Air Filter Paper Material is a key solution in the manufacturing industry, specifically within Material manufacturing industry and Manufacturing of filter materials. This article explores how ANYA FILTER MEDIA CO., LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Air Filter Paper Material Overview

- Benefits & Use Cases of Air Filter Paper Material in Manufacturing of filter materials

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Air Filter Paper Material from ANYA FILTER MEDIA CO., LTD

Air Filter Paper Material Overview

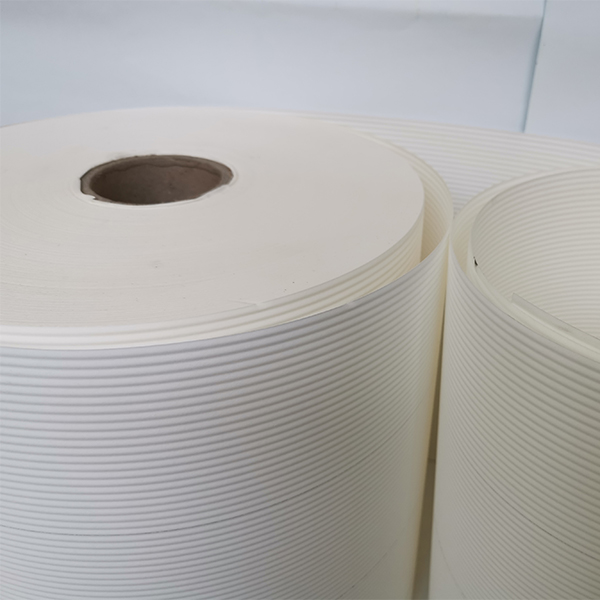

Air Filter Paper Material is an engineered, porous media designed to capture airborne particulates while maintaining low resistance to airflow. In the Material manufacturing industry—especially the Manufacturing of filter materials—it serves as the core substrate used to produce pleated panels, cartridges, bags, and high-efficiency elements. Typical constructions include cellulose, synthetic fibers, and glass microfiber matrices, often resin-impregnated for stiffness, pleatability, and moisture resistance. B2B decision makers prioritize consistent basis weight, pore-size distribution, and mechanical integrity to ensure reliable converting performance and stable field operation.

- Core specs commonly evaluated include basis weight (e.g., 60–200 g/m²), thickness, porosity, initial efficiency (from coarse dust capture to HEPA-grade), pressure drop at rated face velocity, wet/dry burst strength, and resin content. Converters also assess pleat recovery and edge stability during high-speed operations.

- For cleanroom and critical HVAC applications, materials aligned with ISO 16890 or EN 1822 test methodologies are important. For general HVAC, ASHRAE 52.2/MERV performance and dust-holding capacity guide media selection.

- ANYA FILTER MEDIA CO., LTD manufactures dependable Air Filter Paper Material with tight tolerances and consistent roll-to-roll quality, supporting filter makers with scalable supply and application guidance. Explore the range here: ANYA Air Filter Paper.

Benefits & Use Cases of Air Filter Paper Material in Manufacturing of filter materials

In the Manufacturing of filter materials, Air Filter Paper Material becomes the functional heart of end products. It is widely used in HVAC pleated filters for commercial buildings, industrial dust collection prefilters, automotive cabin systems as AC filter paper, and cleanroom or medical devices where HEPA performance is needed—often supplied as a HEPA filter paper roll for efficient converting. Across these segments, converters seek media that balances particle capture efficiency with minimized pressure drop to reduce fan energy and extend service intervals.

- Competitive advantages include uniform pore structure for predictable efficiency, resin impregnation for pleat stability, optional hydrophobicity for humid environments, and stable caliper for precise pleat geometry. Consistency reduces scrap, setup time, and quality variation on the line.

- ANYA FILTER MEDIA CO., LTD supports multiple formats—master rolls, custom slit widths, and converter-ready specifications—streamlining downstream processes such as die-cutting, pleating, and thermal/adhesive bonding. This helps OEMs and private-label producers optimize throughput and product performance.

- From HVAC panels to compact cartridges and high-efficiency HEPA units, Air Filter Paper Material from ANYA is engineered to integrate smoothly with common pleat pack designs and frame systems, reducing variability across SKUs.

Cost, Maintenance & User Experience

Total cost of ownership in filtration is driven by media price, energy consumption, lifetime, and changeout labor. Well-engineered Air Filter Paper Material can lower fan energy via reduced pressure drop and increase dust-holding capacity for longer service life. For converters, consistent roll build, tight grammage tolerance, and clean edges reduce setup time and downtime, improving yield and overall equipment effectiveness (OEE). When scaled across multiple lines, these factors translate into measurable ROI for B2B buyers.

- A practical ROI lens: Energy savings + extended change intervals + waste reduction − incremental media cost. Many facilities prioritize media that stabilizes ΔP over its service life to keep HVAC systems within optimal efficiency bands.

- Feedback commonly cited by Material manufacturing industry stakeholders includes smoother pleating at high speeds, fewer splice-related stoppages, and predictable efficiency curves that simplify certification and QA. End users report improved indoor air quality and more consistent maintenance planning.

- ANYA FILTER MEDIA CO., LTD focuses on converter-friendly specifications and dependable supply continuity—key requirements for planners managing multi-site operations and tight delivery windows.

Sustainability & Market Trends in manufacturing

Sustainability is reshaping air filtration. Standards like ISO 16890 (global HVAC classification) and EN 1822 (HEPA/ULPA) align product performance with real-world particle size distributions, while building frameworks (LEED, WELL) motivate higher IAQ and lower energy use. In parallel, many buyers seek media options with reduced formaldehyde content, water-based resin systems, or recycled fibers—without compromising filtration efficiency or structural integrity.

- Market growth is propelled by tighter indoor air requirements, electrification trends (thermal management), and heightened attention to occupant health. Converters that can document performance and material traceability gain an edge with institutional and industrial buyers.

- ANYA FILTER MEDIA CO., LTD positions its Air Filter Paper Material portfolio to support compliance with prevailing test standards and to align with customers’ sustainability targets, including efficient media architectures that reduce energy consumption across the filter’s service life. The company continually evaluates materials and processes that help partners deliver greener, higher-performing filters to market.

Conclusion on Air Filter Paper Material from ANYA FILTER MEDIA CO., LTD

For B2B decision makers in the Manufacturing of filter materials, Air Filter Paper Material remains a pivotal lever for product performance, manufacturing efficiency, and lifecycle cost. By combining stable pore structure, low pressure drop, and converter-ready formats—including AC filter paper and HEPA filter paper roll options—ANYA FILTER MEDIA CO., LTD provides reliable substrates for HVAC, automotive, and cleanroom applications. Partner with a manufacturer focused on repeatable quality and practical support.

- ANYA FILTER MEDIA CO., LTD is a trusted partner for consistent performance and supply continuity.

- Contact us: email: sales@anyafiltermedia.com

- Visit our website: https://www.anyafiltermedia.com

Post time: Nov-10-2025