains the preferred choice for demanding filtration tasks where purity, reliability, and cost-effectiveness are non-negotiable.

Vendor Comparison and Customized Solutions

Selecting the right supplier for glass fiber filter media is critical for ensuring consistent quality, optimal performance, and supply chain reliability. While many manufacturers offer similar products, key differentiators often lie in material quality, manufacturing precision, technical support, and customization capabilities.

Key Considerations for Vendor Selection:

- Manufacturing Expertise: Look for vendors with deep experience in wet-laid process technology and stringent quality control.

- Certifications: Verify ISO 9001 quality management, EN 1822 compliance, and other relevant industry certifications (e.g., FDA compliance for certain applications).

- Technical Support: Access to expert engineers who can provide guidance on filter selection, system integration, and troubleshooting.

- Customization Capabilities: The ability to tailor media parameters (basis weight, thickness, efficiency, binder type) to specific application requirements.

- Supply Chain Reliability: Consistent product availability, lead times, and logistical support, especially for international clients.

Example Comparison: Standard vs. High-Performance Glass Fiber Media

| Feature/Parameter | Standard HEPA Grade Media | Advanced ULPA Grade Media |

|---|---|---|

| Efficiency (EN 1822) | H13 (99.95% at MPPS) | U15-U17 (99.9995% - 99.999995% at MPPS) |

| Fiber Diameter | ~0.8 - 1.5 µm | ~0.1 - 0.5 µm |

| Pressure Drop (Initial) | Moderate | Lower (for equivalent efficiency at target flow) |

| Binder Type | Standard acrylic/SBR | Advanced synthetic, low outgassing, high-temp resistant |

| Target Applications | General HVAC, industrial cleanrooms, pre-filtration | Semiconductor, pharmaceutical, biosafety, critical cleanrooms |

| Cost | Moderate | Higher (justified by performance) |

Customized Solutions:

Recognizing that off-the-shelf solutions may not always meet unique client requirements, we specialize in providing customized glass fiber filter media. This includes:

- Tailored Efficiency & Pressure Drop: Adjusting fiber composition and density to achieve specific filtration efficiency at desired pressure drops for energy optimization.

- Specialized Binders: Developing media with high-temperature resistant binders, chemically inert binders, or binders suitable for food-grade contact (FDA compliant).

- Custom Widths & Lengths: Supplying media in precise dimensions to integrate seamlessly into existing or new filter manufacturing lines.

- Pleatability & Mechanical Strength: Enhancing the media's ability to be pleated into various configurations without compromising integrity, crucial for maximizing surface area and dust holding capacity in finished filters.

- Antimicrobial Treatments: Incorporating additives for applications requiring prevention of microbial growth on the filter media itself.

Our dedicated R&D team works closely with clients to understand their specific challenges and develop proprietary glass fiber filter solutions that deliver superior performance and value.

Application Case Studies and Customer Testimonials

Real-world application demonstrates the tangible benefits derived from deploying high-quality glass fiber filter media. Our commitment to excellence is reflected in the success of our partners across diverse industries.

Case Study 1: Pharmaceutical Cleanroom Upgrade

- Client: A leading global pharmaceutical manufacturer.

- Challenge: Maintaining ISO Class 5 air cleanliness in a new sterile filling line while reducing operational energy costs associated with high-pressure drop filters.

- Solution: We supplied custom-designed glass microfiber air filter paper, achieving EN 1822 H14 efficiency with an optimized fiber structure for significantly lower initial pressure drop. The media was used to manufacture custom HEPA filters for their HVAC system.

- Results: The client achieved consistent ISO Class 5 certification for their cleanroom. Energy consumption related to air handling units decreased by 18% annually, translating to substantial operational savings. Filter replacement cycles were extended by 6 months due to improved dust holding capacity, further reducing maintenance costs.

- Client Feedback: "The customized glass fiber media not only met our stringent purity requirements but also provided unexpected energy efficiencies, directly impacting our bottom line."

Case Study 2: Semiconductor Manufacturing Facility

- Client: A major semiconductor wafer fabrication plant.

- Challenge: Eliminating ultra-fine particulate contamination (down to 0.1 µm) in critical process areas to minimize wafer defects, which directly impact yield rates.

- Solution: We developed an ultra-high efficiency ULPA grade glass microfiber filter media (EN 1822 U16 equivalent) with advanced binder technology to prevent any outgassing that could affect sensitive electronic components.

- Results: The deployment of filters made with our specialized media led to a documented 7% reduction in wafer defect rates attributable to airborne particulates. This improvement had a multi-million dollar impact on annual production yields.

- Client Feedback: "The precision of their glass fiber filter media is unmatched. It has been instrumental in improving our yield and maintaining our competitive edge in a highly demanding industry."

Frequently Asked Questions (FAQ)

Q1: What is the primary difference between glass fiber filter media and synthetic filter media?

A1: Glass fiber filter media, particularly microfiber glass, excels in achieving extremely high efficiencies (HEPA/ULPA) at sub-micron particle sizes due to the very fine, randomly oriented fibers and their inherent electrostatic properties. Synthetic media (e.g., polypropylene, polyester) typically offers good efficiency for larger particles and can be more robust, but generally struggles to achieve the same efficiency levels as glass fiber at the MPPS (Most Penetrating Particle Size) without significantly higher pressure drops. Glass fiber also offers superior high-temperature and chemical resistance.

Q2: Are your glass fiber filters suitable for cleanroom environments?

A2: Absolutely. Our Glass Microfiber Air Filter Paper is specifically designed and manufactured to meet and exceed the stringent requirements for HEPA (H10-H14) and ULPA (U15-U17) filtration, essential for ISO Class 1-8 cleanroom applications in industries like pharmaceuticals, microelectronics, and healthcare. We offer media with low outgassing binders to prevent contamination in sensitive environments.

Q3: What are your typical lead times for custom orders?

A3: Lead times for custom glass fiber filter media orders vary depending on the complexity of the specification and order volume. For standard customizations (e.g., specific width/length cuts or minor binder adjustments), lead times are typically 4-6 weeks. For highly specialized R&D projects, timelines will be established collaboratively with the client based on development milestones. We maintain a strong inventory of raw materials to expedite common requests.

Q4: What kind of warranty and after-sales support do you offer?

A4: We stand by the quality of our products with a comprehensive performance warranty, ensuring that our glass fiber filter media meets or exceeds the agreed-upon technical specifications for a period of [e.g., 12 months] from the date of delivery. Our dedicated after-sales support team provides technical assistance, troubleshooting, and advice on optimizing filter performance and extending service life. We also offer on-site consultation and training for complex applications.

Conclusion

The role of glass fiber filter media in modern industrial and environmental applications cannot be overstated. From ensuring critical air purity in semiconductor manufacturing to safeguarding public health in healthcare facilities, the demand for reliable, high-performance filtration solutions continues to grow. Our Glass Microfiber Air Filter Paper exemplifies cutting-edge technology, offering superior efficiency, extended service life, and robust chemical and thermal resistance. With a commitment to quality, adherence to international standards, and a focus on tailored solutions, we empower our B2B partners to achieve their most demanding filtration objectives while realizing significant operational efficiencies and cost savings.

References

- International Organization for Standardization (ISO). "ISO 16889: Hydraulic fluid power – Filters – Multi-pass method for evaluating filtration performance of a filter element." 2008.

- European Committee for Standardization (CEN). "EN 1822-1: High efficiency air filters (EPA, HEPA and ULPA) – Part 1: Classification, performance testing, marking." 2019.

- U.S. Environmental Protection Agency (EPA). "Indoor Air Quality Scientific Findings." Available at: www.epa.gov/indoor-air-quality-iaq/indoor-air-quality-scientific-findings

- Global Market Insights. "Air Filtration Market Size, Industry Analysis Report, Regional Outlook, Application Potential, Price Trends, Competitive Market Share & Forecast, 2020 – 2027." Available at: www.gminsights.com/industry-analysis/air-filtration-market

Post time: Aug-29-2025