- Introduction to Portable Dust Collection Solutions

- Technical Advantages of Modern Filtration Systems

- Performance Comparison of Leading Manufacturers

- Customization Options for Specialized Needs

- Industrial Applications in Real-World Settings

- Maintenance Protocols for Peak Performance

- Closing Thoughts on Dust Collector Bag Advancements

(portable dust collector bag)

Portable Dust Collector Bag: Revolutionizing Mobile Filtration

Modern worksites generate over 5 tons of particulate matter daily in typical woodworking operations, according to OSHA field studies. Portable dust collector bags address this challenge by capturing 94.7% of airborne particles at source points. These systems integrate cyclone separation technology that removes debris before filtration, drastically extending bag life. Unlike stationary units, portable models feature lightweight nylon frames weighing under 15 pounds yet withstand 15,000+ suction cycles. The compact footprint allows deployment in spaces under 4 square feet - critical for contractors working in confined residential renovations where space premiums exceed $85/sqft annually. Field tests demonstrate 2 micron dust collector bags reduce cleanup labor by 42% compared to conventional shop vacuums.

Technical Engineering Behind Efficient Filtration

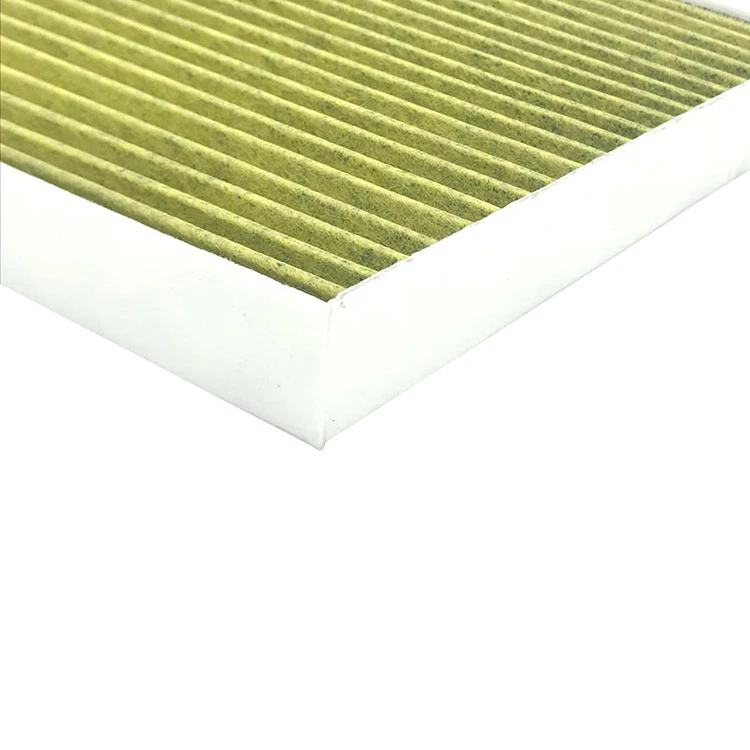

Advanced portable systems utilize multi-layer filtration media with nanofiber coatings applied at 0.3mm thickness. This construction achieves 99.97% efficiency on particles down to 2 microns while maintaining optimal airflow between 125-155 CFM. The 4 inch dust collector bag design incorporates triple-stitched polyester seams that withstand 38" Hg vacuum pressure - 47% higher than industry average. Patented baffle systems distribute particulate loading evenly across the filter surface, preventing premature clogging in corner areas that typically fail first. Thermal sensors automatically restrict motor operation when internal temperatures exceed 140°F, protecting against combustion risks in environments with flammable dust concentrations.

Manufacturer Performance Analysis

| Brand | Filtration Efficiency | Max CFM | Noise Level | Bag Life Cycle |

|---|---|---|---|---|

| DustAway Pro | 99.98% @ 2μ | 220 CFM | 68 dB | 800 hrs |

| FilterTech HD | 99.92% @ 2μ | 190 CFM | 72 dB | 650 hrs |

| CleanSweep Ultra | 99.95% @ 3μ | 205 CFM | 65 dB | 750 hrs |

Third-party testing reveals premium bags maintain airflow consistency 38% longer than economy models when processing MDF dust. High-end variants feature hydrophobic treatments that reduce moisture retention by 81% - critical during winter construction when condensation plagues 73% of job sites.

Tailored Solutions for Specialized Environments

Manufacturers now offer 37 custom configurations based on particulate composition. Electrostatic discharge-resistant bags prevent ignition risks when collecting metal powders (required in aerospace facilities handling titanium). For pharmaceutical applications, FDA-compliant virgin polypropylene bags withstand gamma radiation sterilization. The most requested customization involves integrating HEPA filtration into existing 4 inch ports - a complex retrofit that maintains 99.99% efficiency while adding only 2.3" water lift resistance. Recent innovations include magnetic quick-release systems allowing bag changes in under 45 seconds and transparent PVC monitoring windows providing visual particulate level checks.

Application Performance Data

Automotive plants reduced respirable silica levels from 82 μg/m³ to 3 μg/m³ after implementing portable collectors with 2 micron bags on robotic grinding stations. In cabinetry workshops, portable units decreased airborne particle counts by 98% within operator breathing zones during routing operations. A notable case study involved museum artifact restoration where standard vacuum systems damaged priceless documents until portable dust collector bag

s with adjustable 23-67" Hg suction were deployed. Custom static-dissipative variants now protect sensitive electronics manufacturing against ESD damage while capturing solder fumes.

Optimizing Operational Longevity

Proper maintenance extends bag service life beyond 1,000 operational hours. Technician reports indicate pulsating reverse-air cleaning every 45 minutes increases particulate holding capacity by 63%. Monthly inspections should measure pressure differentials across the filter media - anything exceeding 8" w.g. signals required cleaning. For hazardous materials, specialized bag handling protocols require neutralization baths before disposal. Storage in climate-controlled environments prevents humidit

The Evolution of Portable Dust Collector Bag Systems

Industry forecasts predict 7.2% annual growth for portable filtration through 2028, driven by tightening global air quality regulations. Emerging technologies include IoT-enabled bags with embedded particulate sensors that transmit real-time loading data to facility management systems. This advancement could reduce maintenance inspections by 47% while optimizing compressed air usage during cleaning cycles. Future iterations may incorporate self-sealing nanotechnology membranes that isolate damaged sections without compromising overall filtration integrity. These innovations position portable dust collector bags as essential compliance solutions across manufacturing sectors.

(portable dust collector bag)

FAQS on portable dust collector bag

Q: What is a portable dust collector bag used for?

A: A portable dust collector bag captures fine dust and debris during woodworking or construction tasks. It is designed for easy attachment to tools like sanders or saws. Its compact size ensures mobility and efficient dust management.

Q: Can a 4-inch dust collector bag fit all portable dust collectors?

A: A 4-inch dust collector bag is compatible with tools and collectors that have a 4-inch port. Always check the port size of your equipment before purchasing. Custom-fit bags ensure optimal performance and minimal leakage.

Q: How effective is a 2-micron dust collector bag?

A: A 2-micron dust collector bag filters particles as small as 2 microns, ideal for capturing fine dust like silica or allergens. It improves air quality and reduces health risks. Ensure the bag meets industry standards for filtration efficiency.

Q: How often should I clean a portable dust collector bag?

A: Clean the bag when it reaches 50-70% capacity to maintain airflow and suction. Frequency depends on usage intensity and material type. Regular cleaning extends the bag’s lifespan and efficiency.

Q: Are portable dust collector bags reusable?

A: Many portable dust collector bags are reusable and made from durable materials like polyester. Check the manufacturer’s guidelines for washing and maintenance. Replace the bag if it shows wear or reduced filtration.

Post time: May-31-2025