A Practical Insider’s Guide to Paint Stop Filter Media for Modern Spray Booths

If you spray anything from car bumpers to metal cabinets, you’ve probably wrestled with overspray. That’s exactly where paint stop filter media earns its keep. I’ve visited more booths than I can count, and—honestly—most performance issues trace back to neglected prefilters or bargain matting that compacts too fast.

What it is (and why shops still swear by it)

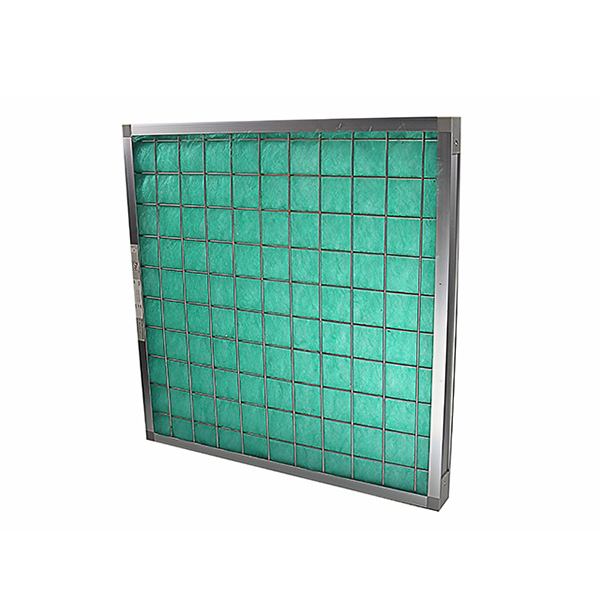

paint stop filter media is a progressively structured fiberglass mat designed to trap wet overspray before it coats fans, ducts, and heat exchangers. It’s low-resistance, tolerant to heat, and, in fact, surprisingly forgiving in mixed-production booths using high-solids or waterborne coatings.

Industry trends I’m seeing

- Shift to waterborne and high-solids paints, creating stickier overspray.

- More attention on energy use; low ΔP media saves blower power.

- Cleaner downstream filtration for compliance and finish quality.

Key specifications

Short Description: Low initial resistance, high separation efficiency, high temperature resistance. Origin: No.580 Gongnong Road, Shijiazhuang City 050000, Hebei, P.R. China.

| Base media | Progressive fiberglass mat, resin-bonded |

| Thickness | ≈ 50 mm (2 in), other options on request |

| Initial resistance | ≈ 18–30 Pa at 0.5 m/s face velocity (real-world may vary) |

| Overspray arrestance | ≈ 93–97% for >10 µm droplets (per legacy paint-arrestor methods) |

| Paint holding capacity | ≈ 2.5–4.0 kg/m² depending on coating |

| Temperature resistance | Up to ≈ 170°C continuous |

| Fire rating | DIN 53438 (F1/F2 classes, as specified) |

| Common roll sizes | 1×20 m, 1×10 m; custom widths |

How it’s made and tested

Materials: long-staple fiberglass, progressively layered from coarse (air entry) to fine (air exit) with resin points to prevent collapse. Methods: thermal forming, density grading, then trim to rolls or pads. QA checks include basis weight, thickness, ΔP at set velocity, and burn test per DIN 53438. For downstream HVAC filters, many shops reference ISO 16890 and ASHRAE 52.2 classifications—even though those apply to air filters rather than paint arrestors specifically.

Where it’s used

- Automotive refinish and OEM lines

- Furniture and joinery shops

- General metal finishing, rail, marine touch-up

- Aerospace components and MRO hangars

Service life: replace paint stop filter media when pressure drop doubles, face velocity falls, or visual loading reaches ≈ 75% of depth. In busy booths, that’s 2–6 weeks; light-duty shops often get 2–3 months. Always check local compliance rules.

Vendor snapshot (what buyers compare)

| Vendor | Origin | Arrestance ≈ | Roll options | Certs/Tests | Lead time |

|---|---|---|---|---|---|

| Anya Filter Media | China | 93–97% | 1×10/20 m; customs | DIN 53438; factory QC | Fast (stock-dependent) |

| Generic Importer A | Mixed | 90–95% | Limited widths | Basic burn test | Variable |

| Premium EU Brand | EU | 95–98% | Wide catalog | DIN/ISO docs | Stocked |

Values are indicative; real-world use may vary by paint type, velocity, and maintenance.

Customization and install tips

- Cut pads to booth floor grid; seal edges to prevent bypass.

- Choose density to match paint load; higher basis weight for heavy build coats.

- Pair with downstream HVAC filters rated by ISO 16890 for airborne particulates.

Real-world notes

A Midwest body shop told me their paint stop filter media swap reduced fan amp draw by “about 12%,” measured at the VFD—small change, real savings. A furniture plant reported fewer dust nibs after switching to progressive matting; they also liked the clean peel-off when saturated.

Compliance touchpoints

For spray finishing areas, check OSHA 1910.94 and your local fire code. Aerospace and industrial painters sometimes reference EPA NESHAP requirements and method-specific capture efficiencies. Downstream air cleanliness targets may follow ISO 14644 in controlled zones, though most body shops don’t go that far.

Citations

- ISO 16890: Air filters for general ventilation (overview): https://www.iso.org/standard/53355.html

- ASHRAE 52.2: Method of testing general ventilation air-cleaning devices: https://www.ashrae.org

- DIN 53438: Testing of combustibility of air filter media: https://www.din.de

- OSHA 1910.94: Ventilation for spray finishing: https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.94

- EPA NESHAP (surface coating, general resources): https://www.epa.gov/stationary-sources-air-pollution/national-emission-standards-hazardous-air-pollutants-neshap

Post time: Oct-20-2025