Understanding Phenolic Resin Filter Paper: Industry Trends and Technical Excellence

The global industrial filtration market continues its robust growth, driven by stringent environmental regulations, increasing demand for process efficiency, and advancements in material science. Within this dynamic landscape, resin filter paper stands out as a critical component, particularly the phenolic resin variant. This specialized filter media is engineered to meet the rigorous demands of various B2B applications, offering superior chemical resistance, thermal stability, and mechanical strength. Industry trends indicate a strong move towards enhanced efficiency, longer service life, and sustainable manufacturing practices, all areas where advanced phenolic resin filter solutions excel.

Key drivers for its adoption include the expanding petrochemical industry, the growing need for high-performance filtration in automotive and aerospace manufacturing, and the continuous innovation in fluid power systems. As industries strive for cleaner processes and reduced operational costs, the performance characteristics of resin filter paper become indispensable.

Detailed Process Flow: Manufacturing Phenolic Resin Filter Paper

The production of high-performance resin filter paper involves a meticulously controlled multi-stage manufacturing process, ensuring consistency, reliability, and optimal filtration characteristics. The core materials typically include high-purity cellulose fibers, synthetic fibers (e.g., glass fiber, polyester), and phenolic resin as the primary binder. This combination imparts the desired strength, porosity, and chemical resistance.

Manufacturing Stages:

-

Fiber Preparation and Pulping:

Selected raw fibers are carefully mixed and pulped to achieve a homogeneous slurry. This step ensures consistent fiber distribution and prevents agglomeration, which is critical for uniform pore structure. Mechanical refining techniques are often employed to optimize fiber length and fibrillation for improved bonding.

-

Web Formation (Paper Making):

The fiber slurry is then fed into a specialized paper machine, often using wet-laid processes similar to traditional papermaking. Here, the fibers interlock to form a coherent web, determining the initial basis weight and porosity. Advanced systems ensure uniform web thickness and density across the entire width.

-

Resin Impregnation (Casting/Coating):

This is a critical stage. The raw filter paper web is carefully impregnated with a liquid phenolic resin solution. Techniques like dip coating or spray coating are employed to ensure uniform saturation of the fibrous matrix. The resin acts as a binder, significantly enhancing the paper's mechanical strength, rigidity, thermal stability, and chemical resistance. Precision control over resin pick-up is vital to achieve specified parameters.

-

Curing and Drying:

After impregnation, the paper undergoes a controlled drying and curing process in high-temperature ovens. This stage polymerizes the phenolic resin, permanently binding the fibers and forming a rigid, robust filter medium. The curing profile (temperature, time) is precisely managed to achieve optimal physical properties without compromising the paper's inherent filtration capability.

-

Post-processing and Finishing:

The cured resin paper filter then undergoes various finishing operations, which may include calendering for controlled thickness and surface smoothness, slitting into specific widths, and packaging into rolls or sheets according to customer requirements. Quality checks are continuous throughout this stage.

Testing Standards and Quality Assurance:

Throughout the manufacturing process, strict adherence to international testing standards is maintained to guarantee product quality. This includes, but is not limited to, ISO 16889 for multi-pass testing (determining filtration efficiency and dirt-holding capacity), ASTM E1294 for pore size distribution, and various industry-specific standards for burst strength, tensile strength, and chemical compatibility. Our commitment to ISO 9001 certified quality management ensures every batch of resin filter paper meets the most demanding specifications.

Technical Specifications and Parameters

Phenolic resin filter paper is characterized by a suite of technical specifications that define its performance and suitability for specific applications. Understanding these parameters is crucial for engineers and procurement specialists selecting the optimal filtration media.

Typical Product Specifications (Phenolic Resin Filter Paper):

| Parameter | Value/Range | Measurement Standard |

|---|---|---|

| Basis Weight | 100 - 250 g/m² | ISO 536 / TAPPI T220 |

| Thickness | 0.3 - 0.8 mm | ISO 534 / TAPPI T411 |

| Air Permeability | 20 - 200 L/min/dm² @ 200Pa | ISO 9237 |

| Pore Size (Nominal) | 5 - 50 µm | ASTM F316 / ISO 4003 |

| Burst Strength | > 300 kPa | ISO 2758 / TAPPI T403 |

| Max. Operating Temp. | 135°C (275°F) continuous | Manufacturer's Test |

| Chemical Compatibility | Excellent with oils, fuels, coolants, mild acids, alkalis | ASTM D543 |

These specifications underscore the versatility and robustness of phenolic resin paper filter in demanding environments. Its controlled pore size distribution ensures efficient particle capture, while high burst strength guarantees structural integrity under pressure. The excellent thermal and chemical resistance makes it ideal for challenging industrial fluids.

Application Scenarios and Target Industries

The unique properties of phenolic resin filter paper make it indispensable across a multitude of industries where reliable fluid and air filtration is paramount. Its ability to withstand harsh operating conditions ensures extended service life and consistent performance.

Key Target Industries:

- Petrochemical and Chemical Processing: Filtration of process fluids, oils, and chemical intermediates where resistance to aggressive chemicals and high temperatures is crucial. This includes fuel filtration, hydraulic oil filtration, and various chemical separation processes.

- Automotive and Heavy Equipment: Used extensively in engine oil filters, fuel filters, and hydraulic filters for vehicles and machinery, ensuring protection against particulate contamination and extending component life.

- Industrial Machinery: Critical for lubricating oil and hydraulic fluid filtration in manufacturing equipment, CNC machines, and power generation systems to maintain operational efficiency and prevent downtime.

- Water Supply & Drainage: While less common for potable water, specialized resin filter papers are utilized in industrial wastewater treatment and process water purification systems requiring fine particulate removal and chemical stability.

- Metallurgy and Metalworking: Filtration of coolants, cutting fluids, and quench oils to remove metallic particles and extend fluid longevity, contributing to improved surface finish and tool life.

- Aerospace and Aviation: High-performance variants are used in aircraft hydraulic systems and fuel lines, where reliability and resistance to extreme conditions are non-negotiable.

Demonstrated Advantages in Typical Scenarios:

- Corrosion Resistance: In chemical processing, the phenolic resin matrix resists degradation from acids, alkalis, and solvents, ensuring filter integrity and preventing costly system contamination.

- Energy Saving: Optimized flow characteristics and high dirt-holding capacity lead to lower pressure drops across the filter, reducing the energy consumption of pumps and extending filter change intervals.

- Extended Service Life: The robust construction and chemical stability of resin filter paper result in significantly longer operational periods compared to conventional media, reducing maintenance costs and improving uptime.

- Enhanced Equipment Protection: Superior particle retention safeguards critical downstream components from wear and damage, prolonging the lifespan of machinery and reducing capital expenditure.

Technical Advantages and Vendor Comparison

Choosing the right supplier for resin filter paper is as crucial as selecting the right media itself. Our commitment to quality, innovation, and customer-centric solutions sets us apart.

Key Technical Advantages of Our Phenolic Resin Filter Paper:

- High Dirt-Holding Capacity: Our proprietary fiber blending and resin impregnation techniques create a filter matrix with a deep, tortuous path for superior contaminant capture without rapid pressure build-up.

- Exceptional Chemical Resistance: Formulated phenolic resin ensures integrity in the presence of challenging industrial fluids, preventing degradation and media migration.

- Superior Thermal Stability: Maintains structural integrity and filtration efficiency even at elevated operating temperatures, crucial for hot oil and hydraulic systems.

- Consistent Filtration Efficiency: Rigorous process control ensures uniform pore size distribution across the entire roll, delivering reliable and predictable filtration performance (e.g., Beta ratio > 1000 for specific grades).

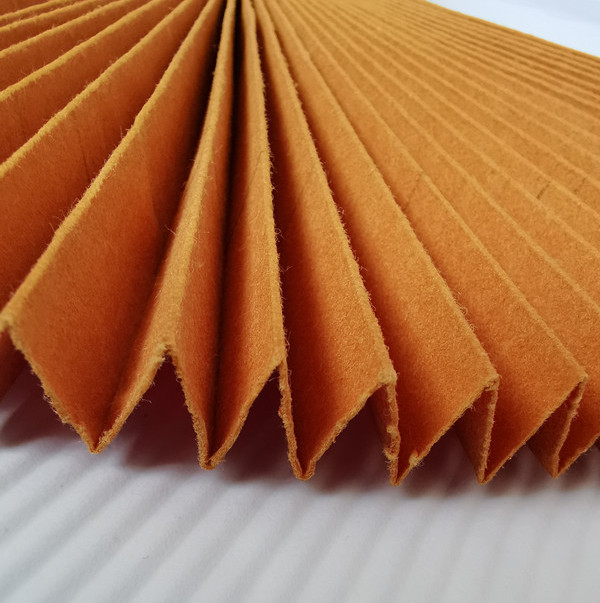

- Optimized Pleatability: Engineered for excellent pleat formation, maximizing surface area in filter elements and enhancing overall filter life and efficiency.

Vendor Comparison: Why Choose Anya Filter Media

| Feature/Aspect | Anya Filter Media | Competitor A (General) | Competitor B (Price-focused) |

|---|---|---|---|

| Product Quality & Consistency | Exceptional (ISO 9001 certified, rigorous QC) | Good, varies by batch | Acceptable, may have variations |

| Customization Capabilities | Extensive (fiber blends, resin types, pore sizes) | Limited standard options | Minimal, off-the-shelf only |

| Technical Support & Expertise | Dedicated R&D, application engineers | Standard technical data sheets | Basic product information |

| Lead Time & Reliability | Consistent & Punctual (avg. 3-4 weeks for standard orders) | Moderate, sometimes delays | Longer lead times, less reliable |

| Certifications & Compliance | ISO 9001, RoHS, REACH compliant | Basic industry standards | Minimal, focused on cost |

Our commitment to innovation and stringent quality control, backed by years of experience in the filtration industry, ensures that our phenolic resin filter paper not only meets but often exceeds industry benchmarks.

Customized Solutions and Application Case Studies

Recognizing that no two industrial applications are exactly alike, we offer extensive customization options for our phenolic resin filter paper. Our expert team collaborates closely with clients to develop tailored filtration media that address specific operational challenges and performance requirements.

Customization Capabilities:

- Fiber Blends: Custom combinations of cellulose, synthetic (e.g., glass, polyester, aramid), and specialty fibers to optimize strength, temperature resistance, and chemical compatibility.

- Resin Formulations: Tailored phenolic resin chemistries for enhanced resistance to specific chemicals, higher temperature tolerance, or specific mechanical properties.

- Pore Size & Permeability: Precision adjustments to achieve exact filtration efficiencies and flow rates, from coarse pre-filtration to fine particle capture.

- Basis Weight & Thickness: Customized specifications to fit unique filter element designs and performance targets.

- Surface Treatments: Optional surface modifications for properties like improved hydrophobicity or oleophobicity, catering to specific fluid separation needs.

Application Case Studies:

Case Study 1: Heavy Equipment Hydraulic System Filtration

A leading manufacturer of construction heavy equipment faced persistent issues with premature hydraulic component wear due to inefficient filtration in their high-pressure systems. Existing filter media failed to maintain adequate cleanliness levels under extreme operating temperatures and pressures, leading to frequent filter changes and unscheduled downtime.

- Solution: We developed a customized phenolic resin filter paper with a higher basis weight, optimized glass fiber content for enhanced rigidity, and a proprietary resin formulation for superior thermal stability and chemical resistance. The media's pore structure was fine-tuned for a Beta 70 = 1000 efficiency.

- Result: Post-implementation, the client observed a 40% increase in filter service life and a 60% reduction in hydraulic system component failures. ISO cleanliness codes improved from 22/20/17 to 18/16/13, resulting in significant operational cost savings and increased equipment reliability.

Case Study 2: Industrial Lubricant Filtration for CNC Machining

A large-scale precision CNC machining facility experienced issues with coolant and lubricant degradation due to micro-metallic particle accumulation, leading to decreased tool life and compromised surface finish on machined parts. Their existing cellulose-based filters saturated quickly and lacked the robustness for continuous high-flow applications.

- Solution: We provided a phenolic resin paper filter specifically designed for emulsion and oil filtration, featuring enhanced wet strength, superior dirt-holding capacity, and excellent resistance to machining coolants. The media's pleatability was also improved to maximize surface area within existing filter cartridges.

- Result: The client reported a 50% extension in coolant life, a 25% increase in tool life, and a noticeable improvement in surface finish quality. Filter replacement frequency was reduced by 35%, leading to substantial savings in consumables and maintenance labor.

Frequently Asked Questions (FAQ)

Q1: What are the primary advantages of phenolic resin filter paper over traditional cellulose media?

A1: Phenolic resin filter paper offers significantly enhanced chemical resistance, superior thermal stability, higher mechanical strength (especially wet strength), and often improved dirt-holding capacity. These properties lead to longer service life and more reliable performance in demanding industrial applications where traditional cellulose might degrade or fail.

Q2: Can your resin filter paper be customized for specific chemical compatibility requirements?

A2: Absolutely. We specialize in customizing the resin formulation and fiber blend to meet specific chemical compatibility needs. Our R&D team works with clients to analyze their fluid compositions and recommend or develop media that offers optimal resistance to acids, alkalis, solvents, and other aggressive chemicals.

Q3: What is the typical lead time for an order of phenolic resin filter paper?

A3: For standard product configurations, our typical lead time is 3-4 weeks from order confirmation to shipment. Custom orders may require additional time for material sourcing and process development, generally ranging from 5-8 weeks. We strive for efficient production and on-time delivery.

Q4: Do you offer samples for testing and evaluation?

A4: Yes, we provide samples of our standard and customized phenolic resin paper filter for client evaluation and testing. Please contact our sales team with your specific requirements, and we will arrange for sample delivery.

Q5: What is your warranty policy for resin filter paper products?

A5: We stand behind the quality of our products. Our phenolic resin filter paper is warranted to be free from defects in material and workmanship and to conform to the published specifications for a period of 12 months from the date of shipment, provided it is stored and used under recommended conditions. Please refer to our full warranty statement for detailed terms and conditions.

Trustworthiness and Support Information

Our Commitment to Quality and Service:

Anya Filter Media has been a trusted partner in industrial filtration for over 15 years, serving a global clientele that includes Fortune 500 companies in automotive, petrochemical, and manufacturing sectors. Our adherence to ISO 9001:2015 standards, alongside continuous investment in R&D, ensures that our phenolic resin filter paper and other filtration solutions meet the highest performance and reliability benchmarks. We regularly collaborate with leading academic institutions and industry bodies to stay at the forefront of filtration technology.

Lead Time and Fulfillment:

We maintain a robust supply chain and optimized production schedules to ensure consistent and timely delivery. For standard orders, typical lead times range from 3 to 4 weeks. For custom formulations or high-volume projects, our team works closely with clients to establish realistic and achievable fulfillment schedules, including options for expedited production where feasible.

Warranty Commitments:

All our phenolic resin filter paper products are backed by a comprehensive warranty, guaranteeing performance against specified technical parameters and freedom from manufacturing defects. This commitment underscores our confidence in our product quality and our dedication to customer satisfaction. Detailed warranty terms are available upon request and provided with every order.

Customer Support Information:

Our dedicated customer support and technical service teams are available to assist with product selection, application engineering, troubleshooting, and post-sales inquiries. We provide expert guidance to ensure optimal performance of our resin paper filter in your specific applications.

- Technical Support: techsupport@anyafiltermedia.com

- Sales Inquiries: sales@anyafiltermedia.com

- Phone: +1 (XXX) XXX-XXXX (Available Monday - Friday, 8:00 AM - 5:00 PM EST)

- Website: www.anyafiltermedia.com

References

- ISO 16889: Hydraulic fluid power – Filters – Multi-pass method for evaluating filtration performance of a filter element.

- ASTM F316: Standard Test Methods for Pore Size Characteristics of Membrane Filters by Bubble Point and Mean Flow Pore Test.

- TAPPI T403 om-02: Bursting Strength of Paper.

- Perry's Chemical Engineers' Handbook, 9th Edition. McGraw-Hill Education, 2018.

- Fluid Power Society, "Industrial Hydraulic Filtration Best Practices Guide," 2021.

Post time: Sep-22-2025