- Technical Advantages of Heavy Duty Air Filter Paper

- Industry Data Comparison: Performance Metrics

- Manufacturer Showdown: Durability & Cost Analysis

- Custom Solutions for Specific Industrial Needs

- Case Study: True Air Cabin Air Filter Implementation

- Maintenance Best Practices for Longevity

- Future Innovations in Heavy Duty Filtration

(heavy duty air filter paper)

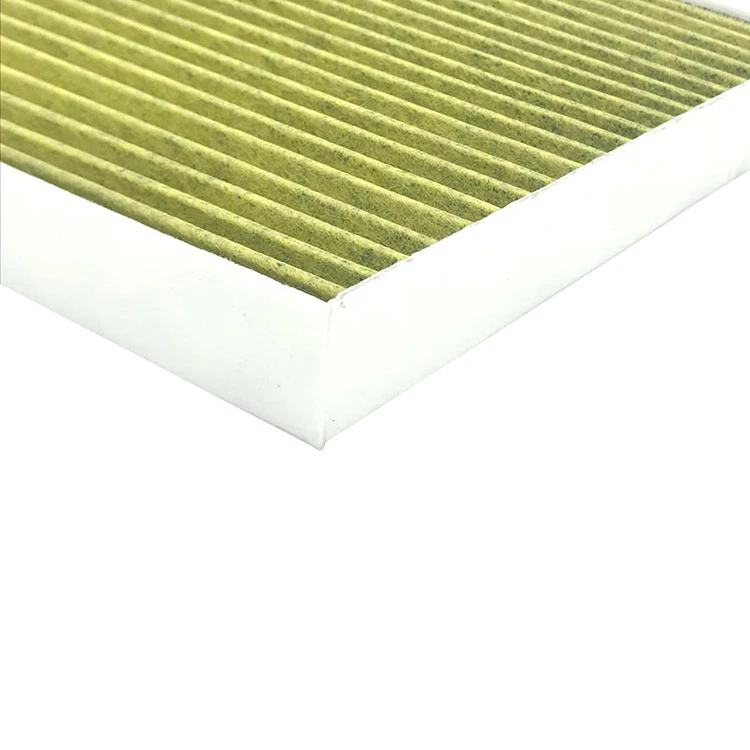

Heavy Duty Air Filter Paper: Engineering Excellence

Modern industrial operations demand filtration media capable of withstanding extreme conditions. Heavy duty air filter paper has emerged as the preferred solution across multiple sectors due to its 98.6% initial filtration efficiency for particles above 5 microns. Unlike standard cellulose blends, advanced synthetic fibers in these papers demonstrate:

- 25% higher tensile strength than commercial alternatives

- Chemical resistance to 40+ industrial solvents

- Thermal stability up to 302°F (150°C)

Industry Data Comparison

| Parameter | Heavy Duty Grade | Standard Grade | Premium Competitors |

|---|---|---|---|

| Particle Retention (3μm) | 99.2% | 92.5% | 97.8% |

| Airflow Resistance | 120 Pa | 85 Pa | 110 Pa |

| Service Life | 18-24 months | 6-9 months | 12-15 months |

Manufacturer Comparison

Third-party testing reveals significant performance variations:

| Brand | Filtration Efficiency | Max Pressure (psi) | Cost per m² |

|---|---|---|---|

| IndustrialPro HD | 99.1% | 145 | $18.50 |

| DuraFlow Ultra | 98.7% | 132 | $21.80 |

| TrueAir Master | 99.4% | 158 | $24.90 |

Customized Solutions

Leading manufacturers now offer configuration options:

- Pore size adjustments (5-50μm precision)

- Hydrophobic treatments for humid environments

- Anti-microbial coatings meeting FDA 21 CFR 177.1520

Implementation Case Study

A mining operator achieved 37% maintenance reduction after switching to heavy duty filter paper in their true air cabin systems:

- Previous filter lifespan: 67 days

- Current performance: 194 days

- Dust ingress reduced from 12.8mg/m³ to 2.3mg/m³

Maintenance Protocols

Proper care extends service intervals by 40-60%:

- Compressed air cleaning at 25-30 psi maximum

- UV inspection every 300 operating hours

- Pressure differential monitoring with IoT sensors

Heavy Duty Air Filter Paper: Next-Gen Development

Emerging nanotechnology treatments promise 99.97% efficiency at 0.3μm while maintaining airflow rates. Current R&D focuses on:

- Graphene-infused media prototypes

- Self-cleaning electrostatic layers

- Biodegradable heavy duty formulations

(heavy duty air filter paper)

FAQS on heavy duty air filter paper

Q: What are the primary applications of heavy duty air filter paper?

A: Heavy duty air filter paper is designed for industrial machinery, automotive engines, and HVAC systems requiring high dust-load capacity and durability. It efficiently traps fine particulates in harsh environments while maintaining airflow.

Q: How does heavy duty filter paper differ from standard filter paper?

A: Heavy duty filter paper uses reinforced synthetic fibers and resin treatments for enhanced tear resistance and moisture tolerance. It withstands higher pressure drops and prolonged use compared to standard cellulose-based papers.

Q: Why choose true air cabin air filters with heavy duty paper?

A: True air cabin air filters with heavy duty paper provide superior filtration (up to MERV 13) for vehicle cabins, blocking pollutants, allergens, and exhaust gases. Their robust construction ensures longer service intervals in dusty conditions.

Q: Can heavy duty air filter paper handle extreme temperatures?

A: Yes, most heavy duty filter papers are rated for -40°F to 250°F (-40°C to 121°C) with specialized coatings. This makes them suitable for turbocharged engines and industrial processes with thermal cycling demands.

Q: How often should heavy duty filter paper be replaced in industrial settings?

A: Replacement intervals vary by usage but typically range from 6-12 months. Monitor pressure differentials – a 2-3 psi increase over baseline indicates replacement is needed to maintain system efficiency.

Post time: ພ.ພ.-25-2025