The Pivotal Role of filters accessories in Modern Industrial Filtration

In the intricate landscape of industrial and commercial filtration, while the core filter media often garners the primary attention, the unsung heroes are undeniably the vital filtration components. These critical elements—ranging from precise pressure gauges and accurate flow meters to robust valve assemblies, durable housings, and advanced sealing elements—are indispensable for the optimal function, longevity, and efficiency of any filtration system. Without precisely engineered accessories, even the most advanced filter media would struggle to perform at its peak, leading to inefficiencies, increased operational costs, potential system failures, and non-compliance with critical industry regulations.

This comprehensive guide delves into the intricate world of industrial filters accessories, exploring their foundational technical specifications, advanced manufacturing processes, diverse application scenarios across various heavy and light industries, and the strategic advantages they impart in demanding operational environments. We aim to illuminate how these often-overlooked components are not just supplementary items but fundamental pillars supporting the integrity, operational safety, and long-term economic viability of modern filtration systems. Through a blend of technical insights, real-world examples, and data-driven perspectives, we underscore their significance for engineers, procurement specialists, and facility managers striving for superior filtration outcomes and optimized total cost of ownership.

Navigating Current Industry Trends in Filtration Accessories

The market for filtration components is constantly evolving, driven by global shifts towards sustainability, digitalization, and enhanced operational efficiency. Key trends include the increasing demand for smart filtration systems equipped with advanced sensors and IoT connectivity, allowing for real-time monitoring of critical parameters such as pressure differentials, flow rates, and filter lifespan. This shift enables predictive maintenance, significantly reducing unplanned downtime, extending filter lifespan, and optimizing resource allocation.

Another prominent trend is the relentless pursuit of materials with superior chemical and thermal resistance, along with enhanced mechanical properties, especially for applications in highly aggressive chemical environments, high-pressure systems, or ultra-purity processes. The adoption of advanced stainless steel alloys (e.g., Duplex Stainless Steel for enhanced strength and corrosion resistance), specialized polymers (e.g., PEEK, PTFE for extreme chemical inertness), and innovative ceramic coatings is becoming increasingly common to extend the service life of filters accessories. Furthermore, there's a growing emphasis on modular, compact designs that facilitate easier installation, maintenance, and system scalability, providing greater operational flexibility and reducing physical footprint. The integration of components that actively contribute to higher energy efficiency, such as advanced low-pressure-drop valves, optimized housing designs with improved internal flow dynamics, and smart sensor integration for flow optimization, is also a critical market driver, reflecting broad industry efforts to minimize energy consumption and environmental impact while maximizing throughput.

Key Technical Parameters for Selecting Robust Filters Accessories

The performance and reliability of a filtration system are intrinsically linked to the precise selection of its key components. Understanding their core technical parameters is essential for engineers and system designers to ensure compatibility, efficiency, and longevity. These parameters define the operational boundaries and suitability for specific applications.

Critical Parameters Overview:

- Material Compatibility: Crucial for preventing corrosion and ensuring chemical resistance. Common materials include SS304, SS316L, PVC, CPVC, PP, and PTFE, selected based on the fluid's chemical composition and temperature. Understanding the Material Traceability Reports (MTRs) is vital for regulated industries.

- Pressure Rating: The maximum safe operating pressure, typically specified in PSI or Bar. Accessories must withstand peak system pressures, including potential surges, validated through hydrostatic testing.

- Temperature Range: The minimum and maximum temperatures the accessory can safely operate within. This affects material selection (e.g., gaskets, O-rings) and overall structural integrity, especially for continuous high-temperature processes.

- Flow Rate Capacity: The maximum volume of fluid the accessory can handle without excessive pressure drop, measured in GPM or m³/hr. Optimizing this parameter ensures minimal energy consumption by pumps.

- Connection Type and Size: Standard connections include NPT, BSP, flange, or sanitary clamp, ensuring seamless integration into existing piping systems. Sizes vary widely based on system scale and required throughput.

- Certification and Standards: Compliance with industry standards like ASME Boiler and Pressure Vessel Code, ISO, ANSI, FDA (for food/beverage/pharmaceutical), or NSF (for potable water) is vital for safety, regulatory adherence, and market acceptance.

- Pressure Drop: The inherent resistance an accessory adds to fluid flow, impacting pump efficiency and overall energy consumption. Minimizing pressure drop is a key design objective for energy-efficient systems.

Typical Specifications Table for Filters Accessories

| Parameter | Description | Common Range/Value | Typical Application Example |

|---|---|---|---|

| Material | Construction material for housings, valves, gauges. | SS304, SS316L, PVC, PP, PVDF, Cast Iron, Bronze | SS316L for chemical/food, PVC for general water treatment |

| Max Operating Pressure | Highest pressure accessory can withstand safely. | Up to 250 PSI (17 Bar) for standard, 1000 PSI+ for high-pressure | High-pressure RO systems, industrial process lines |

| Operating Temperature | Temperature range for continuous operation. | -20°C to 120°C (depending on material, seals) | Hot water loops, chilled water systems |

| Connection Size | Inlet/outlet connection diameters. | 1/2" NPT to 12" Flange (DN15 to DN300) | Residential water filters (1"), large industrial plants (6"+) |

| Flow Rate Capacity | Max flow without excessive pressure drop. | 1 GPM (4 L/min) to 5000+ GPM (19,000+ L/min) | Small lab filters, municipal water treatment |

| Sealing Material | Gasket and O-ring materials. | EPDM, Viton, Buna-N, Silicone, PTFE | Viton for aggressive chemicals, EPDM for general water |

| Surface Finish (for SS) | Internal surface smoothness for hygiene and flow. | Ra 0.8 µm (32 Ra) to Ra 0.25 µm (10 Ra) | Pharmaceutical, Food & Beverage industries |

| Certifications | Adherence to recognized industry standards. | ISO 9001, ASME, CE, FDA, NSF/ANSI 61 | Potable water, regulated industries |

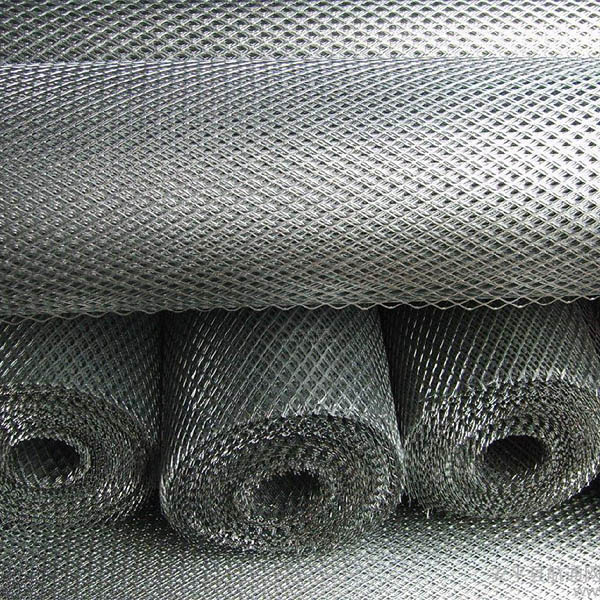

Figure 1: A range of industrial filters accessories, including pressure gauges and valve components.

Precision Engineering: Advanced Manufacturing Processes for Filters Accessories

The reliability and performance of filtration system components are direct results of rigorous manufacturing processes and stringent quality control. Leading manufacturers leverage cutting-edge techniques to ensure components meet precise specifications, withstand harsh operating conditions, and offer extended service life, ultimately contributing to lower total cost of ownership.

Key Manufacturing Processes:

- Material Selection & Preparation: Begins with sourcing high-grade raw materials (e.g., specific stainless steel alloys like SS316L, high-performance polymers like PVDF or PTFE) that comply with international standards such as ASTM or DIN. Comprehensive material traceability is maintained throughout the entire production lifecycle.

- Casting: For complex shapes, especially with metals like cast iron or bronze, precision casting techniques (e.g., investment casting, sand casting) are meticulously used. This allows for intricate internal geometries and efficient material utilization while ensuring structural integrity.

- Forging: For components requiring exceptional strength and impact resistance (e.g., critical valve bodies, high-pressure flanges), forging processes enhance the material's grain structure, eliminating defects and significantly improving mechanical properties and fatigue resistance.

- CNC Machining: Computer Numerical Control (CNC) machining is vital for achieving ultra-tight tolerances and complex geometries for parts like adapter plates, precision fittings, and the intricate internal components of filter housings. This ensures perfect fit, minimal internal flow resistance, and optimal fluid dynamics critical for filtration efficiency.

- Welding: For stainless steel housings and manifolds that demand superior structural integrity and corrosion resistance, advanced welding techniques such as Automated Orbital TIG (Tungsten Inert Gas) welding are meticulously employed. This creates robust, crevice-free, leak-proof joints with minimal heat-affected zones, often followed by a chemical passivation process to enhance the innate corrosion resistance by re-establishing the protective chromium oxide layer.

- Surface Treatment: Includes mechanical polishing (for sanitary applications to achieve specific Ra values), chemical passivation (for stainless steel to remove free iron and enhance corrosion resistance), and protective coating (e.g., epoxy coatings for specific chemical resistance or aesthetics, extending product lifespan).

- Assembly: Meticulous assembly of various components, including seals, gauges, and valves, often in cleanroom environments for high-purity applications, followed by comprehensive final quality checks.

- Testing & Inspection: Each batch undergoes rigorous, multi-stage testing, including hydrostatic pressure testing to verify structural integrity against design pressure, pneumatic leak detection to ensure zero bypass, detailed dimensional inspection using CMM (Coordinate Measuring Machine), and Positive Material Identification (PMI) to confirm alloy composition. Compliance with international standards such as ISO 9001, ASME Boiler and Pressure Vessel Code (Section VIII, Division 1), and ANSI B31.3 is not just a benchmark but a foundational requirement for all our filters accessories.

Figure 2: Precision CNC machining ensures tight tolerances for complex filters accessories.

The typical service life of well-manufactured filtration parts, especially those crafted from SS316L, Duplex Stainless Steel, or high-performance PVDF, can range from 10 to 20 years or even more. This longevity is heavily dependent on the specific application, fluid chemistry, and diligent adherence to recommended maintenance schedules. This extended lifespan directly translates into a significantly lower total cost of ownership (TCO) for industrial operations, making quality accessories a strategic investment.

Figure 3: Advanced welding techniques for durable filter housings and components.

Figure 4: Rigorous quality control checks ensure compliance with international standards for filters and accessories.

Diverse Application Scenarios and Technical Advantages of Filters Accessories

The utility of these critical components spans across a multitude of industries, where they play a paramount role in maintaining fluid purity, protecting expensive downstream equipment, and ensuring overall process efficiency. Their design and material selection are specifically tailored to the demanding conditions, extreme temperatures, and corrosive environments inherent in each sector.

Applicable Industries:

- Petrochemical Industry: Essential for protecting sensitive equipment (e.g., pumps, heat exchangers) from particulate matter in crude oil, refined products, and various chemical streams. Accessories must withstand high pressures, elevated temperatures, and aggressive corrosive fluids, directly contributing to safe, efficient, and uninterrupted operations. For example, differential pressure gauges precisely monitor filter loading to prevent costly downtime and system damage.

- Metallurgy: Utilized in cooling water systems, rolling mill lubrication, and acid pickling lines to efficiently remove contaminants, thereby preventing equipment damage and significantly improving the quality and consistency of the final metallic product. Materials with high abrasion and corrosion resistance are key for these demanding environments.

- Water Treatment & Desalination: Critical in various stages from pre-filtration to advanced Reverse Osmosis (RO) systems and complex wastewater treatment plants. Components like robust membrane housings, specialized pressure vessels, and precise flow control valves are vital. Properly chosen and meticulously maintained filters accessories here ensure efficient membrane operation, extend the life of expensive RO membranes, and guarantee compliance with water quality standards.

- Food & Beverage: Requires stringent sanitary design and FDA-compliant materials for all product contact surfaces. Accessories such as sanitary sample valves, highly polished filter housings (e.g., Ra

- Pharmaceutical: Demands ultra-high purity and absolute sterility. Filtration accessories must be designed for seamless clean-in-place (CIP) and sterilize-in-place (SIP) processes, accompanied by verifiable material certifications, full traceability, and superior surface finishes to prevent contamination and meet strict regulatory compliance (e.g., cGMP).

- Power Generation: Employed extensively in boiler feed water, cooling water circuits, and fuel filtration systems to prevent scaling, corrosion, and equipment wear. High-performance filters accessories enhance power plant efficiency, extend the lifespan of critical turbines and heat exchangers, and significantly improve overall reliability, minimizing costly outages.

Technical Advantages in Typical Applications:

- Energy Efficiency: Optimized housing designs featuring smooth internal surfaces and low-pressure-drop valves minimize energy consumption of pumps by reducing system resistance and turbulence. This translates directly into tangible operational cost savings.

- Corrosion Resistance: Utilization of advanced materials like SS316L, Duplex Stainless Steel, or engineered polymers ensures exceptional longevity and unwavering reliability in highly corrosive or chemically aggressive environments, significantly reducing maintenance and replacement costs.

- Enhanced System Reliability: Accurate pressure gauges, precise flow meters, and integrated smart sensors provide real-time operational data, enabling highly proactive maintenance, identifying potential issues before they escalate, and preventing catastrophic failures. Robust valve systems ensure reliable fluid diversion and isolation, crucial for uninterrupted operation.

- Improved Filtration Performance: Properly sized and expertly sealed filter housings prevent bypass, ensuring that all fluid passes effectively through the filter media, thereby achieving the desired filtration efficacy and contaminant removal rates.

- Reduced Downtime: Modular designs and quick-change mechanisms for filter cartridges, facilitated by well-engineered accessories like quick-opening closures and ergonomic handles, enable faster maintenance and filter replacement, minimizing costly operational interruptions and maximizing uptime.

Figure 5: Filters accessories seamlessly integrated into an industrial water treatment system.

Synergistic Solutions: RO Booster Pumps & RO Consumables Kit Integration

While essential filtration components are critical for various filtration systems, their synergy with complementary solutions like an ro booster pump kit and an ro consumables kit is particularly noteworthy in the context of Reverse Osmosis (RO) systems. RO technology relies on precisely controlled pressure and robust pre-treatment to function effectively and economically, making these integrated solutions indispensable.

The Role of RO Booster Pump Kit:

A ro booster pump kit is fundamental for maintaining the consistent, high operating pressure required for the RO membrane to effectively reject dissolved solids and achieve desired permeate quality. Without adequate and stable pressure, the permeate flow rate would be insufficient, and membrane fouling would accelerate, leading to premature membrane replacement. These kits typically include a high-pressure pump, a precise pressure switch, and often a transformer, ensuring optimal operating conditions for the RO system. When paired with appropriate pressure gauges and accurate flow meters (which are standard filters accessories), operators can accurately monitor pump performance and membrane health, optimizing water production, extending system lifespan, and reducing overall energy consumption.

Integrating with RO Consumables Kit:

An ro consumables kit typically includes essential pre-filters (such as sediment and carbon block filters), post-filters, and sometimes specialized membrane cleaning chemicals. The pre-filters are crucial for protecting the delicate and expensive RO membrane from suspended solids, chlorine, and other contaminants, all of which can cause irreversible damage and reduce membrane efficiency. The proper housings, robust seals, and precise connection fittings (classic filters accessories) for these consumable filters are paramount for preventing leaks and ensuring efficient pre-treatment. For instance, well-sealed filter caps prevent bypass, ensuring all water is properly filtered before reaching the RO membrane. The harmonious operation of filters accessories with the ro booster pump kit and ro consumables kit guarantees that the entire RO system functions at peak efficiency, delivering high-purity water consistently, reliably, and cost-effectively, safeguarding the longevity of the entire system.

Figure 6: A typical ro booster pump kit, essential for optimal RO system performance.

Manufacturer Comparison and Strategic Selection Criteria for Filters Accessories

Choosing the right supplier for critical filtration system components is as crucial as selecting the components themselves. A detailed comparison based on key criteria ensures long-term reliability, cost-effectiveness, and operational peace of mind, significantly impacting the total cost of ownership.

Key Factors for Vendor Evaluation:

- Quality & Certifications: Prioritize manufacturers adhering to rigorous international quality standards like ISO 9001:2015, ASME Boiler and Pressure Vessel Code (Section VIII), or specific industry certifications (e.g., FDA for food contact, NSF for potable water applications). This ensures product integrity, reliability, and regulatory compliance.

- Material Traceability: A reputable manufacturer provides complete material certifications (MTRs) and full traceability for all critical components, especially for pharmaceutical, high-purity, or corrosive chemical applications. This guarantees the specified material properties are met.

- Customization Capabilities: The ability to provide tailored solutions for unique operational requirements, including custom designs, specialized connection types, or the use of exotic materials, is a key differentiator for complex industrial processes.

- Technical Support & Expertise: Access to experienced engineers and robust technical support for initial system design, optimization, troubleshooting, and post-installation support. This is invaluable for complex industrial setups where expertise can prevent costly mistakes.

- Lead Time & Logistics: Reliable delivery schedules and efficient global logistics are critical for timely project completion and avoiding costly operational disruptions. Manufacturers with established supply chains offer greater predictability.

- Warranty & After-Sales Service: Comprehensive warranties and responsive after-sales support reflect a manufacturer's confidence in their product and unwavering commitment to customer satisfaction. This includes availability of spare parts and service engineers.

- Industry Experience: A proven track record of successful projects and long-standing relationships within your specific industry (e.g., oil & gas, pharma, water treatment) signifies deep understanding of your operational challenges. Our company has proudly served diverse industrial sectors for over 20 years, specializing in robust and reliable filtration solutions, building a reputation for innovation, adaptability, and unwavering customer satisfaction. This extensive experience translates into the development of filters accessories that are not just theoretically sound but practically proven in real-world, demanding environments.

Comparative Analysis of Filters Accessories Manufacturers (Illustrative)

| Criteria | Manufacturer A (Premium) | Manufacturer B (Mid-Range) | Manufacturer C (Budget) |

|---|---|---|---|

| Certifications | ISO 9001, ASME U/UM, FDA, CE, NSF/ANSI 61 | ISO 9001, CE, some regional standards | Basic ISO 9001 |

| Material Traceability | Full MTRs for all wetted parts, complete lot control | Partial MTRs on request for critical components | Limited/None provided routinely |

| Customization | Extensive, dedicated engineering and design services | Standard modifications and limited custom configurations | Minimal or no customization options |

| Technical Support | Dedicated engineering team, 24/7 emergency support, on-site assistance | Standard business hours support, remote assistance | Basic customer service via email/phone |

| Warranty Period | 2-5 years standard, extended options available for critical systems | 1 year standard, no extended options | 6 months - 1 year, often limited scope |

| Lead Time (typical) | 4-8 weeks for custom designs, 1-2 weeks for stock items | 6-12 weeks for custom, 2-4 weeks for stock | 8-16 weeks, often with variability |

| Price Point | Higher initial investment, lowest long-term TCO | Moderate, balanced initial cost and TCO | Lower initial investment, potentially higher long-term TCO due to maintenance/replacement |

Figure 7: High-quality filter caps and seals, critical filtration system accessories, ensuring system integrity.

Tailored Excellence: Customization of Filters Accessories for Unique Needs

While off-the-shelf filtration system components meet the needs of many standard applications, complex industrial processes often require highly customized solutions to achieve peak performance and seamless integration. Partnering with a manufacturer capable of bespoke engineering offers significant advantages in terms of operational efficiency, system reliability, and specific compliance.

The Customization Process:

- Detailed Needs Assessment: In-depth consultation with client engineers and project managers to understand specific operational parameters, fluid characteristics (e.g., viscosity, corrosivity), space constraints, environmental conditions, and critical regulatory requirements. This initial phase defines the scope of customization.

- Design & Engineering: Utilizing advanced CAD/CAM software to develop custom designs, which can include specialized filter housings (e.g., jacketed for temperature control), complex manifold systems, unique connection types, or custom instrumentation mounting brackets. This phase often involves Finite Element Analysis (FEA) for stress testing and Computational Fluid Dynamics (CFD) for flow optimization.

- Material Specification: Expert selection of exotic alloys (e.g., Hastelloy, Monel, Titanium) or advanced engineered polymers (e.g., PEEK) to precisely handle extreme temperatures, pressures, or highly aggressive chemicals where standard materials are insufficient or unsafe.

- Prototyping & Testing: Creation of prototypes for rigorous functional testing and comprehensive validation under simulated operational conditions, ensuring the customized accessory meets all specified performance criteria and regulatory standards before full-scale production begins.

- Specialized Manufacturing & Quality Control: Production using specialized machinery, custom tooling, and dedicated processes, with intensified quality control checks meticulously tailored to the unique custom design and material specifications.

Benefits of Customized Filters Accessories:

- Optimized Performance: Components are precisely engineered and manufactured for your system's exact flow rate, pressure, temperature profile, and fluid chemistry, thereby minimizing pressure drop, maximizing filtration efficiency, and ensuring peak system output.

- Seamless Integration: Custom designs ensure a perfect physical and functional fit within existing infrastructure, reducing complex installation time, minimizing costly on-site modifications, and streamlining system upgrades.

- Extended Lifespan & Durability: The judicious selection of materials and manufacturing processes specifically tailored to combat the unique challenges of your operating environment leads to significantly longer component life and enhanced system resilience.

- Enhanced Safety & Compliance: Custom solutions can directly address specific safety concerns (e.g., pressure relief, ATEX certification for explosive atmospheres) or meet unique, stringent regulatory requirements which off-the-shelf products might not cover, ensuring operational safety and audit readiness.

- Cost Efficiency in the Long Run: While the initial investment for customized solutions might be higher, the gains in operational efficiency, reduced downtime, minimized maintenance, and significantly extended operational life translate into substantial long-term savings and a strong return on investment.

Real-World Application Cases and Client Success with Filters Accessories

Practical examples best illustrate the tangible impact of well-chosen filtration system components. Our extensive experience, spanning over two decades in the industrial filtration sector, has allowed us to partner with diverse industries globally, consistently delivering measurable improvements in their complex filtration processes.

Case Study 1: Enhanced Refinery Water Treatment and Efficiency

A major petrochemical refinery in the Middle East faced persistent operational challenges due to premature fouling of their cooling tower filters, primarily caused by high suspended solids in their intake water. The existing system’s basic pressure gauges provided insufficient data for proactive maintenance, leading to reactive filter changes and significant unplanned downtime. Our team conducted a thorough system audit and proposed an upgrade involving a suite of advanced filters accessories. This included smart differential pressure transmitters with integrated alarming capabilities, automated self-cleaning strainers, and intelligent, actuated backwash valves. This comprehensive upgrade allowed for precise real-time monitoring of filter loading, automated initiation of backwash cycles based on pre-set pressure differentials, and remote data logging.

Result: The client observed a dramatic 30% reduction in filter replacement frequency, a substantial 15% decrease in water consumption attributed to optimized backwashing, and a significant reduction in operational labor hours. The system now operates on a highly efficient predictive maintenance schedule, virtually eliminating unplanned downtime and enhancing overall refinery productivity and environmental compliance. The improved water quality also contributed to extended lifespan of other critical heat exchange equipment.

Case Study 2: Pharmaceutical Grade Water System Optimization for Sterility

A leading multinational pharmaceutical manufacturer in Europe required a critical upgrade to their Water for Injection (WFI) pre-treatment system, which demanded the highest levels of purity and sterility. Key concerns included preventing any possibility of bacterial ingress, ensuring absolute sterile connections, and simplifying validation processes. Our solution involved providing custom-fabricated SS316L sanitary filter housings designed with an ultra-smooth internal surface finish (filters accessories supplied were accompanied by full material traceability documentation (MTRs), FDA compliance statements (21 CFR Part 177), and extensive validation packages.

Client Feedback: "The precision-engineered filter housings and valves supplied by your team ensured unparalleled sterility and significantly eased our validation processes. Our WFI system now consistently meets the most stringent USP (United States Pharmacopeia) requirements, and the simplified Clean-in-Place (CIP) process saves us valuable production time and resources." This collaboration profoundly underscores the importance of precision engineering, meticulous material selection, and rigorous regulatory compliance in high-stakes, life-science environments.

Figure 8: Tailored filters accessories providing robust solutions for complex industrial challenges.

Building Trust: Quality Assurance, Delivery, and Customer Support for Filters Accessories

Trustworthiness is paramount in the B2B sector, especially when dealing with critical components like filters accessories that directly impact operational safety and efficiency. Our commitment extends beyond product delivery to comprehensive quality assurance, transparent processes, and unwavering customer support, forming the bedrock of long-term client relationships.

Rigorous Quality Assurance & Certifications:

All our filters accessories undergo stringent, multi-stage quality control procedures at every phase of manufacturing, from raw material inspection to final product testing. We operate under ISO 9001:2015 certified quality management systems, ensuring absolute consistency and excellence in design, manufacturing, and testing protocols. Critical components are subjected to 100% hydrostatic pressure testing to verify structural integrity against design pressure, material verification through Positive Material Identification (PMI) to confirm alloy composition, and detailed dimensional inspections using calibrated precision instruments. Where applicable, our products are meticulously designed and manufactured to comply with international standards such as ASME Boiler and Pressure Vessel Code, CE directives for European markets, and specific FDA regulations for food-grade or pharmaceutical contact applications. Our dedication to quality is not just a promise; it's a verifiable commitment backed by robust documentation, independent third-party accreditations, and an unwavering focus on engineering excellence.

Transparent and Reliable Delivery Cycle:

We fully understand the critical importance of timely delivery for maintaining operational continuity and meeting project deadlines. Our standard lead time for in-stock filtration components is typically 1-2 weeks, ensuring prompt availability for common requirements. For custom-engineered solutions, large-volume orders, or products requiring specialized materials, a detailed project timeline with clear milestones and regular updates is provided. This typical lead time ranges from 4-12 weeks, depending on the complexity of the design, specific material sourcing, and current production schedules. We maintain strong, strategic relationships with reliable domestic and international logistics partners to ensure efficient, secure, and trackable global delivery, with real-time tracking information available for our customers' convenience and peace of mind.

Comprehensive Warranty & Proactive Customer Support:

We stand firmly behind the durability, performance, and craftsmanship of our filters accessories with an industry-leading warranty of up to 5 years, depending on the specific product type and application. Our dedicated customer support team and highly experienced technical engineers are available to provide comprehensive assistance throughout the entire product lifecycle – from initial consultation, system design and specification, to installation support, operational troubleshooting, and responsive after-sales service. We pride ourselves on responsive communication, practical problem-solving, and a deep understanding of our clients' unique challenges, ensuring that our clients receive the expert assistance they need, precisely when they need it. Our service experience is built on over two decades of successful partnerships and an unwavering commitment to client satisfaction and operational excellence.

Figure 9: Emblem of our commitment to high-quality filters accessories and robust construction.

Frequently Asked Questions (FAQ) about Filters Accessories

Q1: How do I determine the correct material for my filtration accessories?

A1: Material selection is extremely critical and depends primarily on the fluid's chemical compatibility, operating temperature, and system pressure. For highly corrosive liquids or elevated temperatures, specialized stainless steel alloys (like SS316L or Duplex SS) or high-performance engineered polymers (such as PVDF) are strongly recommended. For general water treatment applications, PVC, PP, or SS304 may suffice. Always consult detailed material compatibility charts and, if uncertain, consult our experienced technical team to precisely match the material to your process conditions and avoid premature corrosion or degradation, ensuring long-term operational integrity.

Q2: What role do pressure gauges play in filtration systems?

A2: Pressure gauges, particularly differential pressure gauges, are vital filtration system components for accurately monitoring the pressure drop across the filter media. An increasing pressure drop indicates that the filter is becoming loaded with contaminants (fouling) and needs cleaning or replacement. This allows for highly proactive maintenance, preventing issues such as filter blinding, reduced flow rates, increased energy consumption by pumps, and potential catastrophic system damage. Integrating smart pressure transmitters can enable real-time monitoring and automated alerts.

Q3: Can filtration accessories improve the energy efficiency of my filtration system?

A3: Absolutely. Well-designed filtration accessories, such as optimized filter housings with minimal internal resistance, streamlined internal geometries, and high-efficiency valves, can significantly reduce the overall pressure drop across the entire system. A lower pressure drop means less energy is required by pumps to move the fluid through the system, leading to substantial energy savings and demonstrably lower operational costs over the long term. Investing in these efficient components is a key strategy for sustainable operations.

Q4: Are your filtration accessories compatible with existing filtration systems?

A4: Our filtration accessories are precisely designed and manufactured to meet common international standards for connection types (e.g., NPT, BSP, flange, sanitary clamp) and standard dimensions, ensuring broad compatibility with a wide range of existing filtration systems and piping infrastructures. For specific or legacy systems, or unique integration challenges, we also offer comprehensive custom design and fabrication services to ensure a perfect fit and seamless integration without requiring extensive and costly modifications to your existing setup. Our technical team can assist with compatibility assessments.

Q5: What is the typical lifespan of these accessories?

A5: The lifespan of filtration system components varies significantly depending on the material of construction, the specific operating conditions (e.g., extreme pressure, temperature fluctuations, fluid corrosivity, abrasion from suspended solids), and the adherence to recommended maintenance practices. High-quality filtration components made from SS316L, Duplex Stainless Steel, or robust engineered polymers can last 10-20 years or even longer under proper operating conditions and with regular care. Proactive maintenance, including proper cleaning, inspecting seals, and timely replacement of wear parts (like gaskets and O-rings), will significantly extend their service life and ensure consistent performance.

Figure 10: Robust design of filtration components ensuring long-term reliability.

Conclusion: Elevating Filtration Performance with Superior Filters Accessories

The comprehensive analysis of filters accessories underscores their undeniable importance in the efficacy, reliability, and economic viability of modern industrial filtration systems. Far from being mere add-ons, these components are foundational to ensuring optimal fluid purity, protecting valuable downstream equipment, and adhering to strict regulatory standards across diverse industries. From precision-engineered housings and robust valves to intelligent sensors and specialized fittings, each accessory plays a critical and interconnected role in the overall system's performance, operational lifespan, and safety profile.

By strategically investing in high-quality filtration components from reputable manufacturers that prioritize advanced manufacturing processes, rigorous testing, and comprehensive technical support, industries can unlock significant and tangible advantages. These benefits include enhanced energy efficiency through optimized flow dynamics, superior corrosion resistance for longevity in harsh environments, extended equipment lifespan, substantial reductions in maintenance costs, and minimized unplanned downtime. Whether it's for demanding petrochemical processes, critical pharmaceutical applications, or large-scale municipal water treatment, the right selection and meticulous integration of filtration accessories, often in conjunction with synergistic solutions like an ro booster pump kit and an ro consumables kit, translate directly into improved operational resilience, increased productivity, and a stronger financial bottom line. Choosing a partner with proven expertise, a deep understanding of your industry, and an unwavering commitment to quality ensures that your filtration infrastructure is not just functional, but truly optimized for present and future challenges.

References

- Mulder, M. (1996). Basic Principles of Membrane Technology (2nd ed.). Kluwer Academic Publishers.

- Crittenden, J. C., Trussell, R. R., Hand, D. W., Howe, K. J., & Tchobanoglous, G. (2012). Water Treatment: Principles and Design (3rd ed.). John Wiley & Sons.

- Cheremisinoff, N. P. (2002). Handbook of Water and Wastewater Treatment Technologies. Butterworth-Heinemann.

- Perry, R. H., & Green, D. W. (Eds.). (2008). Perry's Chemical Engineers' Handbook (8th ed.). McGraw-Hill Education.

- Wang, L. K., Chen, J. P., Hung, Y. T., & Shammas, N. K. (Eds.). (2005). Membrane and Desalination Technologies. Humana Press.

Post time: Aug-21-2025