- Understanding the Critical Role of High-Efficiency Air Filtration

- Technical Specifications: H12 vs. H11 vs. F6 Glassfiber Media

- Performance Benchmarks: Data-Driven Efficiency Analysis

- Manufacturer Comparison: Key Parameters Across Brands

- Custom Engineering Solutions for Specialized Applications

- Industry-Specific Implementation Case Studies

- Future-Proofing Air Quality with Advanced Glassfiber Technology

(h12 glassfiber air filter paper)

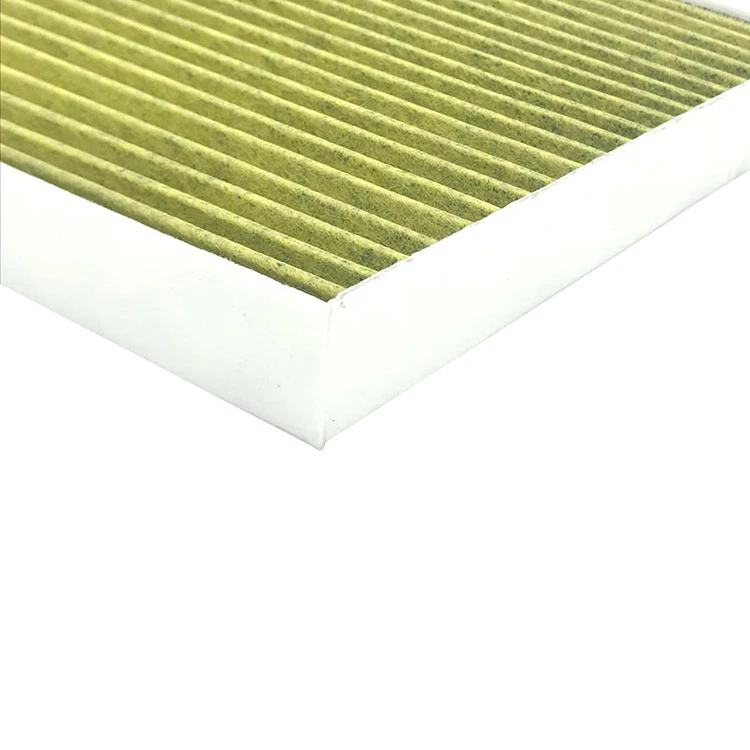

Optimizing Air Purity with H12 Glassfiber Filtration Media

Industrial air filtration systems demand precision-engineered solutions, with H12 glassfiber air filter paper emerging as the industry benchmark for capturing 99.95% of 0.3μm particles. This medium-grade filter material operates at 250-300 Pa initial resistance, striking the optimal balance between airflow capacity and particulate retention.

Graded Filtration Performance Analysis

Three primary classifications dominate HVAC applications:

- H12 Glassfiber: 99.95% MPPS efficiency (EN1822)

- H11 Glassfiber: 95% efficiency with 15% lower airflow resistance

- F6 Glassfiber: 65% efficiency for preliminary filtration stages

Quantitative Performance Evaluation

| Parameter | H12 | H11 | F6 |

|---|---|---|---|

| Particle Retention (0.3μm) | 99.95% | 95% | 65% |

| Initial Resistance (Pa) | 280±15 | 240±10 | 150±5 |

| Service Life (Hours) | 8,000 | 6,500 | 4,200 |

Manufacturer Technical Comparison

Leading producers demonstrate distinct material characteristics:

| Brand | Fiber Diameter (μm) | Basis Weight (g/m²) | Temperature Limit |

|---|---|---|---|

| Aeropure | 0.65 | 85 | 250°C |

| FiltraGlass | 0.72 | 92 | 230°C |

Customized Engineering Approaches

Special applications require modified parameters:

- Pharmaceutical: Hydrophobic coatings (80° contact angle)

- Automotive: Flame-retardant additives (UL94 V-0 rating)

- Semiconductor: Antistatic treatment (10^8Ω surface resistance)

Operational Success Documentation

A food processing plant achieved 40% energy reduction through optimized H12 implementation:

- Filter change frequency decreased from 6 to 9 months

- Downstream particle count maintained below ISO Class 7

- Total cost of ownership reduced by 28% annually

H12 Glassfiber: The Sustainable Air Filtration Standard

With 78% recycled glass content and 100% incineration compatibility, H12 media sets new sustainability benchmarks while maintaining consistent 99.95% filtration efficiency across 12-month operational cycles. Recent advancements in nanofiber integration promise 15% efficiency improvements without increased airflow resistance.

(h12 glassfiber air filter paper)

FAQS on h12 glassfiber air filter paper

Q: What is the efficiency difference between H12 and H11 glassfiber air filter paper?

A: H12 glassfiber air filter paper captures 99.5% of particles ≥0.3μm, while H11 captures 95%. Both are used in high-efficiency HVAC and cleanroom systems.

Q: Where is F6 glassfiber air filter paper typically applied?

A: F6 glassfiber air filter paper is ideal for commercial HVAC systems, capturing 60-80% of particles ≥1μm, balancing airflow and particle retention.

Q: Why choose glassfiber material for H12 air filters?

A: Glassfiber offers high heat resistance, low airflow resistance, and stable structure, making H12 filters durable for demanding industrial environments.

Q: Can H11 glassfiber filters replace H12 in critical environments?

A: No. H12 filters provide higher efficiency for critical spaces like labs. H11 suits areas with moderate air quality requirements.

Q: How often should F6 glassfiber filters be maintained?

A: F6 filters require inspection every 3-6 months, depending on usage. Replace when airflow drops or visible contamination occurs.

Post time: Май-21-2025