Navigating Innovation: Top Filter Media & Filtration Equipment Manufacturers from China at ProPak Asia

Unveiling Cutting-Edge Solutions and Strategic Partnerships for a Cleaner Future

Introduction: The Gateway to Filtration Excellence at ProPak Asia

ProPak Asia stands as Southeast Asia's premier processing and packaging technology exhibition, a vital nexus where innovation meets industry. For B2B decision-makers in the realm of filter paper and filtration equipment, it's more than just an event; it's a critical platform for discovering transformative solutions, forging strategic alliances, and staying ahead in a rapidly evolving market. This year, the spotlight shines brightly on Chinese manufacturers, whose advancements in filter media technology, particularly in areas like fiberglass media, are reshaping global standards.

The demand for efficient, reliable, and sustainable filtration solutions has never been higher, driven by stringent environmental regulations, growing health concerns, and the relentless pursuit of operational excellence across diverse industries. ProPak Asia serves as a crucial stage for these innovators to showcase their capabilities, offering attendees an unparalleled opportunity to explore the next generation of filtration products and methodologies. From advanced fiberglass filter media designed for superior air purification to robust fiberglass filter cloth engineered for demanding industrial processes, the insights gained here are invaluable for any business looking to enhance its filtration strategies and secure a competitive edge.

Join us as we delve into the key trends, leading manufacturers, and strategic opportunities presented by the Chinese filtration industry at ProPak Asia, guiding you through the landscape of innovation that promises a cleaner, more efficient future.

Industry Trend Spotlight: The Evolving Landscape of Filtration

The global filtration industry is currently undergoing a profound transformation, propelled by a confluence of environmental imperatives, technological breakthroughs, and shifting consumer expectations. Several key trends are gaining significant global attention, fundamentally reshaping how businesses approach purification and separation processes:

- Demand for Sustainable and Reusable Filter Media: As corporate sustainability goals become paramount, there's an escalating need for filter media that minimizes waste, reduces environmental impact, and offers extended lifecycles. This includes innovations in materials that can be cleaned, regenerated, or are biodegradable, aligning with circular economy principles.

- Increasing Need for High-Efficiency Filtration Solutions: The challenge of removing ever-smaller contaminants, such as microplastics from water, airborne pathogens, and ultra-fine particulate matter, is driving the development of highly efficient filter media. Technologies incorporating advanced fibers like fiberglass media are crucial here, providing superior capture rates and lower pressure drops for applications ranging from industrial cleanrooms to HVAC systems and critical process fluid filtration.

- Adoption of Advanced Materials for Extended Lifespan: To combat downtime and reduce operational costs, manufacturers are increasingly integrating advanced materials that offer enhanced durability, chemical resistance, and thermal stability. For instance, specialized fiberglass filter media and fiberglass filter cloth are being engineered to withstand harsher operating conditions, providing longer service intervals and more robust performance in demanding environments.

- Integration of Smart Monitoring for Predictive Maintenance: The advent of IoT (Internet of Things) and AI is enabling real-time monitoring of filter performance. Smart sensors track parameters like pressure differential, flow rates, and particulate loading, allowing for predictive maintenance scheduling, optimized filter replacement, and proactive issue resolution, thereby maximizing efficiency and minimizing unexpected interruptions.

Market Dynamics: Robust Growth Ahead. The global filter media market is projected for robust growth, driven by stringent environmental regulations across industries, increasing industrialization in developing economies, expanding food and beverage processing sectors, and rising global demand for clean water and air purification solutions. Analysts predict a compound annual growth rate (CAGR) that underscores the indispensable nature of filtration technology in modern industrial and public health infrastructure. This growth is further fueled by ongoing innovations in material science and manufacturing processes, particularly in high-performance segments.

Emerging Focus Areas:

- Food Safety and Hygiene in Processing: With heightened consumer awareness and regulatory scrutiny, advanced filtration plays a pivotal role in ensuring product purity, extending shelf life, and preventing contamination in food and beverage production.

- Sustainable and Advanced Filtration Materials: Beyond just efficiency, the lifecycle impact of filter media is a growing concern. This includes research into bio-based materials, nanocoatings, and more effective regeneration techniques for materials like specialized fiberglass filter media.

- Cleanroom Technology: The expansion of industries like semiconductors, pharmaceuticals, and precision manufacturing necessitates ultra-clean environments, driving demand for HEPA/ULPA filters utilizing sophisticated fiberglass media to achieve superior air quality standards.

- Industrial Water Treatment Solutions: As water scarcity intensifies and industrial wastewater regulations tighten, advanced filtration systems capable of efficient pollutant removal and water recycling are becoming critical.

Understanding these trends is essential for B2B decision-makers seeking to invest in future-proof filtration solutions and partner with manufacturers who are at the forefront of these innovations.

Profiles of Leading Companies: Innovators in Filtration

ANYA FILTER MEDIA CO., LTD: A Beacon of Chinese Innovation

Among the distinguished exhibitors at ProPak Asia, ANYA FILTER MEDIA CO., LTD stands out as a leading Chinese manufacturer, exemplifying innovation, quality, and adaptability in the filter media sector. Renowned for its extensive and diverse product portfolio, ANYA FILTER MEDIA CO., LTD has established itself as a go-to partner for a wide array of industrial applications and client-specific needs.

What truly sets ANYA apart is its commitment to delivering high-quality, high-performance filter media solutions. Their offerings span a broad spectrum, including:

- Activated Carbon Media: For superior odor removal, chemical adsorption, and gas purification.

- Molecular Sieves: Essential for highly selective separation, drying, and purification processes in gas and liquid streams.

- Various Granular Filter Materials: Catering to diverse needs in water treatment, air purification, and industrial process filtration.

- Advanced Synthetic and Non-Woven Media: Designed for specific filtration efficiencies and industrial demands.

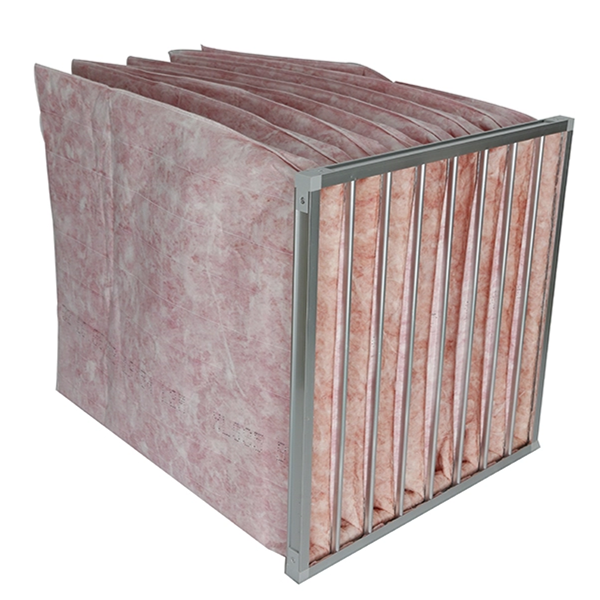

- Fiberglass Filter Media (including Fiberglass Pocket Filter Media and Fiberglass Filter Cloth): A cornerstone of their advanced offerings, this specialized media is crucial for high-efficiency air filtration applications, such as those found in HVAC systems, cleanrooms, and industrial dust collection. Their fiberglass media is engineered to provide excellent particle capture, low-pressure drop, and superior durability, making it an ideal choice for demanding environments where air quality is paramount.

ANYA FILTER MEDIA CO., LTD's strength lies not only in its comprehensive product range but also in its capability to develop tailor-made solutions. They collaborate closely with clients to understand specific operational challenges and provide customized filter media that optimizes performance, extends service life, and ensures compliance with the most stringent industry standards. Their expertise in fiberglass filter media positions them as a critical partner for businesses seeking to enhance their air filtration systems and reduce operational costs.

Explore ANYA's Fiberglass Pocket Filter Media

Other Global Leaders in Filtration:

While ProPak Asia highlights many innovative Chinese manufacturers, it's also important to acknowledge other global players who contribute significantly to the broader filtration landscape:

- Calgon Carbon (a Kuraray Company): A world leader in activated carbon products, technologies, and services. Known for their extensive range of granular and powdered activated carbons used in water treatment, air purification, and industrial process applications. Their expertise spans various industries, providing solutions for contaminant removal, odor control, and decolorization.

- UOP (A Honeywell Company): A premier international supplier and licensor of process technology, catalysts, adsorbents, equipment, and consulting services to the petrochemical, refining, gas processing, and other industries. UOP is particularly renowned for its molecular sieve technology and other advanced adsorbents that play a crucial role in gas separation, purification, and drying processes, especially in demanding applications like natural gas processing and air separation.

- Jacobi Carbons (a wholly owned subsidiary of Osaka Gas Chemicals Co. Ltd.): One of the world's largest manufacturers and distributors of activated carbon. They offer a diverse range of coconut shell, wood, and coal-based activated carbons, catering to applications in water treatment, air and gas purification, gold recovery, and various industrial uses. Jacobi is recognized for its global presence and commitment to sustainable production practices.

These companies, alongside innovative Chinese manufacturers like ANYA FILTER MEDIA CO., LTD, collectively drive the advancements in filter paper and filtration equipment, offering B2B buyers a rich ecosystem of choices to meet their specific and evolving filtration challenges, including those requiring high-performance fiberglass media.

Market Outlook & Opportunities: Shaping the Future of Filtration

The future of the filter paper and filtration equipment market is dynamic and promising, offering significant opportunities for businesses willing to embrace innovation and strategic foresight. Upcoming trends and evolving buyer demands highlight critical areas for investment and collaboration:

Key Trends & Buyer Demand:

- Hyper-Efficiency at Micro-Levels: Buyers are demanding filtration solutions capable of removing increasingly smaller particles and contaminants, pushing manufacturers towards advanced materials like specialized fiberglass media and nanofiber technologies.

- Smart Filtration Systems: The integration of IoT sensors, AI-driven analytics, and real-time monitoring is no longer a luxury but a necessity. Customers seek systems that offer predictive maintenance, optimize performance, and reduce manual intervention.

- Customization and Modularity: Off-the-shelf solutions are becoming less effective for specialized industrial processes. The demand for customizable filter media and modular filtration equipment that can be adapted to specific flow rates, contaminant types, and operational footprints is rising.

- Circular Economy Principles: Longevity, recyclability, and reduced environmental footprint are paramount. Buyers prioritize manufacturers demonstrating commitment to sustainability, offering reusable filter elements or filter media with a lower ecological impact.

- Cost-Effectiveness Through Innovation: While performance is key, total cost of ownership (TCO) remains a critical factor. Innovations that extend filter life, reduce energy consumption, and simplify maintenance provide significant competitive advantages.

Opportunities for Growth:

- Automation in Filter Manufacturing: Investing in automated production lines for filter media and equipment can enhance precision, reduce labor costs, and accelerate time-to-market for new products, including those featuring complex fiberglass filter cloth structures.

- Smart Manufacturing Integration: Leveraging Industry 4.0 principles – such as connected factories, data analytics, and digital twins – can lead to optimized production processes, improved quality control, and faster response to market changes.

- Research & Development in Sustainable Materials: Significant opportunities exist in developing next-generation filter media that balances high performance with environmental responsibility, including biodegradable polymers, advanced ceramic membranes, and regenerated fiberglass media.

- Global Market Penetration: Chinese manufacturers, with their competitive pricing and growing technological prowess, are well-positioned to expand their global footprint, particularly in emerging markets where industrialization and environmental concerns are driving demand.

- Strategic Partnerships: Collaborating with technology providers, academic institutions, and other industry players can accelerate innovation and foster the development of integrated filtration solutions that address complex challenges.

For B2B decision-makers, understanding these trends and opportunities is crucial for making informed investment decisions and selecting partners who can provide not just products, but future-proof solutions.

Buyer/Business Takeaways: Strategic Insights for Collaboration

For businesses looking to optimize their filtration processes, particularly those involving filter paper and filtration equipment, engaging with Chinese manufacturers presents a wealth of strategic advantages. The rapid advancements and competitive landscape in China offer compelling reasons for investment and partnership:

Why Invest in Chinese Filtration Solutions?

- Innovation & Technology Adoption: Chinese manufacturers are quick to adopt and refine cutting-edge technologies, offering sophisticated solutions like high-performance fiberglass media and smart filtration systems that rival global standards.

- Competitive Pricing & Value: Leveraging efficient manufacturing processes and a robust supply chain, Chinese companies often provide cost-effective solutions without compromising on quality or performance, leading to a superior return on investment.

- Diverse Product Portfolio: From standard filter paper to highly specialized fiberglass filter cloth, the range of products available ensures that specific application needs can be met, often with customizable options.

- Scalability & Responsiveness: Chinese manufacturers are well-equipped to handle large-scale orders and demonstrate agility in responding to market changes and client demands, making them reliable partners for growing businesses.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Thorough Due Diligence: Research potential partners extensively, checking certifications, quality control processes, and client testimonials. Attending events like ProPak Asia provides an excellent opportunity for face-to-face evaluation.

- Clear Communication & Specifications: Provide unambiguous technical specifications and performance requirements. Establish clear communication channels and, if possible, consider engaging third-party inspection services.

- Focus on Long-Term Relationships: Seek partners interested in long-term collaboration. Building trust and a mutual understanding of business objectives leads to more successful and sustainable partnerships.

- Understand Certifications & Standards: Ensure that products comply with relevant international and local industry standards (e.g., ISO, CE, FDA for specific applications).

- Visit Facilities (if possible): A factory visit offers invaluable insight into a manufacturer's production capabilities, quality control, and commitment to innovation, especially for specialized products like fiberglass filter media.

Future-Proof Strategies:

- Embrace Advanced Materials: Prioritize suppliers offering next-generation filter media, such as high-efficiency fiberglass media, for superior performance and longevity.

- Invest in Smart Systems: Integrate smart monitoring and predictive maintenance features into your filtration infrastructure to enhance operational efficiency and reduce unforeseen costs.

- Prioritize Sustainability: Align your filtration choices with your corporate sustainability goals by selecting reusable, regenerable, or environmentally friendly filter media and equipment.

- Diversify Supply Chains: Avoid over-reliance on a single supplier. A diversified approach, including reliable Chinese manufacturers, can enhance supply chain resilience.

By adopting these strategies, businesses can effectively leverage the strengths of Chinese manufacturers, ensuring their filtration solutions are robust, efficient, and prepared for future challenges.

Conclusion: A Vision for a Cleaner Tomorrow

ProPak Asia continues to serve as an indispensable arena for the global filter paper and filtration equipment market, showcasing the relentless pursuit of innovation and efficiency. The prominent presence of Chinese manufacturers, led by forward-thinking companies like ANYA FILTER MEDIA CO., LTD, underscores their pivotal role in shaping the industry's future. From advanced fiberglass media to comprehensive sustainable solutions, their contributions are vital for addressing the complex filtration challenges of our time.

For B2B decision-makers, the message is clear: the path to optimized industrial processes, environmental compliance, and enhanced operational longevity lies in embracing cutting-edge filtration technologies and forming strategic partnerships. Chinese manufacturers are not just suppliers; they are crucial partners in navigating the evolving demands for cleaner air, purer water, and safer products.

To discover how advanced filtration solutions, particularly high-efficiency fiberglass filter media, can transform your operations, we invite you to explore the offerings of ANYA FILTER MEDIA CO., LTD.

Post time: Sep-29-2025