Understanding Flame Retardant Paper in Industrial Applications

In diverse industrial environments, the imperative for safety and operational resilience is paramount. This drives the demand for specialized materials that mitigate risk, particularly concerning fire hazards. Among these, flame retardant paper stands out as a critical component, especially in filtration media. As a material engineered to resist ignition and slow the spread of fire, it offers enhanced protection in applications ranging from HVAC systems to industrial dust collection, safeguarding personnel and sensitive equipment. The unique composition and manufacturing processes of these papers enable them to meet stringent safety standards without compromising functional performance, such as filtration efficiency.

The market for specialized filter media, including fire retardant paper, is experiencing steady growth driven by stricter regulatory frameworks, increasing industrial automation, and the rising awareness of workplace safety. Industries like petrochemicals, pharmaceuticals, automotive, and power generation are continuously seeking advanced materials that offer not only superior operational performance but also robust safety features. The global market for industrial filtration is projected to reach USD 45 billion by 2027, with flame retardant variants comprising a significant and growing segment due to their indispensable safety benefits. This expansion is further fueled by innovations in material science, leading to more effective and environmentally compliant flame retardant chemistries.

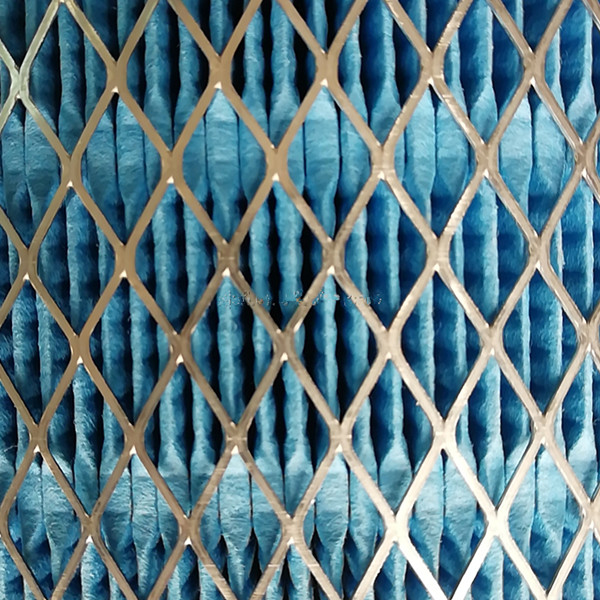

At Anya Filter Media, our High Filtration Efficiency Flame-Retardant Filter Paper represents the pinnacle of this technological advancement. Engineered for demanding B2B applications, this product combines exceptional filtration capabilities with crucial fire safety properties, making it an ideal choice where both performance and protection are non-negotiable.

Manufacturing Process of Flame Retardant Paper

The production of flame retardant paper is a sophisticated process that integrates specialized chemical treatments into conventional paper manufacturing. This ensures that the final product not only performs its primary function, such as filtration, but also actively resists combustion. The core methodology involves either incorporating flame retardant chemicals directly into the pulp slurry or applying them as a coating or impregnation post-formation.

Detailed Process Flow:

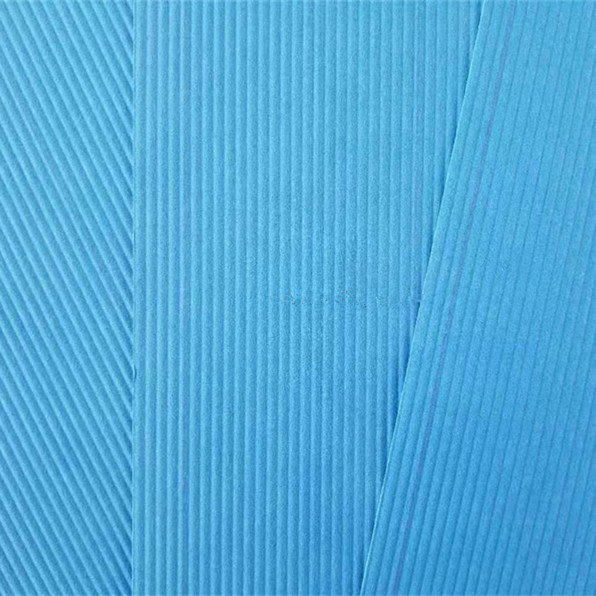

- 1. Pulp Preparation: High-quality cellulose fibers, often a blend of wood pulp and synthetic fibers (e.g., polyester, fiberglass for enhanced strength and thermal stability), are sourced. These fibers are then pulped and refined to achieve the desired fiber length distribution and surface characteristics, crucial for subsequent processing and final paper properties.

- 2. Flame Retardant Integration (Wet-End Addition): This is a critical step where specific flame retardant chemicals are introduced directly into the fiber slurry. Common flame retardants include phosphorus-based compounds (e.g., ammonium polyphosphate), nitrogen-based compounds (e.g., guanidine salts), and mineral hydroxides (e.g., aluminum hydroxide, magnesium hydroxide). These chemicals are uniformly dispersed to ensure consistent fire resistance throughout the paper matrix.

- 3. Sheet Formation: The treated pulp slurry is then fed onto a paper machine, typically a Fourdrinier, where it forms a continuous wet web. Water is drained, leaving a nascent paper sheet. For filtration applications, careful control of fiber dispersion and pore structure is vital to achieve desired permeability and efficiency.

- 4. Pressing and Drying: The wet web undergoes mechanical pressing to remove excess water, increasing its dry content and density. Following this, the paper is passed through heated dryer sections to evaporate residual moisture. Precise temperature and tension control during drying prevent warping and maintain structural integrity.

- 5. Post-Treatment (Coating/Impregnation): For enhanced fire resistance or specific surface properties, the dried paper may undergo additional treatments. This involves impregnating the paper with a flame retardant solution or applying a surface coating. This method often results in superior performance by creating a protective char layer upon exposure to flame, limiting oxygen supply and heat transfer.

- 6. Calendering: The paper is then calendered, a process where it passes through a series of rollers under pressure. This improves smoothness, density, and thickness uniformity, essential for consistent filtration performance and durability.

- 7. Slitting and Winding: Finally, the finished fire proof paper is slit into required widths and wound onto rolls, ready for conversion into filter cartridges or other end products.

- 8. Quality Control and Testing: Throughout the process, and especially on the final product, rigorous testing is conducted. This includes flame resistance testing (e.g., ASTM E84, NFPA 701, UL 94), filtration efficiency (e.g., EN 779, ISO 16890), air permeability, tensile strength, and basis weight. Our products are consistently tested to meet or exceed industry benchmarks like ISO and ANSI standards.

Our manufacturing process emphasizes precision and adherence to international testing standards, guaranteeing a product with extended service life and superior performance in target industries such as petrochemical, metallurgy, power generation, and water supply & drainage. The meticulous control over each stage results in a material offering significant advantages, including enhanced safety, improved energy saving through stable filtration, and inherent corrosion resistance due to material inertness.

Technical Specifications and Performance Metrics

The efficacy of flame retardant paper is quantified through a suite of technical specifications and performance metrics. These parameters are crucial for engineers and procurement specialists in selecting the appropriate media for their applications. Our High Filtration Efficiency Flame-Retardant Filter Paper is designed to excel across these critical benchmarks.

Product Specification Table: High Filtration Efficiency Flame-Retardant Filter Paper

| Parameter | Value/Range | Test Standard |

|---|---|---|

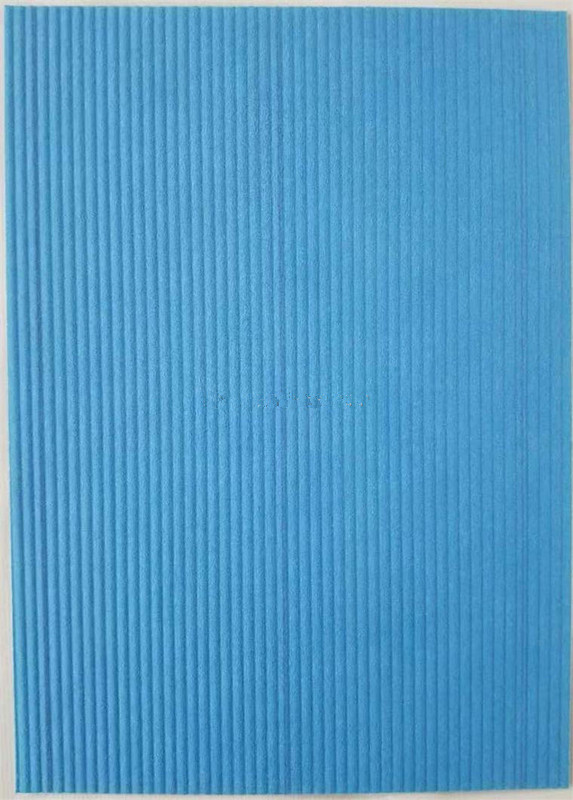

| Basis Weight | 80-250 gsm | ISO 536:2019 |

| Thickness | 0.3 - 0.9 mm | ISO 534:2011 |

| Air Permeability | 100-350 L/m²/s @ 100Pa | ISO 9237:1995 |

| Filtration Efficiency | ≥ 99.9% @ 0.3 µm (H13) | EN 1822-1:2019 |

| Initial Pressure Drop | ≤ 100 Pa @ nominal flow | EN 1822-1:2019 |

| Tensile Strength (MD) | ≥ 35 N/15mm | ISO 1924-2:2008 |

| Flame Resistance | Class A (UL 94 V-0 equivalent) | ASTM E84, NFPA 701, UL 94 |

| Max. Operating Temp. | 150°C (302°F) | Internal Test Method |

| Chemical Resistance | Excellent to most acids/alkalis | Internal Test Method |

These specifications highlight the dual functionality of our filter media: providing high-level particle retention while adhering to stringent fire safety standards. The combination of excellent filtration efficiency, robust mechanical strength, and certified flame resistance makes this an indispensable material for critical industrial applications.

Application Scenarios and Technical Advantages

The demand for fire retardant paper extends across a myriad of industrial sectors where safety, operational continuity, and compliance are paramount. Its unique blend of properties makes it indispensable in environments prone to dust explosions, high temperatures, or where sparks are a common byproduct of operations.

Key Application Industries:

- Petrochemical and Chemical Processing: Critical for air intake filtration and dust collection in explosive atmospheres, preventing ignition from static discharge or hot particles.

- Metallurgy and Metalworking: Used in fume extraction and dust control systems where grinding sparks or hot metal particles are present.

- Automotive Manufacturing: Essential in paint booths and welding areas to filter airborne particulates while minimizing fire risk.

- Power Generation: Ensures clean air supply to turbines and protects sensitive electronic equipment from particulate contamination and fire hazards.

- Electronics and Data Centers: Provides clean air for sensitive equipment, where fire suppression is critical, and a standard filter could become a fuel source.

- HVAC Systems in Public Buildings: Enhances safety in airports, hospitals, and commercial complexes, especially in ventilation systems.

Technical Advantages:

- Enhanced Safety: The primary advantage, significantly reducing the risk of fire propagation and minimizing potential damage and downtime. Complies with strict fire safety standards (e.g., NFPA, UL, ASTM).

- Operational Continuity: By preventing fires, these papers contribute to uninterrupted operations, protecting critical assets and production schedules.

- High Filtration Efficiency: Despite the flame-retardant treatment, our filter paper maintains a high filtration efficiency, capturing sub-micron particles effectively, which is crucial for air quality and equipment protection.

- Durability and Service Life: Engineered for robustness, our filter media offers excellent mechanical strength and thermal stability, contributing to a longer service life, even in challenging environments.

- Corrosion Resistance: The materials and flame retardant agents used are selected for their chemical inertness, providing superior resistance to corrosive substances often present in industrial air streams.

- Energy Saving: Stable and optimized air permeability characteristics ensure lower pressure drop across the filter, leading to reduced energy consumption for fans and blowers over the filter's lifespan.

Vendor Comparison and Customized Solutions

Choosing the right supplier for flame retardant paper is critical for achieving optimal performance and ensuring long-term reliability. While many vendors offer fire-resistant media, key differentiators lie in material quality, manufacturing consistency, certification adherence, and the ability to provide tailored solutions.

Competitive Landscape:

| Feature/Vendor | Anya Filter Media | Competitor A | Competitor B |

|---|---|---|---|

| Flame Retardancy Standard | ASTM E84 Class A, NFPA 701, UL 94 V-0 | NFPA 701 | ASTM E84 Class C |

| Filtration Efficiency (≥ 0.3 µm) | ≥ 99.9% (H13) | ≥ 99.0% (F9) | ≥ 95.0% (F8) |

| Fiber Material Blends | Proprietary Cellulose/Synthetic Blend | Standard Cellulose | Cellulose/Glass Fiber |

| Chemical Resistance | Excellent | Good | Moderate |

| Customization Capabilities | Extensive (GSM, thickness, FR level, porosity) | Limited (GSM, basic FR level) | Moderate (thickness, basic FR level) |

| Certifications/Compliance | ISO 9001, CE, RoHS, FDA (where applicable) | ISO 9001 | CE |

Anya Filter Media distinguishes itself through superior flame retardancy ratings, higher filtration efficiency, and a robust material composition, all backed by comprehensive certifications. Our commitment to quality and safety is reflected in every product, offering unparalleled peace of mind and operational excellence.

Customized Solutions:

Recognizing that every industrial application has unique demands, Anya Filter Media specializes in providing tailored fire proof paper solutions. Our engineering team works closely with clients to develop filter media that precisely meets their specific requirements, including:

- Adjustable Basis Weight and Thickness: Optimizing paper density for specific filtration needs and mechanical strength.

- Variable Flame Retardancy Levels: Tuning the degree of fire resistance to comply with particular industry regulations or operational risks.

- Enhanced Chemical Resistance: Modifying formulations for superior performance in highly corrosive environments.

- Specific Pore Sizes and Permeabilities: Customizing the fiber matrix to achieve desired filtration efficiency and pressure drop characteristics.

- Specialized Coatings: Applying hydrophobic, oleophobic, or anti-microbial coatings for enhanced functionality.

Our agile manufacturing capabilities and deep material science expertise allow us to deliver bespoke solutions that provide both superior protection and optimal performance, ensuring a perfect fit for even the most challenging industrial filter designs.

Application Case Studies

Real-world applications demonstrate the tangible benefits and proven reliability of our flame retardant paper solutions. Anya Filter Media has successfully partnered with numerous clients to enhance safety and operational efficiency across various demanding sectors.

Case Study 1: Petrochemical Refinery Dust Collection

- Challenge: A major petrochemical refinery required dust collector filters capable of handling highly combustible hydrocarbon dusts. Previous standard filter media posed a significant fire hazard, leading to frequent safety audits and potential production halts.

- Solution: Anya Filter Media supplied customized High Filtration Efficiency Flame-Retardant Filter Paper, certified to ASTM E84 Class A. The paper was integrated into new pleated filter cartridges designed for high air volumes.

- Results: After 18 months of operation, the refinery reported zero fire incidents related to the dust collection system. The filtration efficiency remained consistently high, extending the service life of filters by 30% compared to previous solutions. The enhanced safety allowed for improved operational uptime and reduced insurance premiums. Customer feedback highlighted "unwavering reliability" and "significant improvement in worker safety."

Case Study 2: Automotive Paint Shop Air Intake

- Challenge: An automotive manufacturer's paint shop faced the challenge of filtering paint overspray and airborne particulates while mitigating the risk of fire from electrical sparks and heat sources within the ventilation system. Standard filters were a potential fuel source.

- Solution: We provided a bespoke fire proof paper with a fine pore structure for superior paint particulate capture and NFPA 701 certification for flame resistance. The paper was treated with a hydrophobic coating to resist moisture accumulation.

- Results: The new filter media not only maintained optimal air quality for flawless paint finishes but also dramatically lowered fire risk. The client observed a 25% reduction in filter change-out frequency due to improved loading capacity and moisture resistance, leading to energy savings by reducing fan load and maintenance costs. The paint shop manager lauded the "exceptional safety features combined with top-tier air cleanliness."

Trust and Reliability: FAQ, Lead Times, Warranty, and Support

Building trust with B2B partners is foundational to our operations. Anya Filter Media is committed to transparency, reliability, and robust support for our clients, ensuring that every interaction and product instills confidence.

Frequently Asked Questions (FAQ):

Q: What makes your flame retardant paper superior to competitors'?

A: Our paper integrates advanced proprietary flame retardant chemistries and fiber blends, achieving higher fire resistance ratings (ASTM E84 Class A, UL 94 V-0) while maintaining industry-leading filtration efficiencies (H13). We also offer extensive customization options and adhere to stringent ISO 9001 quality controls.

Q: Is your fire retardant paper environmentally friendly?

A: We prioritize eco-friendly formulations where possible, complying with RoHS directives and minimizing the use of halogenated compounds. Our processes are designed for sustainability, and we continuously research new, greener flame retardant technologies.

Q: Can you provide certification documents for your products?

A: Absolutely. All our products come with comprehensive test reports and certification documents, including ASTM, NFPA, UL, ISO, and CE, upon request, ensuring full compliance and traceability for your quality assurance needs.

Q: How do I determine the right filter paper for my application?

A: Our experienced technical sales team and engineers are available for consultation. We perform detailed application analyses, considering factors like particulate size, air velocity, temperature, humidity, chemical exposure, and specific fire safety regulations to recommend or customize the optimal solution.

Lead Time and Fulfillment:

We understand the importance of timely delivery for industrial operations. Our standard lead time for stock fire proof paper orders typically ranges from 2-4 weeks. For custom solutions, lead times are quoted on a project-specific basis, usually 6-8 weeks, depending on complexity and material availability. We maintain robust inventory management and flexible production scheduling to meet urgent demands and large-volume orders efficiently.

Warranty Commitments:

Anya Filter Media stands behind the quality and performance of its products. Our High Filtration Efficiency Flame-Retardant Filter Paper comes with a standard 12-month warranty against manufacturing defects and material failures under normal operating conditions. Extended warranty options and performance guarantees can be discussed for specific long-term partnerships.

Customer Support:

Our commitment to our clients extends beyond delivery. Anya Filter Media provides comprehensive after-sales support, including:

- Technical Assistance: Expert guidance on installation, maintenance, and troubleshooting.

- Performance Monitoring: Consultation services to optimize filter media performance and extend service life.

- Responsive Communication: Dedicated account managers and a responsive support team available via phone and email to address any queries or concerns promptly.

We are dedicated to forging lasting partnerships built on a foundation of quality products and exceptional service, ensuring your operations remain safe and efficient.

Citations:

1. ASTM International. (2022). ASTM E84 - Standard Test Method for Surface Burning Characteristics of Building Materials. 2. National Fire Protection Association. (2019). NFPA 701 - Standard Methods of Fire Tests for Flame Propagation of Textiles and Films. 3. Underwriters Laboratories. (2020). UL 94 - Tests for Flammability of Plastic Materials for Parts in Devices and Appliances. 4. International Organization for Standardization. (2019). ISO 9001 - Quality management systems — Requirements. 5. International Organization for Standardization. (2019). EN 1822-1:2019 - High efficiency air filters (EPA, HEPA and ULPA) - Part 1: Classification, performance testing, marking. 6. Grand View Research. (2023). Industrial Filtration Market Size, Share & Trends Analysis Report.

Post time: Sep-11-2025