Composite Fiberglass Lim Media

Cov xov xwm lim dej no yog ua los ntawm cov iav microfiber ua cov txheej lim dej, laminated nrog hluavtaws fiber ntau raws li kev tiv thaiv thiab kev txhawb nqa txheej ntawm ib sab lossis ob sab.

Khoom feature:

Siab plua plav tuav peev xwm

Tsawg cua tsis kam

High filtration efficiency

Zoo pleating durability

Cov khoom siv tshuaj ruaj khov

Daim ntawv thov: Ntawm cov ntxaij lim dej ntawm cov tshuab ua haujlwm hnyav, roj-dej cais, roj roj (diesel / roj av), Aircraft roj, Hydraulic roj, roj lubrication, compressed cua, Pharmacy, Tshuaj, Pre-filtration, thiab lwm yam.

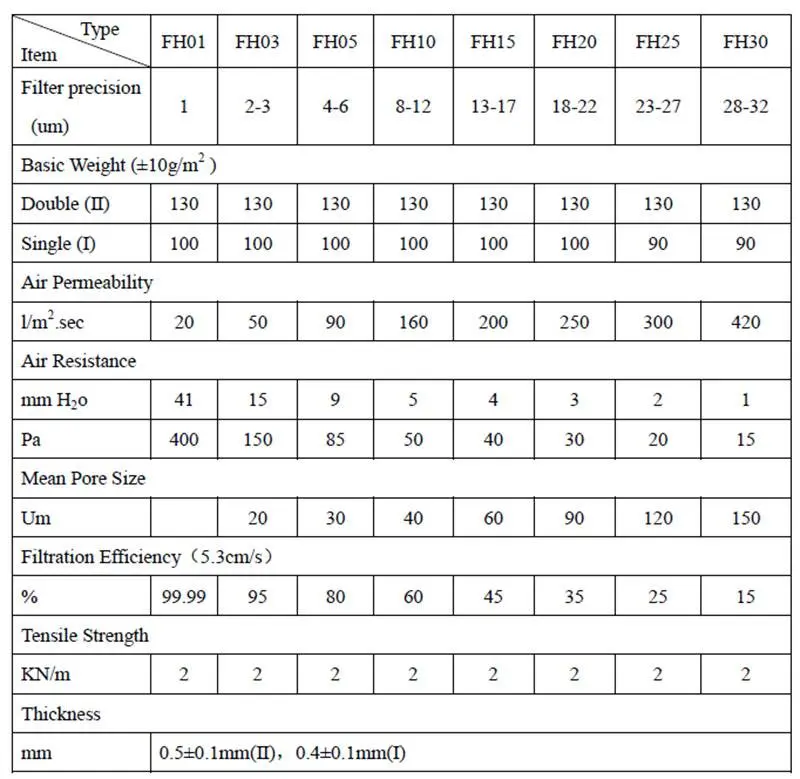

Khoom Specification:

Nco tseg: II yog cov cai ntawm ob sab sib xyaw fiberglass lim ntawv. Kuv yog cov cai ntawm ib sab sib xyaw fiberglass lim ntawv.

High-Efficiency Particulate Removal with Composite Fiberglass Filter Media

Composite fiberglass filter media delivers superior particulate removal by combining glass fibers with advanced synthetic materials, creating a high-performance filtration solution. The tightly interwoven fibers form a dense yet porous structure capable of capturing sub-micron particles, including dust, pollen, and even bacteria, with exceptional efficiency. Unlike standard fiberglass filters, composite media often incorporates additional layers or coatings to enhance particle retention while maintaining low airflow resistance. This makes it ideal for applications requiring both high filtration efficiency and energy efficiency, such as hospitals, laboratories, and industrial cleanrooms. The composite design also improves durability, allowing the filter to withstand harsh conditions without compromising performance. By balancing high-efficiency particle capture with optimized airflow, this media ensures cleaner air and longer filter life.

Use of Composite Fiberglass Filter Media in Cleanrooms and Controlled Environments

In cleanrooms and controlled environments, composite fiberglass filter media is critical for maintaining ultra-low particulate counts. Its multi-layered construction provides consistent filtration performance, meeting stringent ISO and HEPA standards for air purity. The media’s ability to trap microscopic contaminants ensures compliance with pharmaceutical, semiconductor, and biotechnology industry requirements. Unlike traditional filters, composite fiberglass resists moisture and chemical exposure, preventing microbial growth and material degradation in sterile settings. Additionally, its low particulate shedding prevents secondary contamination, a key concern in sensitive manufacturing processes. By offering reliable, high-efficiency filtration, composite fiberglass media helps sustain controlled environments where even minor airborne particles can compromise product quality or research integrity.

Applications of Composite Fiberglass Filter Media

Composite fiberglass filter media is widely used across industries due to its versatility and high performance. In HVAC systems, it enhances indoor air quality by capturing fine particulates while maintaining energy-efficient airflow. Automotive applications include cabin air filters, where the media traps pollutants and allergens, and engine intake systems, where it protects against abrasive dust. Paint booths rely on composite fiberglass filters to capture overspray, ensuring a flawless finish and preventing contamination of exhaust systems. The media’s chemical resistance and thermal stability make it suitable for harsh environments, while its customizable density allows for tailored filtration solutions. Whether improving air quality, protecting machinery, or ensuring product consistency, composite fiberglass media delivers reliable performance across diverse applications.