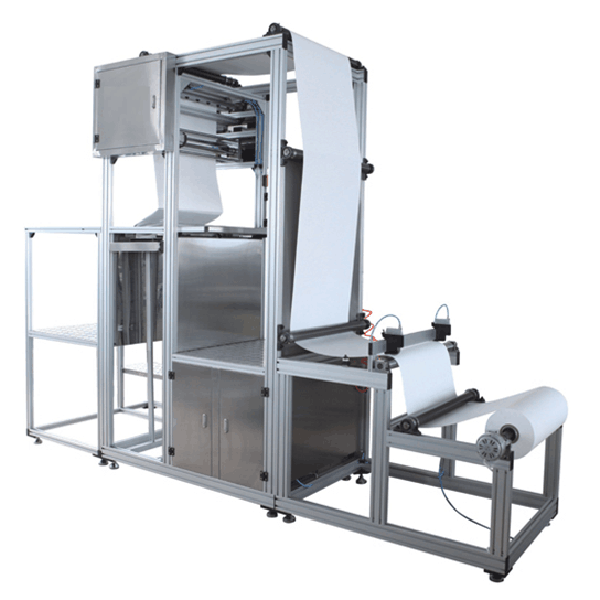

A Practical Look at the Modern filter making machine

If you’ve toured a filter plant lately, you’ve seen it: shorter changeovers, quieter drives, smarter controls. The vibe is clear—productivity without sacrificing accuracy. That’s where a well‑specced filter making machine earns its keep. To be honest, many customers tell me they care less about the brochure and more about uptime, pleat consistency, and traceable QA. Same here.

Market snapshot and what’s changing

Demand is nudged by stricter indoor air quality rules (ISO 16890), EV cabin comfort, and upgrades in cleanrooms. Surprisingly, the biggest ROI I’ve seen comes from smarter PLCs that cut setup time and keep pleat pitch stable even when media thickness varies. Real-world use may vary, of course, but the pattern holds.

Key specs (field-proven, not just marketing)

| Parameter | Typical Value |

|---|---|

| Automation | Fully or semi‑automatic |

| Pleat pitch range | ≈ 3–60 mm (media-dependent) |

| Max media width | ≈ 1,000–1,200 mm |

| Line speed | Up to ≈ 20–35 m/min |

| Pitch accuracy | ±0.2–0.3 mm in stable conditions |

| Control system | PLC + touchscreen HMI |

Process flow and materials

- Media: paper, nonwoven, fiberglass, synthetic mesh (mix and match, depending on target class).

- Steps: unwinding → tension control → preheating/scoring → pleating → hot‑melt or PU bead metering → cutting → frame assembly → curing → in‑line QC.

- Testing: ISO 16890 (HVAC), EN 1822 (HEPA), ASHRAE 52.2 (MERV), ISO 5011 (engine intake), ISO 29461 (turbomachinery).

- Service life: typically 6–18 months HVAC; 10k–25k km for engine air—depends on dust load and maintenance.

- Industries: building HVAC, automotive, cleanrooms, paint booths, food & beverage, gas turbines, dust collection.

Sample test data from recent runs: MERV 13 (≈ ePM1 65%) at initial ΔP ≈ 120 Pa; HEPA H13 99.95% MPPS per EN 1822 with leakage ≤ 0.01%; endurance run 8h showed pleat height drift under 0.15 mm. I guess the headline is stability under thermal load.

Vendor comparison (quick, honest look)

| Vendor | Customization | Lead time | Certs/Standards | After‑sales |

|---|---|---|---|---|

| Anya Filter Media | High (tooling, pitch, media paths) | ≈ 6–10 weeks | ISO 9001; supports ISO 16890/EN 1822 testing | Remote + on‑site, spares stocked |

| OEM B (generic) | Medium | ≈ 10–14 weeks | ISO 9001 | Remote primarily |

| Integrator C (regional) | Medium‑High | ≈ 8–12 weeks | Depends by region | On‑site, limited spares |

Customization and controls

- PLC with touchscreen; recipe management for filter types/sizes.

- Swap‑friendly pleat tools; hot‑melt patterns adjustable; optional rotary or guillotine cutters.

- Works with paper, nonwoven, fiberglass, mesh; integrates with pre/post modules (PU potting, frame gluing).

- Address: No.580 Gongnong Road, Shijiazhuang City 050000, Hebei, P.R. China.

Use cases and feedback

- HVAC OEM: switched to a filter making machine with auto tension control; throughput +28%, scrap −15%. “Changeovers feel… calmer,” their line lead said.

- Automotive supplier: cabin filter line mixing meltblown and cellulose; achieved MERV 12 targets with ΔP spread reduced by ≈ 18% over previous setup.

Final thought—spec sheets are nice, but watch a live run. The consistency in pleat pitch and bead placement tells you everything about long-term cost.

References

- ISO 16890 series: Air filters for general ventilation.

- EN 1822-1:2019: High efficiency air filters (EPA, HEPA, ULPA).

- ASHRAE Standard 52.2-2017: Method of Testing General Ventilation Air-Cleaning Devices.

- ISO 5011:2014: Inlet air cleaning equipment for internal combustion engines.

- ISO 29461-1:2021: Air intake filtration for gas turbines and compressors.

Post time: Oct-17-2025