Inside the world of Cabin Air Filtration: what’s really under the hood

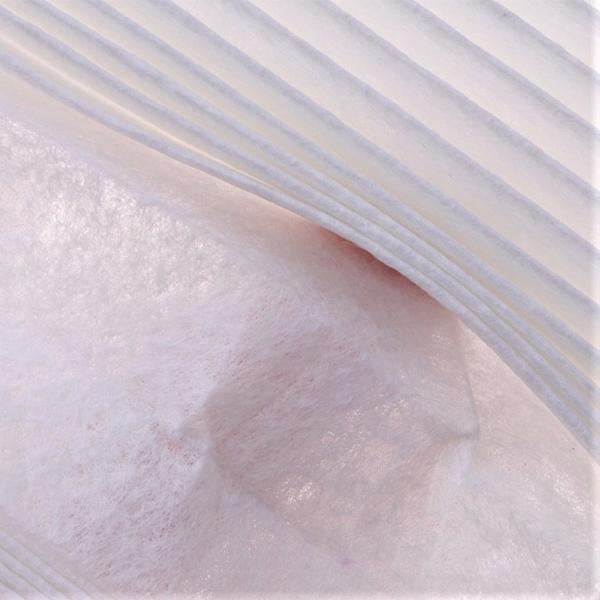

I’ve toured more filter lines than I can count, and—honestly—the difference between a great cabin filter and a merely okay one usually comes down to media design. That’s why I spent time with the team behind Cabin Air Filter Media in Hebei. Their pitch sounds simple: uniform thickness, long life, big burst resistance, pleats that don’t spring back, no smell and absorbs odors. The interesting part is how they actually make it happen.

What’s trending (and why it matters)

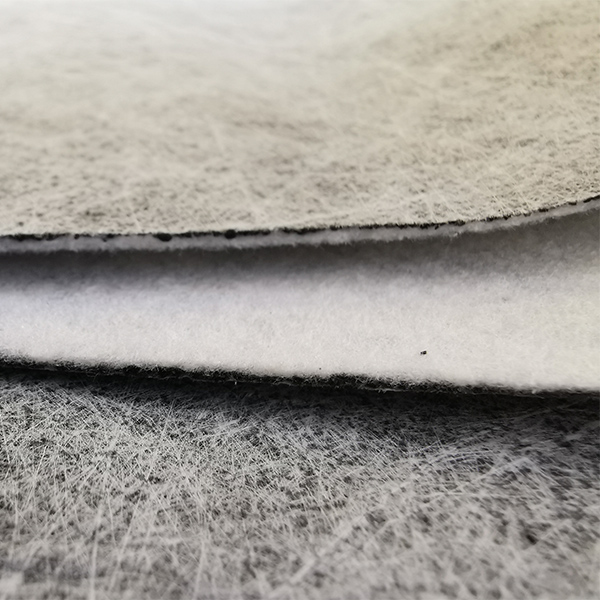

Electrification shifted the focus from engine intake to people intake—your lungs. OEMs now spec higher ePM1 capture (PM1 is the tiny stuff) and more VOC control for urban traffic. Fleet managers tell me riders increasingly complain about odor and haze; surprisingly, they’ll notice the cabin air before ride comfort. This is where Cabin Air Filter Media with an optional activated-carbon layer earns its keep.

How it’s made (short version)

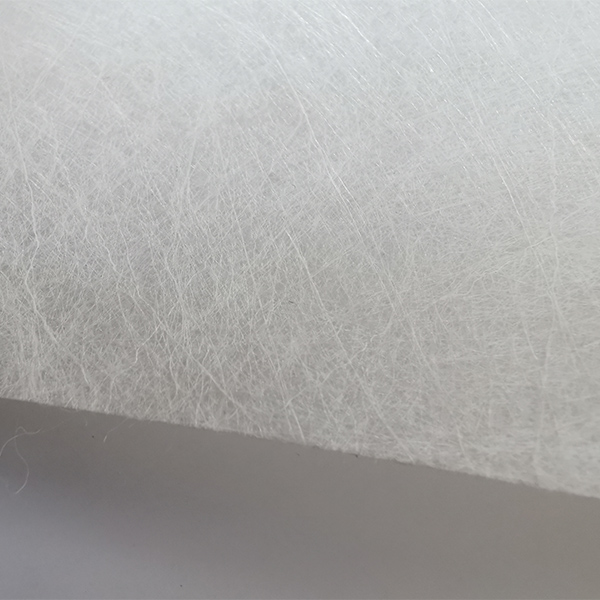

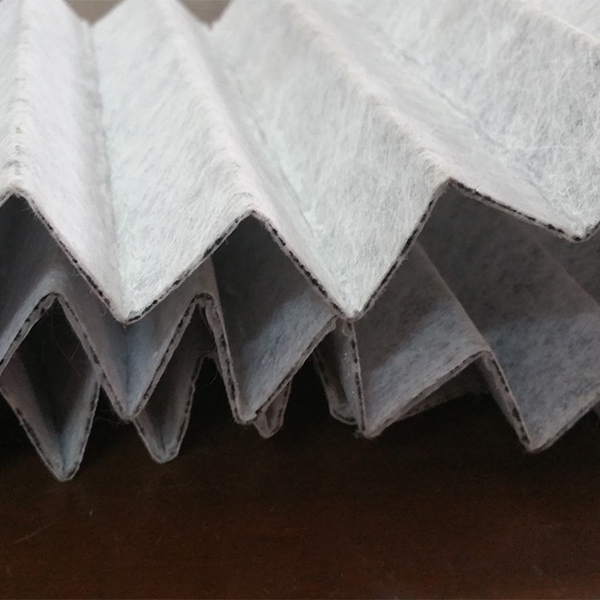

Materials: PET/PP synthetic fibers (spunbond + meltblown stack), electrostatic treatment, and an optional powdered activated carbon (PAC) layer with low-odor binder. Methods: thermal calendaring, multilayer lamination, edge sealing, then pleat formation (mini-pleat or deep-pleat). QC gates at basis weight, thickness, Gurley stiffness, and burst strength. To be honest, the uniformity check is where many lines slip—this one felt tight.

| Parameter | Typical spec (≈) | Notes |

|---|---|---|

| Basis weight | 120–180 g/m² | Varies by efficiency class |

| Thickness | 0.6–1.2 mm | Uniform thickness for stable pleating |

| ISO 11155-1 efficiency | ePM1 60–85% | Real-world use may vary |

| Initial ΔP @ 0.053 m³/s | ≈ 45–80 Pa | Depends on media grade |

| Dust holding (ASH loading) | ≈ 60–120 g/m² | To terminal ΔP ≈ 200 Pa |

| Burst resistance | > 350 kPa | Large burst resistance |

| Odor/VOC layer | PAC 80–120 g/m² | No smell, absorbs odors |

Testing, standards, and service life

Particulate efficiency and dust loading are tested per ISO 11155-1; gas-phase reduction per ISO 11155-2. Some customers also benchmark to ISO 16890 ePM classes for reference. Typical service life is 12,000–20,000 km (or 6–12 months) depending on AQI and recirculation rates. Fleet trials show pressure drop stays stable until ≈70% of stated life, then rises faster—pretty normal behavior.

Certifications available: material RoHS/REACH compliance statements; factory-level ISO 9001/14001; and batch CoA with flat-sheet data. Many customers say the “no smell” claim holds up even in hot, humid cabins—always a good sign the binder is clean.

Who should use it (and how)

- Automotive Tier-1/Tier-2 converting into panel or honeycomb cabin filters

- Aftermarket brands targeting PM2.5 and odor control

- Ride-hailing fleets in high-AQI cities; bus and light truck HVAC retrofits

| Vendor | Lead time | MOQ | ePM1 eff. | Carbon layer | Notes |

|---|---|---|---|---|---|

| Anya (Hebei) | 2–4 weeks | ≈ 500 m² | 60–85% | PAC or blend | Custom widths, steady QC |

| Vendor A (Generic) | 4–6 weeks | ≈ 1,000 m² | 50–70% | Optional | Lower cost, variable uniformity |

| Vendor B (Premium EU) | 3–5 weeks | ≈ 300 m² | 70–90% | PAC/chemisorptive | Higher price, strong data pack |

Customization and logistics

Cabin Air Filter Media can be supplied in rolls or sheets, widths 100–1,200 mm, with or without carbon, and tailored stiffness for different pleat pitches. OEM color marking and lot traceability are available. Origin: No.580 Gongnong Road, Shijiazhuang City 050000, Hebei, P.R. China. For converters, slitting tolerances around ±0.5 mm help reduce pleat wander—nice touch.

Field notes (quick cases)

- Taxi fleet, Southeast Asia: switch to Cabin Air Filter Media + carbon cut cabin VOCs ≈30–40% (toluene/benzene proxies) and extended change interval from 10k to 16k km.

- European aftermarket brand: mini-pleat version improved initial ΔP ≈15% vs. prior media, same ePM1 class—drivers reported “quieter blower at speed.”

If you need a steady, low-odor media with solid pleatability, this one is worth a test lot. As always, validate against your frame geometry and local dust profile.

Authoritative citations

- ISO 11155-1: Road vehicles—Air filters for passenger compartments—Part 1: Test for particulate filtration.

- ISO 11155-2: Road vehicles—Air filters for passenger compartments—Part 2: Test for gaseous filtration.

- ISO 16890 series: Air filters for general ventilation—Particulate matter efficiency (ePM) rating framework.

- GB/T 32085.1—2015: Chinese standard equivalent to ISO 11155-1.

Post time: Nov-06-2025