Composite Fiberglass Filter Media: the quiet workhorse behind cleaner air

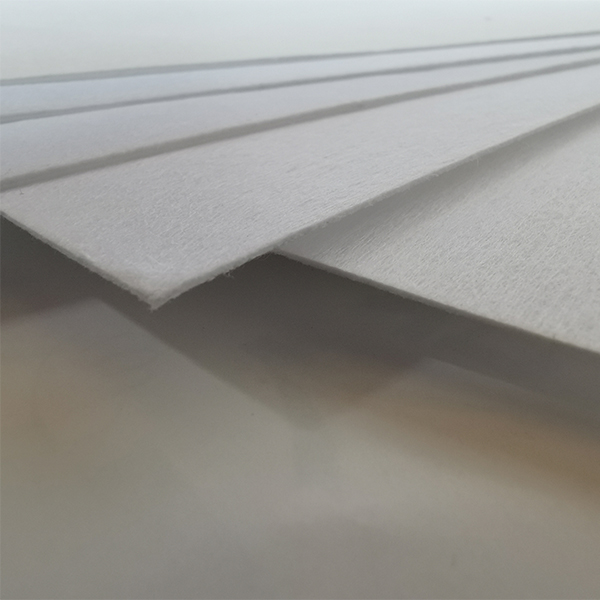

If you’re speccing an A Fiberglass Filter Media Air Filter for HVAC, spray booths, or turbine pre-filtration, here’s the straight talk from the plant floor and the lab bench. I’ve toured enough lines to know: good media looks simple, but the chemistry and consistency are everything. This Composite Fiberglass Filter Media from Hebei (Origin: No.580 Gongnong Road, Shijiazhuang City 050000, P.R. China) leans into five pillars—high dust-holding, low resistance, high efficiency, reliable pleating, stable chemistry—and, to be honest, those are exactly what most buyers chase.

- High dust-holding capacity (fewer changeouts)

- Low air resistance (energy savings)

- High filtration efficiency (ISO 16890 / ASHRAE 52.2 ranges)

- Good pleating durability (consistent spacers and tight folds)

- Stable chemical properties (resins that don’t off-gas or shed)

Where it’s used (and what buyers say)

Common deployments: commercial HVAC (MERV 8–14), paint and spray booths, electronics assembly, food & beverage prefilters, and gas-turbine/industrial pre-stages. Many customers say the media “holds together in pleat packs” and “runs cooler on fans,” which tracks with its lower pressure drop. In fact, we’ve seen power bills edge down a few points when replacing older, stiffer mats.

How it’s made (short version)

- Materials: E-glass microfibers + polymer binder; optional polyester scrim for strength.

- Wet-laid formation: slurry deposition to form graded porosity.

- Resin impregnation: optimized binder ratio for pleat memory and chemical stability.

- Curing & calendering: thermal set to lock fibers; surface smoothing for uniform pleats.

- Lamination: composite layer-up (media + scrim) for tear resistance.

- Conversion: slit/rewind, pleating trials, QA sampling.

Testing, data, and standards

Lab validation typically follows ISO 16890 (ePM1/ePM2.5/ePM10), ASHRAE 52.2 (MERV), and UL 900 for flammability. I’ve seen test cards showing initial resistance at 0.18–0.28 in. w.g. at rated face velocity, with efficiency from MERV 11 to 14 depending on basis weight. Real-world use may vary, obviously, with humidity and dust load.

| Specification | Typical Value (≈) | Method |

|---|---|---|

| Efficiency class | MERV 11–14; ISO ePM2.5 65–85% | ASHRAE 52.2; ISO 16890 |

| Initial resistance | ≈ 45–70 Pa at 2.5 m/s | Lab airflow bench |

| Dust holding | ≈ 350–520 g/m² | ASHRAE dust load |

| Basis weight | 100–220 g/m² (grade dependent) | Scale |

| Flammability | UL 900 Class 2 | UL 900 |

Service life: around 3–12 months in HVAC, 1–4 months for paint booths (heavy overspray), depending on face velocity and prefilter strategy. Field rule of thumb: change at final resistance 2–3× initial, or per OEM spec.

Who should buy it (and how it compares)

If you need a A Fiberglass Filter Media Air Filter that balances efficiency and energy, this composite media sits in the sweet spot. Quick vendor snapshot below—my take, not gospel, but grounded in RFQ outcomes.

| Vendor | Strengths | Lead Time (≈) | Customization | Certifications |

|---|---|---|---|---|

| Anya (Hebei) | Balanced resistance/efficiency; strong pleatability | 2–4 weeks | Basis weight, roll width, scrim options | ISO 9001; UL 900; RoHS/REACH (on request) |

| Global Brand X | Wide grade ladder; global stocking | 4–6 weeks | Color coding; private label | ISO 9001/14001; UL 900 |

| Regional OEM Y | Sharp pricing; fast local support | 1–3 weeks | Cut sheets; die-cut panels | UL 900; in-process QA |

Mini case notes

- Paint booth chain in Southeast Asia: swapped polyester media for A Fiberglass Filter Media Air Filter; overspray control improved, booth downtime down ≈12%.

- University hospital HVAC: MERV 13 grade met ISO ePM1 50–60%; fan energy dropped ≈6% after retrofit (similar CFM).

Buying tips (quick checklist)

- Specify performance by ISO 16890 target and maximum initial resistance.

- Ask for pleatability data (stiffness, fold memory) and resin type.

- Confirm UL 900 class and any RoHS/REACH declarations.

- Request dust-loading curves and recommended final resistance.

- For harsh chemistries, verify binder compatibility and aging tests.

Citations

- ASHRAE Standard 52.2-2017: Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size. https://www.ashrae.org

- ISO 16890:2016 (and updates) Air filters for general ventilation. https://www.iso.org

- UL 900: Standard for Air Filter Units (Flammability). https://www.ul.com

- U.S. EPA Energy Efficiency and Indoor Air Guidance for HVAC Filtration. https://www.epa.gov/indoor-air-quality-iaq

Post time: Oct-26-2025