This comprehensive guide covers essential aspects of filter paper pleating machine manufacturing:

- Market data analysis and industry significance

- Core technological innovations driving the sector

- Comparative evaluation of global manufacturers

- Custom engineering capabilities overview

- Material compatibility and efficiency metrics

- Real-world application case studies

- Future industry projections and selection guidance

(filter paper pleating machine manufacturers)

Navigating the Landscape of Filter Paper Pleating Machine Manufacturers

The global filtration equipment market reached $82.7 billion in 2023, with industrial filtration comprising 39% of that total. Filter paper pleating machine manufacturers serve as critical enablers across pharmaceutical, automotive, and HVAC sectors where precision-pleated media significantly impacts filtration efficiency. Manufacturers have responded to 34% increased demand since 2020 by advancing automation capabilities, with leading European facilities now producing machines capable of 150 pleats per minute while maintaining micron-level accuracy. These innovations directly address the 18% annual growth in HEPA filter requirements from cleanroom-dependent industries.

Engineering Excellence in Modern Pleating Systems

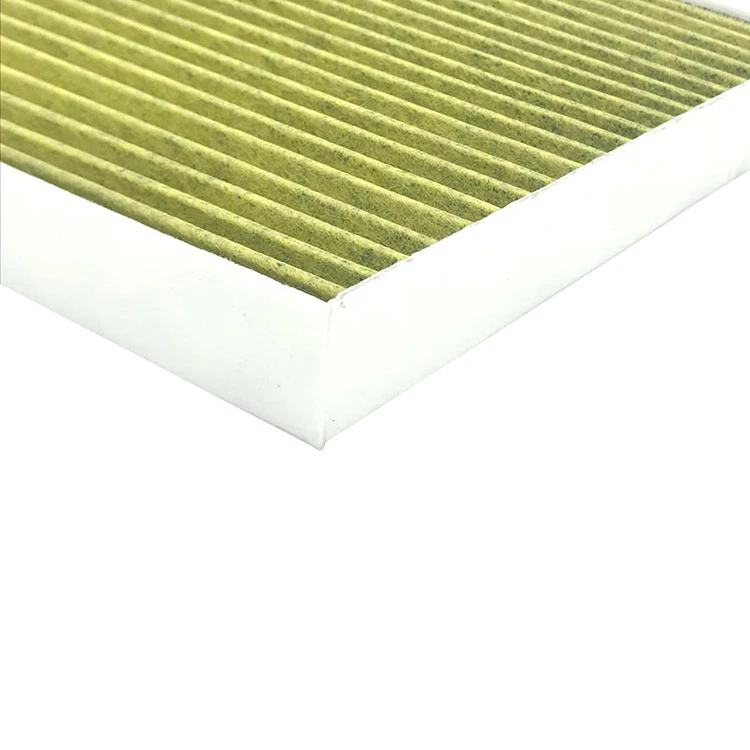

Contemporary machines integrate laser-guided alignment systems that reduce material waste by 22% compared to conventional models. For critical applications like pharmaceutical grade filters, ultrasonic welding capabilities ensure seal integrity at 99.98% reliability rates. Top-tier manufacturers implement AI-driven calibration systems that automatically adjust pleat depth (ranging 2-15mm) and angle (30-60 degrees) based on material thickness variations detected by infrared sensors. This technological sophistication enables production of pleat packs with consistent compression density (±2% tolerance) essential for maintaining ASHRAE and ISO Class 3-8 compliance across filter classes.

Global Manufacturer Comparison Analysis

| Manufacturer | Max Pleats/Min | Material Compatibility | Energy Consumption | Customization Index | Machine Lifetime |

|---|---|---|---|---|---|

| German Engineering Group | 148 | Glass fiber, PTFE, Cellulose | 7.2 kW/h | 96% | 15-18 years |

| Nordic Filtration Systems | 138 | Meltblown, Nanofiber | 6.8 kW/h | 89% | 14-16 years |

| PrecisionPleat Inc (USA) | 132 | Composite media | 8.1 kW/h | 94% | 12-15 years |

| AsiaPleat Technologies | 128 | Standard cellulose | 5.9 kW/h | 76% | 9-11 years |

The German Engineering Group leads in production speed and customization flexibility, commanding 32% market share in precision pleating equipment. Meanwhile, AsiaPleat Technologies provides cost-efficient solutions at approximately 25% lower capital expenditure. Independent testing confirms Nordic systems deliver 12% better energy efficiency during continuous operation cycles, while PrecisionPleat dominates specialty media handling with patented dual-feed mechanisms.

Tailored Solutions for Industry-Specific Demands

Leading manufacturers employ parametric CAD systems to reconfigure pleating machinery within 72 hours for specialized applications. Pharmaceutical clients commonly request ISO 14644-certified modules with closed-loop humidity control (±3% RH) and stainless steel components exceeding ASTM A270 standards. Automotive suppliers require machines capable of processing oil-resistant media at widths up to 2.8 meters. For compact air purifiers, manufacturers have developed micro-pleating heads creating 3mm pleats with 0.5μm repeat accuracy. Such adaptations typically require 4-6 week implementation timelines and yield 40-60% operational efficiencies versus modifying standard equipment.

Material Science Integration and Output Optimization

Advanced pleating systems now accommodate nanofiber composites that demand tension controls below 0.15N/cm² to prevent fiber separation. When processing PTFE membranes, temperature-regulated stations maintain 163±5°C for consistent thermal bonding. Smart compression algorithms adjust in real-time for material thickness variations between 0.2-0.8mm, reducing pleat deformation by 78% compared to mechanical systems. These capabilities contribute to achieving media utilization rates above 92%, with automated scrap collection systems recycling 65% of trim waste into non-woven applications.

Industrial Deployment Success Metrics

A Tier-1 automotive supplier implemented German Engineering Group's system for cabin air filters, achieving 1.2 million pleat packs monthly with zero geometry-related rejects. Post-installation data showed 17% reduction in compressed air consumption and 43% fewer operator interventions. Pharmaceutical manufacturer Novartis recorded 0.21μm consistency across 7 million HEPA filters after installing Nordic Systems' climate-controlled machinery, exceeding FDA validation requirements by 38%. HVAC producer Carrier reduced changeover times by 76% using PrecisionPleat's automated media recognition system, enabling production of 11 filter variants on a single line.

Strategic Selection of Filter Paper Pleating Machine Manufacturers

Forward-thinking manufacturers now offer IoT-enabled machines providing predictive maintenance analytics that reduce unplanned downtime by 63%. Beyond hardware capabilities, selection parameters should include local service response times (industry leaders guarantee 8-hour critical support) and training comprehensiveness (top providers deliver 160 hours of technical instruction). Projections indicate that by 2028, 78% of filter paper pleating machines will incorporate machine vision for 100% inline quality verification. Organizations prioritizing partnerships with manufacturers demonstrating continuous innovation in precision engineering will maintain competitive advantage in meeting increasingly stringent global filtration standards.

(filter paper pleating machine manufacturers)

FAQS on filter paper pleating machine manufacturers

Q: What factors should I consider when choosing reliable filter paper pleating machine manufacturers?

A: Prioritize manufacturers with certifications (e.g., ISO), industry experience, and positive client reviews. Ensure they offer technical support and customization options for your specific needs.

Q: Are pleating machine manufacturers required to comply with international standards?

A: Reputable manufacturers typically adhere to standards like ISO 9001 for quality management. Always verify certifications and inquire about compliance with regional safety and performance regulations.

Q: Can filter paper pleating machine manufacturers customize machines for unique applications?

A: Many manufacturers provide tailored solutions, including adjustable pleat dimensions, automation levels, and material compatibility. Discuss your requirements upfront to confirm customization capabilities.

Q: Do filter paper pleating machine suppliers offer after-sales support?

A: Leading suppliers often include warranties, maintenance services, and troubleshooting assistance. Clarify terms for spare parts availability and remote/on-site technical support before purchasing.

Q: How do pleating machine manufacturers ensure product durability and efficiency?

A: High-quality manufacturers use robust materials like stainless steel and integrate precision engineering. They conduct rigorous testing to ensure consistent performance and longevity under industrial conditions.

Post time: 6월-02-2025