Filters Accessories: the small parts that make filtration systems work

If you’ve ever debugged a filter line at 2 a.m., you know the “little things” aren’t little. End caps, PU glue, frames, gaskets, meshes—these are the quiet heroes. I toured the operation in Shijiazhuang (No.580 Gongnong Road, Hebei) and, to be honest, the appeal is the one-stop procurement approach. You grab what you need, matched, tested, and ready.

What’s in scope

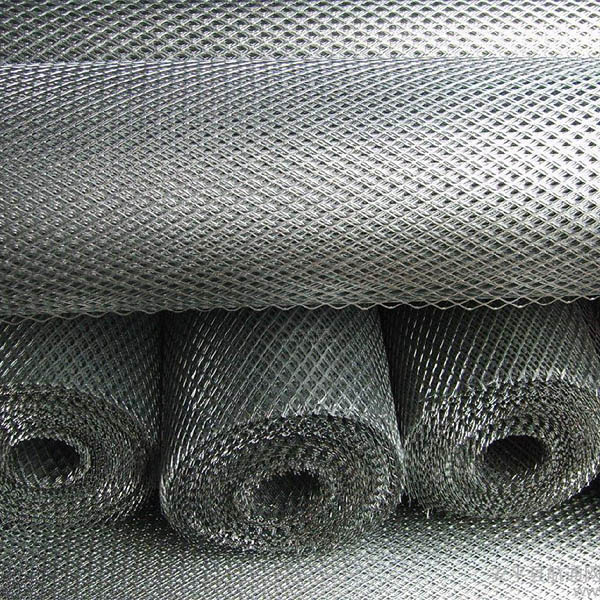

PU glue and adhesives, plastic molds for PU filters, filter end caps (galv steel, aluminum, tinplate), gaskets (NBR, EPDM, silicone), frames (ABS, PP, PC, steel), metal wire mesh, and the fiddly bits many customers say are hard to source consistently. These Filters Accessories aim at automotive, HVAC, dust collection, pharma, and food plants—where downtime is expensive.

Specification snapshot

| Accessory | Material | Size Range | Temp/Fluid Rating | Service Life |

|---|---|---|---|---|

| PU Glue/Adhesive | 2K PU, epoxy, hot-melt | Viscosity-tuned | Oil/water compatible (ISO 2943), up to ≈120°C | ≈2–5 years; real-world use may vary |

| End Caps | Galv steel, Al, tinplate | 40–450 mm Ø | Salt spray ASTM B117 ≥72 h | ≈5–10 years |

| Gaskets | NBR, EPDM, silicone (ASTM D2000) | Custom profiles | -30 to 200°C, fuels/chemicals—ask for spec | ≈3–8 years |

Process flow and QC (short version)

Materials: certified steels, Al coils, engineering plastics, elastomers, PU components. Methods: punching, deep-draw, injection molding, PU foaming, die-cutting, CNC trimming.

Testing: dimensional checks, pull/peel adhesion, salt spray (ASTM B117), gasket hardness and compression set (ASTM D2000), fluid compatibility (ISO 2943). For system fit, filters later validated by ISO 16890/ASHRAE 52.2; HEPA frames matched to EN 1822 classes where relevant.

Traceability: lot coding; RoHS/REACH declarations available. Lead times: around 10–25 days depending on tooling.

Where they’re used

- HVAC panels, bag filters, and V-banks in commercial buildings.

- Automotive oil/air/fuel elements—caps, center tubes, end seals.

- Dust collectors in cement, steel, and woodworking (high-vibe duty).

- Food & beverage and pharma—gaskets, stainless meshes on request.

- Gas turbine prefilters—robust frames, corrosion-focused coatings.

Industry trend check

Two things: lighter frames to cut logistics CO2, and adhesives that tolerate biofuels and synthetic oils. Surprisingly, some buyers still chase lowest-cost caps and then spend more fixing leaks. The total cost of poor sealing is… not small.

Vendor comparison (abbreviated)

| Criteria | Anya Filters Accessories | Vendor A | Vendor B |

|---|---|---|---|

| MOQ | Flexible, project-based | High | Mid |

| OEM/Tooling | In-house molds; rapid tweaks | Outsourced | Partial |

| Compliance | RoHS/REACH docs on request | Limited | Mixed |

| Lead Time | ≈10–25 days | ≈25–45 days | ≈20–35 days |

Customization and engineering notes

CAD-to-tool turnaround is brisk; gasket durometers 40–70 Shore A; mesh from 20–200 mesh, stainless options for corrosive air. Adhesives are tuned to cure windows and rheology that suit your line speed. It seems that design-for-assembly is the real win here.

Field results

Case 1 (HVAC retrofit): switched to higher compression-set-resistant gaskets; leakage dropped from 3.5% to 0.8% (ISO 16890 rig), payback ≈4 months.

Case 2 (diesel fuel filters): epoxy end-cap adhesive replaced with PU hybrid; peel strength up 28%, reject rate down from 2.1% to 0.6%.

Compliance and documentation

Materials can ship with RoHS and REACH declarations; food-contact gaskets upon request with FDA CFR 21 references. Final filter validation per ISO 16890 or ASHRAE 52.2, and HEPA per EN 1822—accessories are built to not be the bottleneck. Customers report smoother audits, which I guess is the whole point.

Customer feedback: “Seals seat the first time,” “Nice balance of stiffness vs. weight on frames,” and, my favorite, “We stopped babysitting glue.”

Citations

- ISO 16890: Air filters for general ventilation (International Organization for Standardization)

- ASHRAE Standard 52.2: Method of Testing General Ventilation Air-Cleaning Devices (ASHRAE)

- EN 1822-1: High efficiency air filters (EPA, HEPA, ULPA) (CEN)

- ASTM D2000: Standard Classification System for Rubber Products in Automotive Applications (ASTM International)

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus (ASTM International)

- ISO 2943: Hydraulic fluid power—Compatibility of materials with fluids (ISO)

- RoHS Directive 2011/65/EU (European Union)

- REACH Regulation (EC) No 1907/2006 (European Union)

Post time: Oct-23-2025