Advanced Filtration: The Role of Synthetic Air Filter Media Rolls

In the intricate landscape of industrial and commercial air purification, the selection of high-performance filter media is paramount. Modern challenges, ranging from stringent indoor air quality regulations to escalating energy costs, demand innovative solutions. This comprehensive guide delves into the capabilities and advantages of synthetic air filter media rolls, specifically focusing on Synthetic Polypropylene Laminate Media Roll technology. Engineered for superior particulate capture and optimized airflow, these media rolls represent a significant advancement in meeting diverse filtration requirements across critical sectors.

The demand for efficient, durable, and cost-effective air filtration solutions continues to surge. Our exploration will cover everything from manufacturing processes and technical specifications to application scenarios, vendor comparisons, and the crucial aspects of (Expertise, Experience, Authoritativeness, Trustworthiness) that define leading suppliers in this specialized field.

Current Industry Trends in Air Filter Media

The global market for air filtration is undergoing rapid evolution, driven by several key trends:

- Increasing Emphasis on Indoor Air Quality (IAQ): Growing public awareness and regulatory pressures are pushing for higher filtration standards in commercial, industrial, and residential settings. This fuels demand for media capable of capturing finer particulate matter (PM2.5, PM10) and allergens.

- Energy Efficiency: A significant operational cost for HVAC systems is the energy consumed by fans overcoming static pressure. Filter media with lower initial pressure drop and sustained efficiency reduce energy consumption, making low-resistance synthetic air filter media rolls highly desirable.

- Sustainability and Material Innovation: There's a push towards filter media manufactured with environmentally conscious processes and materials, or those offering extended service life to reduce waste. Synthetic materials, particularly polypropylene, offer excellent durability and can often be recycled in specific streams.

- Advanced Materials and Nanotechnology: Research into new fiber structures, electrostatically charged media, and composite layers is leading to filters with enhanced capture efficiency without compromising airflow. Multi-layered laminate media, like our Synthetic Polypropylene Laminate Media Roll, exemplify this trend.

- Smart Filtration Solutions: Integration with IoT for real-time monitoring of filter condition, predictive maintenance, and optimized replacement schedules is becoming more prevalent, further emphasizing the need for reliable, long-lasting media.

These trends highlight the critical need for advanced, high-performance filtration solutions that are both effective and economically viable for businesses.

Manufacturing Process Flow of Synthetic Polypropylene Laminate Media Rolls

The production of high-quality synthetic air filter media rolls is a meticulously controlled process, leveraging advanced polymer science and textile engineering to achieve optimal filtration characteristics. Our Synthetic Polypropylene Laminate Media Roll undergoes a sophisticated manufacturing journey:

Process Steps:

- Material Preparation: High-grade polypropylene (PP) granules are selected for their excellent chemical resistance, thermal stability, and low moisture absorption. These polymers are fed into extruders.

- Melt-Blown Fiber Extrusion: Molten PP is extruded through fine dies into high-velocity air streams, creating extremely fine, randomly oriented microfibers. This melt-blown layer forms the primary filtration matrix, offering high efficiency and low pressure drop due to its large surface area and intricate fiber structure.

- Spunbond Non-Woven Production: Simultaneously, another layer is produced using the spunbond method. Here, extruded PP filaments are laid onto a conveyor belt in a continuous, random manner and then thermally bonded. This layer typically provides structural integrity and a coarser pre-filtration stage.

- Electrostatic Charging (Optional but Recommended): For enhanced efficiency, especially in capturing sub-micron particles, the melt-blown layer can be subjected to an electrostatic charging process. This imparts a static charge to the fibers, allowing them to attract and hold oppositely charged particles, significantly boosting filtration performance without increasing resistance.

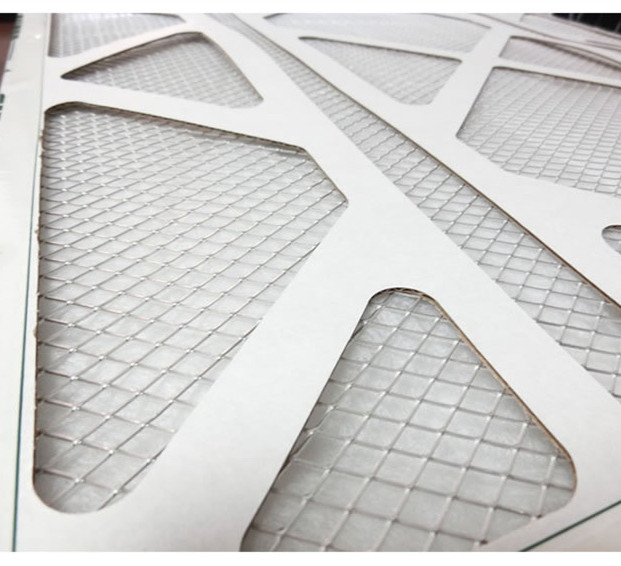

- Lamination and Bonding: The melt-blown and spunbond layers are precisely combined and thermally bonded under controlled temperature and pressure. This lamination creates a multi-layered structure that offers both high efficiency and robust mechanical strength, preventing fiber shedding.

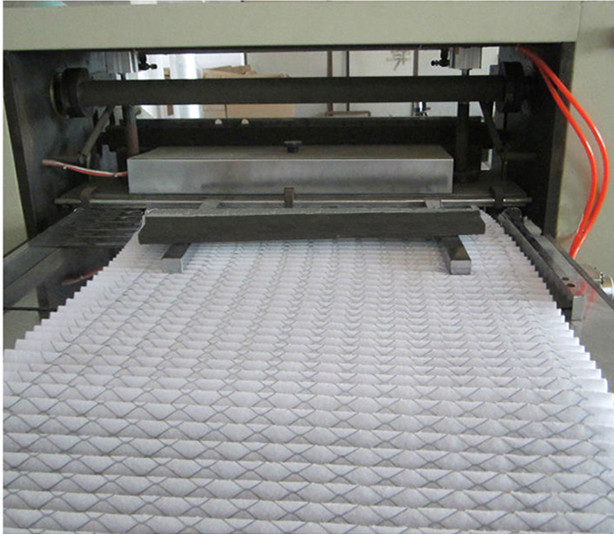

- Slitting and Winding: The wide media is then precisely slit into specified widths and wound onto cores to form continuous rolls, ensuring consistent tension and uniform density.

- Quality Control & Testing: Each batch undergoes rigorous testing to meet international standards.

Testing Standards and Compliance:

Our media rolls comply with stringent global filtration standards to ensure consistent performance and reliability:

- ISO 16890: Defines testing procedures and classification systems for air filters for general ventilation, categorizing filters based on their efficiency against different particulate matter fractions (ePM1, ePM2.5, ePM10).

- ASHRAE 52.2: Specifies methods for testing general ventilation air-cleaning devices for removal efficiency by particle size, resulting in a MERV (Minimum Efficiency Reporting Value) rating.

- UL 900: Tests for flammability of air filter units, ensuring safety in various applications. Our media typically meets UL 900 Class 1 or Class 2.

Target Industries and Advantages:

The superior characteristics of synthetic media make them ideal for a wide array of demanding industries:

- Petrochemical: Corrosion resistance to harsh chemicals, long service life in challenging environments.

- Metallurgy: High dust holding capacity for heavy particulate loads, energy saving through low pressure drop.

- Water Supply & Drainage (Air Ventilation): Moisture resistance, prevention of microbial growth in humid conditions.

- HVAC & Cleanrooms: High efficiency for critical air quality, consistent performance over time.

- Automotive (Cabin Filters): Fine particulate filtration, durability, and integration into compact designs.

Key Technical Specifications of Synthetic Polypropylene Laminate Media Rolls

Understanding the precise technical parameters is crucial for selecting the optimal synthetic air filter media rolls for specific applications. Our Synthetic Polypropylene Laminate Media Roll offers a range of configurations to meet diverse performance requirements.

Typical Product Specification Table (Example for G4 - F8 grades):

| Parameter | Unit | Typical Range (G4 - F8) |

|---|---|---|

| Material Composition | - | Synthetic Polypropylene Laminate (Melt-blown + Spunbond) |

| Filter Class (ISO 16890) | - | ISO Coarse 60% - ePM1 60% |

| Filter Class (ASHRAE 52.2) | MERV | 8 - 14 |

| Basis Weight | g/m² | 100 - 300 |

| Media Thickness | mm | 0.8 - 3.5 |

| Initial Pressure Drop (at 0.25 m/s) | Pa | 15 - 70 |

| Dust Holding Capacity | g/m² | 200 - 600 |

| Maximum Operating Temperature | °C | 80 - 100 |

| Flame Retardancy | Standard | UL 900 Class 1 or 2 |

| Moisture Resistance | - | Excellent |

| Chemical Resistance | - | Good to most acids, alkalis, and solvents |

Note: Specific parameters may vary based on grade, construction, and customer requirements. Consult our technical team for detailed datasheets.

Diverse Application Scenarios

The versatility and performance of synthetic air filter media rolls make them indispensable across a multitude of industrial and commercial applications:

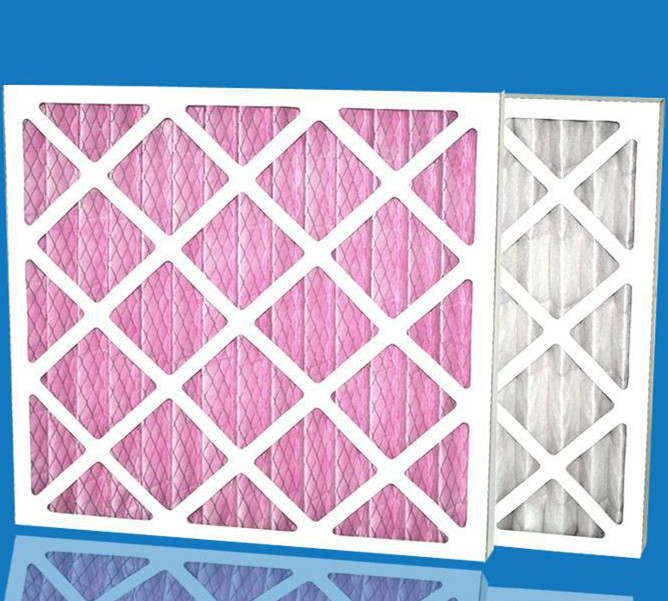

- HVAC Systems (Commercial & Industrial): From large office complexes and shopping malls to manufacturing plants, synthetic media are used in pre-filters and fine filters (e.g., G4 to F8/MERV 8-14) to protect coils, improve IAQ, and extend the life of higher-efficiency filters.

- Cleanrooms and Controlled Environments: In pharmaceutical, electronics, and semiconductor manufacturing, precise air quality control is critical. Synthetic media serve as crucial pre-filtration stages, preventing premature loading of HEPA/ULPA filters.

- Hospitals and Healthcare Facilities: Essential for maintaining sterile environments, controlling airborne pathogens, and protecting sensitive equipment. Synthetic media's resistance to moisture and microbial growth is a significant advantage.

- Data Centers: Ensuring dust-free cooling for sensitive electronic equipment, preventing hardware failures, and maintaining optimal operating temperatures.

- Food and Beverage Processing: Preventing contamination of products and processes, where hygiene and air purity are non-negotiable.

- Automotive Industry: Used in paint spray booths to remove overspray particles, and increasingly in cabin air filters for passenger vehicles to improve in-car air quality.

- Gas Turbines and Compressor Intakes: Protecting sensitive machinery from particulate damage, ensuring efficient operation and extending service intervals.

Technical Advantages and Performance Benefits

The inherent properties of polypropylene, combined with advanced manufacturing techniques, bestow significant technical advantages upon our synthetic air filter media rolls:

- High Filtration Efficiency: Multi-layered designs, often incorporating melt-blown and spunbond layers, achieve high arrestance and fine particle capture (ePM1, PM2.5), consistently meeting or exceeding specified MERV/ISO ratings. Electrostatic charging further enhances this.

- Low Initial Pressure Drop: The optimized fiber structure minimizes resistance to airflow, leading to reduced energy consumption for HVAC fans and lower operational costs. This is a critical factor for facilities aiming for LEED certification or energy reduction targets.

- High Dust Holding Capacity: The deep loading capacity of synthetic media means filters can hold more dust over time before reaching their terminal pressure drop, extending service intervals and reducing maintenance frequency and costs.

- Moisture Resistance: Polypropylene is hydrophobic, meaning it does not absorb moisture. This prevents media degradation in humid environments and inhibits the growth of bacteria, mold, and fungi, a crucial advantage in many industrial and healthcare settings.

- Chemical Resistance: Synthetic media exhibit excellent resistance to a wide range of acids, alkalis, and common industrial chemicals, making them suitable for harsh operating conditions where traditional media might fail.

- Fiber Shedding Resistance: The lamination and thermal bonding processes significantly reduce fiber shedding, preventing downstream contamination, which is vital for cleanroom and sensitive equipment protection.

- Mechanical Strength and Durability: Synthetic fibers offer superior tensile strength and abrasion resistance, ensuring the media retains its integrity even under fluctuating air velocities and during handling.

- Consistent Performance: Unlike some natural fiber alternatives, synthetic media maintain stable performance characteristics throughout their service life, providing reliable air quality control.

Vendor Comparison: Choosing Your Filtration Partner

Selecting the right supplier for air filter media rolls is as critical as choosing the product itself. A reliable vendor offers not just quality products but also technical expertise, customization capabilities, and dependable support. Below is a comparative overview:

Comparative Table of Filter Media Suppliers:

| Feature | Our Product (Synthetic Polypropylene Laminate Media Roll) | Competitor A (Standard Synthetic) | Competitor B (Glass Fiber Media) |

|---|---|---|---|

| Filtration Efficiency (MERV/ISO) | G4 to F9 (ISO Coarse 60% to ePM1 70%) | G3 to F7 (ISO Coarse 45% to ePM2.5 50%) | G4 to F8 (ISO Coarse 80% to ePM2.5 60%) |

| Material Composition | Multi-layered PP (Melt-blown + Spunbond) | Single-layer PP or PET | Glass microfibers with binder |

| Moisture Resistance | Excellent (Hydrophobic PP) | Good | Moderate (can degrade with prolonged exposure) |

| Fiber Shedding | Minimal to None (Laminated structure) | Low | Can be higher, especially when disturbed |

| Energy Efficiency (Lower Pressure Drop) | Superior | Good | Good, but often less consistent |

| Durability & Service Life | Excellent, extended life | Good | Moderate, can be brittle |

| Customization Options | Extensive (width, length, grade, special treatments) | Limited | Moderate |

This comparison highlights the superior characteristics and flexibility offered by our Synthetic Polypropylene Laminate Media Rolls, especially for applications demanding high performance and customization.

Customized Solutions for Unique Requirements

Recognizing that no two filtration challenges are identical, we specialize in providing tailored synthetic air filter media rolls. Our deep understanding of material science and filtration mechanics allows us to engineer media rolls that precisely match your operational parameters and performance targets.

- Varied Filtration Grades: From pre-filtration (ISO Coarse/MERV 8) to fine filtration (ePM1 70%/MERV 14), we can adjust fiber density, layer configuration, and electrostatic charge to achieve the desired efficiency.

- Dimensions: Media rolls can be customized in terms of width and length to integrate seamlessly into existing manufacturing lines for filter production, minimizing waste and optimizing throughput.

- Special Treatments: Options include enhanced flame retardancy (to specific UL standards), anti-microbial treatments for sensitive environments, and UV stabilization for applications exposed to direct sunlight.

- Multi-Layer Composites: Beyond standard laminate, we can design complex multi-layer structures combining different fiber sizes and material properties to address specific challenges like oil mist separation or odor absorption (with activated carbon integration).

- Pilot Roll Development: For complex projects, we offer pilot roll production for testing and validation, ensuring the customized solution performs optimally before full-scale deployment.

Our technical team collaborates closely with clients, utilizing decades of experience to transform specific requirements into effective, high-performing filter media solutions.

Application Case Studies

Real-world application demonstrates the tangible benefits of our Synthetic Polypropylene Laminate Media Rolls.

Case Study 1: HVAC System Upgrade for a Large Commercial Building

Client: A prominent commercial office tower in a densely populated urban area.

Challenge: The building's existing HVAC system utilized outdated glass fiber media, leading to frequent filter changes (every 3 months), inconsistent IAQ, and high energy consumption due to increasing static pressure.

Solution: We recommended transitioning to our Synthetic Polypropylene Laminate Media Roll (MERV 11 equivalent). Our technical team assisted with media selection and integration into their existing filter frame production line.

Results:

- Extended Service Life: Filter change intervals increased from 3 to 6-7 months, reducing maintenance labor and material costs by over 40%.

- Energy Savings: Initial pressure drop was reduced by 25% compared to the previous media, resulting in a documented 12% reduction in HVAC fan energy consumption.

- Improved IAQ: Occupant complaints related to dust and allergens significantly decreased, supported by independent air quality monitoring.

Case Study 2: Industrial Cleanroom Particulate Control

Client: A leading manufacturer of precision electronics requiring ISO Class 7 cleanroom conditions.

Challenge: Maintaining strict particulate counts in a high-volume manufacturing environment, with pre-filters needing frequent replacement due to high dust loads, impacting operational efficiency.

Solution: We provided a custom-designed, high-dust-holding-capacity Synthetic Polypropylene Laminate Media Roll (ISO ePM10 70% equivalent to MERV 10) for their pre-filter banks. The media was designed for specific roll widths to fit their automated pleating machinery.

Results:

- Reduced Filter Changes: Pre-filter life was extended by over 50%, significantly reducing downtime and labor costs associated with maintenance.

- Stable Cleanroom Conditions: The improved dust holding capacity and consistent efficiency of the synthetic media helped maintain stable particulate levels, reducing the load on expensive HEPA filters.

- Cost Savings: Overall filter consumables and maintenance costs were reduced by approximately 20% annually.

Frequently Asked Questions (FAQ)

- Q: What is the primary difference between synthetic and glass fiber filter media?

- A: Synthetic media, typically polypropylene, are hydrophobic, highly resistant to moisture and microbial growth, and generally more robust against fiber shedding. Glass fiber media can be more susceptible to moisture degradation and may shed fibers. Synthetic media also often achieve lower initial pressure drops for equivalent efficiency, leading to energy savings.

- Q: How does MERV rating correlate with ISO 16890 classification?

- A: MERV (Minimum Efficiency Reporting Value) is an ASHRAE 52.2 standard, while ISO 16890 classifies filters based on efficiency against PM10, PM2.5, and PM1 (ePMx). While there's no direct one-to-one conversion, a higher MERV generally corresponds to higher ePMx efficiency. For example, MERV 11 is roughly equivalent to ISO ePM2.5 50-60%.

- Q: Can these media rolls be used for manufacturing filters for medical applications?

- A: Yes, our synthetic polypropylene laminate media can be engineered to meet the stringent filtration requirements for medical-grade air filters, often used in hospitals, clinics, and pharmaceutical cleanrooms. Specific certifications (e.g., biocompatibility) would need to be discussed for direct patient contact applications.

- Q: What is the typical service life of filters made from your media?

- A: The service life depends heavily on the operating environment (dust concentration), airflow volume, and the filter's design. However, filters manufactured with our Synthetic Polypropylene Laminate Media Rolls typically offer an extended service life due to their high dust holding capacity and durability, often lasting 25-50% longer than traditional alternatives in similar applications.

Lead Time, Warranty, and Customer Support

We are committed to providing comprehensive support and transparency to our B2B partners.

Lead Time and Fulfillment:

Standard lead times for our synthetic air filter media rolls typically range from 3 to 6 weeks, depending on the order volume and customization requirements. Expedited options are available for urgent needs. We maintain robust logistics networks to ensure timely and secure delivery worldwide. Minimum Order Quantities (MOQs) apply and can be discussed with our sales team.

Warranty Commitments:

We stand behind the quality of our products. Our Synthetic Polypropylene Laminate Media Rolls come with a standard 12-month warranty against manufacturing defects from the date of purchase. This warranty covers material integrity and performance specifications as outlined in our technical datasheets. Full warranty terms and conditions are available upon request.

Comprehensive Customer Support:

- Technical Assistance: Our team of experienced filtration engineers provides expert guidance on media selection, application optimization, and technical queries.

- Design Consultation: We offer collaborative design services to develop customized media solutions perfectly integrated with your filter manufacturing processes and end-product requirements.

- After-Sales Service: Dedicated support ensures smooth order processing, logistics coordination, and prompt resolution of any post-purchase inquiries.

Our commitment to partnership ensures you receive not just a product, but a complete filtration solution backed by unparalleled expertise and service.

Conclusion

The landscape of air filtration is continuously evolving, demanding increasingly efficient, durable, and specialized media. Synthetic Polypropylene Laminate Media Rolls, with their advanced multi-layered construction and inherent material advantages, stand out as a premier solution for a broad spectrum of B2B applications. By delivering superior filtration efficiency, extended service life, and significant energy savings, these media rolls empower businesses to meet stringent air quality standards while optimizing operational costs. Partnering with a supplier that embodies expertise, experience, authoritativeness, and trustworthiness ensures access to not only cutting-edge products but also the technical support and customized solutions essential for success in today's demanding industrial environments.

References

- ISO 16890-1:2016. "Air filters for general ventilation – Part 1: Technical specifications, requirements and classification system based upon particulate matter efficiency (ePM)." International Organization for Standardization.

- ASHRAE Standard 52.2-2017. "Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size." American Society of Heating, Refrigerating and Air-Conditioning Engineers.

- Liu, W., & Xu, Z. (2018). "Advances in electrospun nanofiber air filters: A review." Journal of Membrane Science, 549, 269-282.

- Spitz, F. (2018). "Air Filtration for HVAC Systems: A Guide for Specifying Filters, IAQ, and Energy Efficiency." CRC Press.

- UL 900. "Standard for Air Filter Units." Underwriters Laboratories Inc.

Post time: Aug-28-2025