High Filtration Efficiency Flame- Retardant Filter Paper is a key solution in the manufacturing industry, specifically within Paper and paper products industry and Manufacturing of special industrial paper. This article explores how ANYA FILTER MEDIA CO., LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- High Filtration Efficiency Flame- Retardant Filter Paper Overview

- Benefits & Use Cases of High Filtration Efficiency Flame- Retardant Filter Paper in Manufacturing of special industrial paper

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on High Filtration Efficiency Flame- Retardant Filter Paper from ANYA FILTER MEDIA CO., LTD

High Filtration Efficiency Flame- Retardant Filter Paper Overview

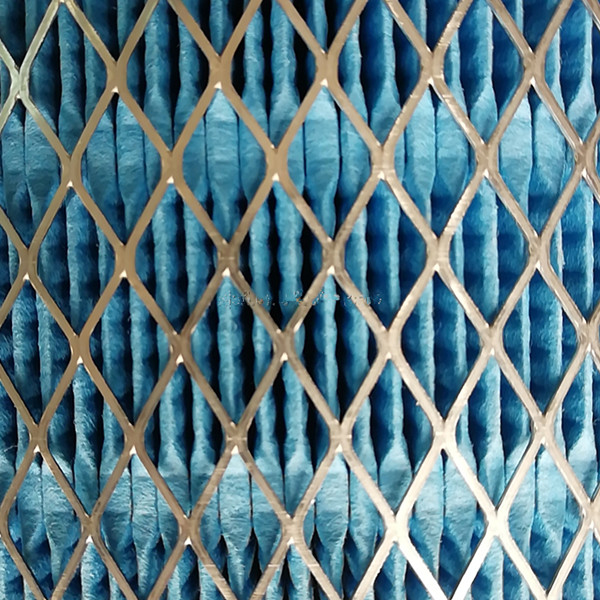

For B2B decision makers in the Manufacturing of special industrial paper, High Filtration Efficiency Flame- Retardant Filter Paper is engineered to capture fine particulates while mitigating ignition risk in spark-prone environments. Typically formulated from cellulose and synthetic blends with specialty binders, the media integrates halogen-free flame-retardant chemistry and a graded pore structure to balance capture efficiency and airflow. Common configurable parameters include basis weight (60–220 gsm), thickness (0.3–1.2 mm), air permeability (80–300 L/m²·s), and efficiency classes aligned with ISO 16890 (e.g., ePM1/ePM2.5 ratings) or as prefilter layers for EN 1822/HEPA assemblies. Flame behavior is designed to meet stringent test regimes (e.g., UL 94 and relevant regional norms), supporting safer operation in dust collection, paint finishing, welding fume pre-stages, and battery manufacturing dry rooms.

- Relevance: It secures high particle retention at lower pressure drop, protecting downstream filters and process quality in paper converting, coating, laminating, and clean industrial environments.

- Technical background: Resin-impregnated, pleatable structures deliver mechanical strength, moisture resistance, and consistent pore size distribution, supporting stable service life and predictable ΔP.

- Manufacturer credibility: ANYA FILTER MEDIA CO., LTD provides tight quality control (ISO-based systems), application-specific compounding, and custom roll widths or die-cuts to streamline your production.

Benefits & Use Cases of High Filtration Efficiency Flame- Retardant Filter Paper in Manufacturing of special industrial paper

From process ventilation to dust collection, High Filtration Efficiency Flame- Retardant Filter Paper supports safer, cleaner production lines. In specialty paper mills and converters, it is used in prefiltration of HVAC for coating rooms, solvent or powder handling areas, and high-temperature zones near drying tunnels. In packaging and print facilities, it serves as a prefilter in paint and varnish booths, helping to reduce overspray carryover and protect downstream HEPA stages. Its flame-retardant design reduces the risk of ignition when sparks, hot particles, or static discharges occur in cutting, embossing, or sanding operations common to paper finishing and converting.

- Applications: Dust collectors for slitting and trimming, welding and grinding prefilters in maintenance shops, battery separator and electronics packaging clean zones, and turbine/compressor inlet prefilters in plant utilities.

- Competitive advantages: High dust-holding capacity, excellent pleat integrity, stable efficiency across load, and flame-retardant chemistry designed for compliance—driving longer service life and safer operation.

- Proven expertise: ANYA FILTER MEDIA CO., LTD tailors porosity, basis weight, and surface treatments (oleophobic/anti-static options) to your process, ensuring compatibility with pleating, potting, and frame assembly lines.

Cost, Maintenance & User Experience

Total cost of ownership depends on service life, energy consumption, and change-out labor. High Filtration Efficiency Flame- Retardant Filter Paper is engineered for low initial pressure drop and high dust-holding capacity—two factors that can reduce fan energy and extend intervals between replacements. When staged correctly (e.g., coarse prefilter → FR prefilter → fine/HEPA), many users report fewer unplanned shutdowns and more consistent differential pressure. For plants running 24/7, predictable ΔP translates into improved uptime and measurable ROI across quarters, not just weeks.

- Durability & ROI: Resin-impregnated, pleatable media resists mechanical stress and humidity swings common near dryers, helping maintain pleat geometry and sealing integrity—key to leakage prevention and yield protection.

- Maintenance guidance: Track terminal pressure drop per OEM recommendation, store rolls flat and dry, and ensure gasket compression to avoid bypass. With proper staging, facilities often extend change-out cycles while maintaining compliance.

Sustainability & Market Trends in manufacturing

Environmental expectations and safety regulations are reshaping filtration choices. Market adoption is shifting toward flame-retardant, halogen-free, low-emission filter papers that comply with ISO 16890 classification and align with NFPA guidance on combustible dust risk mitigation. Meanwhile, energy-efficient media that maintain lower pressure drop help plants cut Scope 2 emissions and operating costs. In high-value converting and coating lines, better prefiltration protects downstream HEPA, reducing waste and prolonging component lifetimes—key pillars of circularity and resource efficiency.

- Eco-forward design: ANYA FILTER MEDIA CO., LTD offers water-based impregnation options, halogen-free flame-retardant systems, and formulations engineered to be RoHS and REACH compliant, supporting your ESG commitments.

- Future-ready capability: With application engineering support and quality systems, ANYA anticipates tightening air quality standards and evolving safety codes—helping you qualify media faster and scale reliably.

Conclusion on High Filtration Efficiency Flame- Retardant Filter Paper from ANYA FILTER MEDIA CO., LTD

For manufacturers in the Paper and paper products industry, High Filtration Efficiency Flame- Retardant Filter Paper offers an optimal balance of safety, performance, and lifecycle value. By combining reliable particle capture with flame-retardant chemistry and robust pleatability, it safeguards product quality and uptime across demanding applications. Backed by the technical expertise of ANYA FILTER MEDIA CO., LTD, you gain a partner focused on customization, compliance, and supply continuity.

- Enhance safety, efficiency, and process stability with a proven specialty industrial paper solution.

- ANYA FILTER MEDIA CO., LTD stands for quality, responsiveness, and engineered performance.

- Strong CTA: Contact us: email: sales@anyafiltermedia.com — Visit our website: https://www.anyafiltermedia.com

Post time: Nov-14-2025