Introduction to Non-Woven Air Filter Media

In the realm of industrial and commercial air filtration, the demand for high-performance, cost-effective, and sustainable solutions is ever-increasing. Central to meeting these stringent requirements is the innovation in filter media technology. Among the most versatile and efficient options available today is non woven air filter media. This advanced material, engineered from synthetic fibers, offers superior particulate capture, low pressure drop, and extended service life, making it indispensable across a multitude of applications from HVAC systems to complex industrial processes. Its unique structural properties allow for precise control over filtration efficiency and airflow characteristics, directly impacting energy consumption and indoor air quality.

Non-woven media represents a significant leap forward from traditional filtration materials, providing enhanced performance and adaptability for diverse environmental and operational challenges. The continuous evolution of non-woven fabric air filter technologies ensures that industries can maintain cleaner environments, protect sensitive equipment, and comply with increasingly strict air quality regulations.

Current Industry Trends and Market Drivers

The global market for air filtration is experiencing robust growth, driven by several key trends. Increasing awareness regarding indoor air quality (IAQ) and outdoor air pollution, coupled with stricter environmental regulations, are paramount. Industrial sectors are prioritizing energy efficiency and reduced operational costs, directly influencing the choice of filtration media. The advent of advanced materials and manufacturing techniques is leading to the development of more efficient and durable non woven air filter media, offering superior performance characteristics.

- Sustainability Focus: Growing demand for recyclable, biodegradable, or long-lasting non woven media that minimizes environmental impact.

- High-Efficiency Particulate Air (HEPA) and Ultra-Low Particulate Air (ULPA) Alternatives: Development of advanced synthetic media achieving near-HEPA performance with lower pressure drop for energy savings.

- Smart Filtration Systems: Integration of sensors and IoT for real-time monitoring of filter performance, predictive maintenance, and optimized replacement cycles.

- Antimicrobial and Antiviral Properties: Enhanced filter media with coatings or inherent properties to mitigate biological contaminants, crucial in healthcare and public spaces.

- Customization and Specialization: Increasing need for tailored non woven media solutions for niche applications, requiring specific fiber blends, pore sizes, and surface treatments.

Manufacturing Process of Non-Woven Air Filter Media

The production of non woven air filter media is a sophisticated multi-stage process, leveraging advanced textile technologies to create highly efficient filtration matrices. Unlike woven fabrics, non-wovens are produced by bonding fibers together without the need for weaving or knitting, offering distinct advantages in terms of porosity control and material versatility.

Detailed Process Flow:

-

Fiber Selection and Preparation:

High-quality synthetic fibers such as polypropylene, polyester, or bicomponent fibers are chosen based on the desired filtration efficiency, temperature resistance, chemical compatibility, and mechanical strength. These fibers are often extruded in-house or sourced, then opened and blended to achieve homogeneity.

-

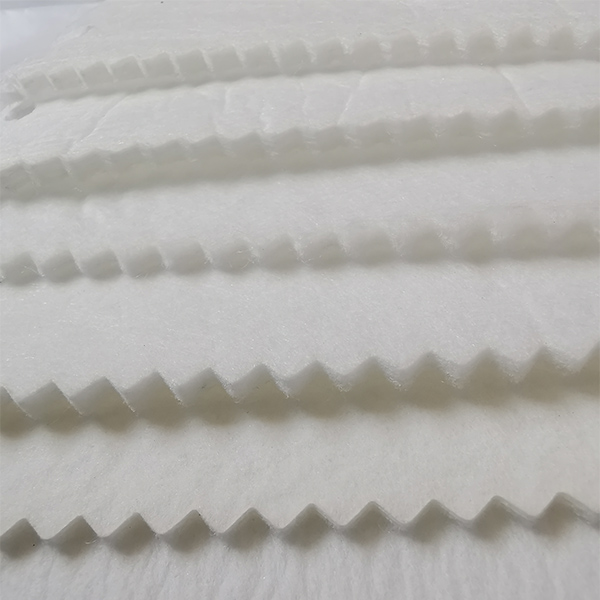

Web Formation:

The prepared fibers are formed into a web or mat. Common methods include:

- Spunbond: Polymer granules are melted and extruded through spinnerets to form continuous filaments, which are then laid randomly onto a conveyor belt and thermally bonded. This method produces strong, durable media.

- Meltblown: Molten polymer is extruded through fine dies into high-velocity air streams, attenuating the fibers into very fine filaments (microfibers) that are then collected on a screen. This creates media with excellent barrier and filtration properties due to the small fiber diameter and high surface area.

- Carding/Air-laid: Staple fibers are opened, individualized, and then formed into a web using mechanical (carding) or aerodynamic (air-laid) processes. These webs are then typically bonded.

-

Web Bonding:

To impart mechanical integrity and durability, the fiber web undergoes a bonding process:

- Thermal Bonding: Heat and pressure are applied to soften and fuse the fibers at their crossover points, particularly effective with thermoplastic fibers.

- Chemical Bonding: Binders (e.g., acrylic emulsions) are applied to the web and then cured, creating strong fiber-to-fiber bonds.

- Mechanical Bonding (Needle Punching, Hydroentanglement): Fibers are mechanically entangled using barbed needles or high-pressure water jets, respectively.

-

Finishing Treatments:

Post-bonding, the non woven media can receive various treatments to enhance its performance:

- Electret Charging: Imparting an electrostatic charge to enhance filtration efficiency of fine particles without significantly increasing pressure drop.

- Surface Coatings: Applying hydrophobic, oleophobic, antimicrobial, or fire-retardant finishes.

- Calendaring: Passing the media through heated rollers to control thickness, density, and surface smoothness.

-

Slitting and Packaging:

The finished non woven media is then cut to specified widths and lengths, wound onto rolls, and packaged for shipment to filter manufacturers.

The entire process is governed by strict quality control, adhering to international standards such as ISO 16890 for filter efficiency and ASTM F2101 for bacterial filtration efficiency, where applicable. The resulting non woven media offers an extended service life due to its high dust holding capacity and robust construction. Target industries include HVAC, automotive, medical, and general industrial filtration, where energy saving and particle retention are critical.

Technical Specifications and Performance Parameters

Understanding the technical specifications of non woven air filter media is crucial for selecting the optimal material for a given application. Key parameters dictate efficiency, airflow, and longevity.

Typical Non-Woven Filter Media Specifications:

| Parameter | Description | Typical Range | Standard |

|---|---|---|---|

| Basis Weight | Mass per unit area, indicating material density. | 30 - 300 gsm (grams per square meter) | ISO 536 |

| Thickness | Measure of media caliper, influencing pressure drop. | 0.2 - 5.0 mm | ISO 9073-2 |

| Air Permeability | Volume of air passing through unit area at specific pressure drop. | 50 - 2000 L/m²/s | ISO 9237 |

| Initial Pressure Drop | Resistance to airflow across clean media at a given face velocity. | 10 - 150 Pa (at 0.25 m/s) | ISO 16890, EN 779 |

| Filtration Efficiency | Ability to capture particles of a specific size. Ranges from coarse to fine. | ePM10 50% to ePM1 90%+ | ISO 16890 (ePM1, ePM2.5, ePM10) |

| Dust Holding Capacity (DHC) | Total amount of dust a filter can hold before reaching terminal pressure drop. | 100 - 600 g/m² | ISO 16890, EN 779 |

| Tensile Strength | Resistance to breaking under tension. Important for filter integrity. | 50 - 500 N/5cm | ISO 9073-3 |

| Temperature Resistance | Maximum operating temperature the media can withstand. | 80°C to 150°C (depending on polymer) | Manufacturer Specific |

These parameters are critical for specifying the performance of non woven media within a filter system. For example, a lower initial pressure drop directly translates to reduced energy consumption for HVAC fans, while a higher Dust Holding Capacity prolongs the filter's service life, minimizing replacement frequency and associated labor costs. Adherence to standards like ISO 16890 (which replaced EN 779) ensures a uniform global approach to evaluating filter performance based on particulate matter (PM) fractions.

Application Scenarios Across Diverse Industries

The versatility and customizable nature of non woven air filter media make it suitable for an expansive array of application scenarios across virtually all industrial and commercial sectors requiring air quality control.

-

HVAC Systems (Commercial & Residential):

Utilized in pre-filters, panel filters, and bag filters (e.g., F5-F9 according to EN 779 or ePM10 50% to ePM1 80% under ISO 16890) to protect HVAC equipment, improve indoor air quality, and reduce energy consumption. Essential for offices, hospitals, schools, and shopping centers.

-

Automotive Industry:

Forms the core of engine air intake filters, cabin air filters, and fuel filters. In cabin air filters, multilayer non woven media effectively captures pollen, dust, soot, and even fine particulate matter to ensure passenger comfort and health.

-

Industrial Filtration:

Critical for dust collection systems, paint spray booths, pharmaceutical manufacturing, food processing, and chemical industries. Customized non woven media can handle specific particulate types, high temperatures, or chemical exposures.

-

Medical and Healthcare Facilities:

Used in operating rooms, isolation wards, and laboratories where ultra-clean air is paramount. Advanced non woven fabric air filter types can achieve high bacterial and viral filtration efficiencies (BFE/VFE), protecting both patients and medical staff.

-

Cleanrooms:

As pre-filters to extend the life of HEPA/ULPA filters, non woven media plays a crucial role in semiconductor manufacturing, biotechnology, and aerospace industries, maintaining stringent particle counts.

-

Power Generation (Turbine Inlet Filtration):

High-efficiency, robust non woven media protects gas turbines from particulate ingestion, preventing erosion and fouling, thereby maintaining optimal performance and extending turbine service life.

Technical Advantages of Non-Woven Air Filter Media

The engineered structure of non woven air filter media provides a range of significant technical advantages over traditional filtration materials, directly translating into operational efficiencies and cost savings for end-users.

-

High Filtration Efficiency:

Through precise control of fiber diameter, web structure, and electret charging, non woven media can achieve filtration efficiencies from MERV 8 to MERV 16 (ASHRAE 52.2) or ePM10 to ePM1 (ISO 16890), effectively capturing a broad spectrum of airborne particulates, including fine dust, pollen, spores, and even bacteria and viruses. Modern non woven media can even rival some HEPA filters in specific applications.

-

Low Initial Pressure Drop:

The open, optimized pore structure of non woven media allows for high airflow with minimal resistance. This translates to significantly reduced energy consumption for fans and blowers in HVAC and industrial systems, leading to substantial operational cost savings over the filter's lifetime.

-

High Dust Holding Capacity (DHC):

The deep, tortuous path created by the non-woven fiber matrix allows it to accumulate a larger volume of dust before reaching its terminal pressure drop. This extends the filter's service life, reducing maintenance frequency, labor costs, and waste generation.

-

Robust Mechanical Strength and Durability:

Synthetic non woven media exhibits excellent tensile strength and resistance to tearing, ensuring structural integrity even under demanding airflow conditions or during handling. This prevents media breakage and particulate bypass.

-

Chemical and Moisture Resistance:

Many synthetic fibers used in non woven media (e.g., polypropylene, polyester) offer inherent resistance to moisture and a wide range of chemicals, making them suitable for applications in humid or chemically aggressive environments.

-

Versatility and Customization:

Non woven media can be tailored in terms of fiber type, basis weight, thickness, density, and surface treatments to meet specific filtration requirements, including high temperature, antimicrobial properties, or fire retardancy.

Vendor Comparison: Key Differentiators in Non-Woven Media

Choosing the right supplier for non woven media is a critical decision for filter manufacturers and industrial end-users. While many vendors offer non woven media, key differentiators in their product portfolios and services can significantly impact performance, cost-efficiency, and supply chain reliability.

Comparison Factors for Non-Woven Air Filter Media Vendors:

| Feature | Vendor A (Focus on Cost) | Vendor B (Focus on Performance/Innovation) | Vendor C (Focus on Customization/Niche) |

|---|---|---|---|

| Product Range | Standard polyester/polypropylene, MERV 8-11. | Advanced multi-layer media, electret-charged, MERV 13-16, ePM1 capable. | Specialty blends (e.g., glass fiber, activated carbon), high-temp resistant. |

| R&D Investment | Limited, primarily process optimization. | High, focusing on new fiber technologies, efficiency improvements, and energy savings. | Moderate, focused on application-specific material development. |

| Quality Certifications | ISO 9001. | ISO 9001, ISO 14001, rigorous internal testing to ISO 16890. | ISO 9001, specific industry certifications (e.g., FDA compliance for medical). |

| Technical Support | Standard product data sheets. | Application engineering support, performance modeling, and joint development. | Custom formulation, prototyping services, and specialized testing. |

| Lead Time & Logistics | Standard 4-6 weeks, regional distribution. | Efficient supply chain, 3-4 weeks, global logistics. | Variable for custom orders, often project-based. |

| Pricing Model | Competitive unit pricing for high volume. | Value-based pricing, emphasizing TCO (Total Cost of Ownership) benefits. | Project-based pricing, reflecting R&D and specialized production. |

A thorough evaluation of these factors, beyond just the initial cost per square meter, allows businesses to align with a vendor that best supports their long-term strategic goals for performance, sustainability, and market differentiation in their products using non woven air filter media.

Customized Solutions and Expertise

The diverse requirements of modern filtration applications necessitate more than off-the-shelf solutions. Leading manufacturers of non woven air filter media excel in providing highly customized products tailored to specific operational demands, environmental conditions, and performance metrics.

Our Approach to Customization:

-

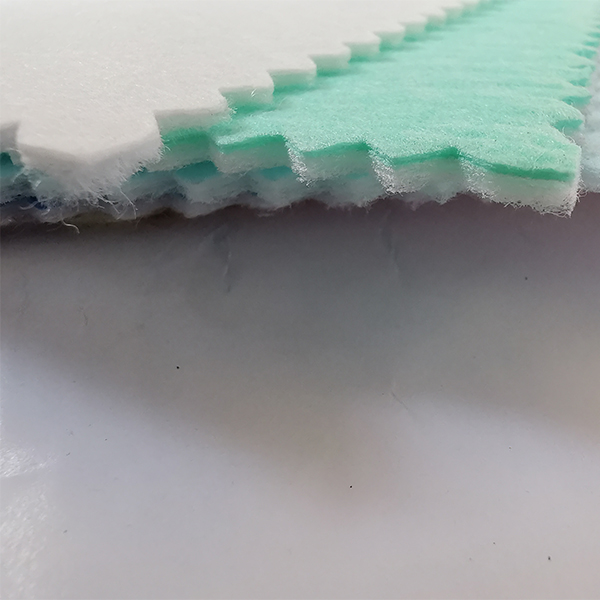

Material Blending and Fiber Selection:

Development of proprietary blends of polypropylene, polyester, glass fibers, or specialty polymers to achieve desired thermal stability, chemical resistance, or mechanical properties. For instance, combining coarse and fine fibers in a gradient structure to optimize both dust holding capacity and fine particle filtration.

-

Structural Engineering:

Tailoring the media's basis weight, thickness, density, and loft to precisely control airflow resistance and filtration efficiency. Multi-layer media constructions (e.g., pre-filter layer + fine filtration layer) can be engineered for staged filtration.

-

Advanced Treatments and Coatings:

Application of specialized coatings for enhanced functionalities, such as hydrophobic treatments for moisture resistance, oleophobic finishes for oil mist filtration, antimicrobial agents for biological growth inhibition, or flame retardants for safety-critical applications.

-

Electret Technology Optimization:

Precise control over electret charging levels to maximize electrostatic filtration efficiency for sub-micron particles while maintaining minimal pressure drop, which is particularly beneficial in high-efficiency HVAC and respirator applications.

-

Form Factor and Finishing:

Media can be supplied in various widths, roll lengths, or pre-cut sheets, with options for lamination, pleatability enhancements, or special edge treatments to facilitate seamless integration into specific filter designs and manufacturing processes.

Our team of materials scientists and filtration engineers works collaboratively with clients, utilizing advanced simulation tools and in-house testing facilities to develop and validate custom non woven media solutions. This deep expertise ensures that the final product not only meets but exceeds the required performance criteria, offering a competitive edge.

Application Case Studies & Customer Success

Real-world applications demonstrate the tangible benefits of high-quality non woven media. Our commitment to expertise and collaboration has resulted in significant successes for our partners.

Case Study 1: HVAC System Upgrade for a Pharmaceutical Plant

Challenge: A major pharmaceutical manufacturer required improved air cleanliness in their processing areas to comply with increasingly stringent FDA regulations, while also battling high energy costs from their existing MERV 11 filters.

Solution: We collaborated to develop a custom multilayer non woven media, incorporating electret technology. This specialized non woven media was engineered to achieve MERV 14 efficiency with an initial pressure drop comparable to their previous MERV 11 media.

Result: The client achieved a 25% reduction in particulate counts, meeting new regulatory benchmarks. Concurrently, due to the optimized pressure drop, their HVAC system's energy consumption for air handling units decreased by 18%, leading to estimated annual savings of $75,000 in electricity costs. Filter change-out frequency also extended by 30% due to enhanced dust holding capacity.

Case Study 2: Extending Turbine Life in a Power Generation Facility

Challenge: A gas turbine power plant in a dusty desert environment experienced premature erosion of turbine blades and frequent unscheduled shutdowns due to fine dust ingress, despite using standard F8 grade filter elements.

Solution: We engineered a robust non woven media specifically designed for turbine inlet filtration, featuring high mechanical strength and an ePM2.5 75% efficiency rating (ISO 16890), significantly higher than their previous media. The non woven media was also treated for enhanced moisture repellency to combat occasional heavy rainfall.

Result: Post-implementation, the plant reported a 40% reduction in turbine blade erosion rates over 12 months. This led to a projected increase of 2 years in the turbine's operational life before major overhaul, representing millions in savings and significantly reducing downtime. The enhanced dust holding capacity also extended filter life by 50%, reducing maintenance needs.

Authoritativeness and Trustworthiness

Our commitment to quality, compliance, and customer satisfaction underpins our position as a trusted provider of non woven media solutions.

Quality Assurance & Certifications:

- ISO 9001:2015 Certified: Demonstrating our adherence to rigorous quality management systems in design, development, production, and service.

- ISO 14001:2015 Certified: Underlining our commitment to environmental management and sustainable manufacturing practices.

- Compliance with Global Standards: Our products are tested and validated against international filtration standards including ISO 16890, EN 779, and ASHRAE 52.2, ensuring verifiable performance data.

- Strategic Partnerships: We collaborate with leading research institutions and industry bodies to stay at the forefront of filtration technology, ensuring our non woven media solutions are continuously optimized.

Frequently Asked Questions (FAQ):

- Q: What is the typical lead time for custom non woven media orders?

- A: Standard lead time for custom orders is generally 4-6 weeks from confirmed specifications and order placement. Expedited options may be available depending on material availability and production schedules.

- Q: What is your warranty policy for non woven filter media?

- A: We offer a standard 12-month warranty against manufacturing defects from the date of shipment, provided the media is stored and used under recommended conditions. Specific performance warranties are detailed in product data sheets and contractual agreements.

- Q: How do you handle customer support and technical assistance?

- A: Our dedicated technical support team is available via phone and email during business hours. We provide comprehensive pre-sales consultation, application engineering support, and post-sales troubleshooting. On-site technical visits can be arranged for complex projects or issues.

- Q: Can your non woven media be supplied with specific flame retardancy ratings?

- A: Yes, we offer non woven media that can be engineered to meet various flame retardancy standards, such as UL 94 V-0 or DIN 53438 (F1), depending on the application requirements. Please specify your needs during the inquiry process.

Conclusion

The continuous innovation in non woven media technology underscores its critical role in modern air filtration. From enhancing energy efficiency in HVAC systems to safeguarding critical industrial processes and ensuring public health, advanced non woven fabric air filter solutions are integral to addressing today's complex air quality challenges. By focusing on detailed technical specifications, robust manufacturing processes, and tailored solutions, businesses can leverage the full potential of these materials to achieve superior performance, extended service life, and significant operational savings. Our commitment to quality, research, and client-centric solutions positions us as a reliable partner in delivering the next generation of filtration excellence.

References

- International Organization for Standardization (ISO). ISO 16890:2016 - "Air filters for general ventilation - Part 1: Technical specifications, requirements and classification system based upon particulate matter efficiency (ePM)."

- ASHRAE Standard 52.2-2017 - "Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size." American Society of Heating, Refrigerating and Air-Conditioning Engineers.

- European Committee for Standardization (CEN). EN 779:2012 - "Particulate air filters for general ventilation - Determination of the filtration performance." (Superseded by ISO 16890 for new installations, but referenced for existing systems).

- Nonwovens Industry Magazine. "Global Nonwovens Market Outlook." www.nonwovens-industry.com

- Journal of Engineered Fibers and Fabrics. Various articles on nonwoven filtration media development and performance. www.jeffjournal.org

Post time: Sep-15-2025