Phenolic Resin Filter Paper: what’s changing, what still matters

I spent a week in Hebei walking the line at a paper-impregnation plant and got hands-on with Resin Filter Paper—specifically, phenolic resin–impregnated oil filter media used across automotive and industrial engines. The short version? Quality has quietly improved, while pricing hasn’t blown up (yet). In fact, most of the innovation is hiding in fiber blends and curing profiles rather than flashy marketing.

Where it’s used (and why it works)

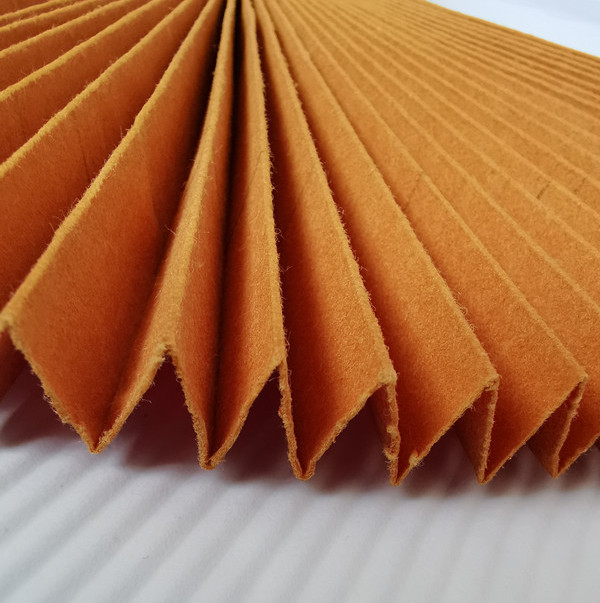

You’ll find Resin Filter Paper pleated inside spin-on and cartridge oil filters for passenger cars, light trucks, ag and construction equipment, as well as compressors and small gensets. Phenolic resin brings thermal stability, wet strength, and pleat rigidity—so filtration stays consistent even when oil is hot, dirty, and full of soot. Many buyers tell me they switched from plain cellulose after noticing better collapse resistance during cold starts.

Process flow (shop-floor view)

Materials: refined cellulose fiber with optional synthetic reinforcement (PET or rayon), phenolic resin (novolac/hexamine), release agents, and anti-wicking additives.

Methods: wet-forming → base paper drying → online impregnation (target resin pickup) → double-stage curing at ≈150–180°C → calendering/creping for pleatability → slitting/rewind → QC.

Testing: TAPPI basis weight/thickness/tensile; Gurley air resistance; burst strength; resin content; ISO 4548-12 particle efficiency on pleated packs; occasionally ISO 16889 multipass for beta ratios.

Service life: in real fleets, 8,000–15,000 km for passenger cars, or ≈250–500 hours for off-road. Of course, duty cycle and soot loading change everything.

Product specifications (typical, lab data vs. real-world may vary)

| Basis weight | ≈140 ±10 g/m² (TAPPI T410) |

| Thickness | ≈0.45 ±0.05 mm (TAPPI T411) |

| Resin content | 18–25% (calc. LOI) |

| Mean pore size | ≈18–24 μm |

| Air resistance | Gurley 12–25 s/100 ml (TAPPI T460) |

| Burst strength | ≈260–320 kPa |

| Wet tensile (MD/CD) | ≈30/15 N per 15 mm (TAPPI T494) |

| Efficiency | β20 ≥ 75 (≈98.7%); β30 ≥ 200 on pleated elements |

Customization and compliance

Need something tweaked? Resin Filter Paper can be tuned for basis weight, resin %, crepe ratio, color coding, anti-drainback wettability, even synthetic fiber blends for high-soot diesel. Certifications commonly offered: ISO 9001 and IATF 16949 for automotive QMS. Many customers ask for PPAP packs and traceability—available on request.

Vendor snapshot (buyer’s quick look)

| Vendor | Origin | Resin type | Lead time | Certs | Notes |

|---|---|---|---|---|---|

| Anya Filter Media | No.580 Gongnong Road, Shijiazhuang, Hebei, China | Phenolic (novolac) | 2–4 weeks | ISO 9001, IATF 16949 | Strong pleat stability, flexible MOQ |

| Vendor B (EU) | EU | Phenolic/melamine | 4–6 weeks | ISO 9001 | Premium pricing, stable supply |

| Vendor C (US) | USA | Phenolic | 3–5 weeks | ISO 9001 | Great tech support, higher MOQs |

Field feedback and mini case studies

Fleet A (city buses, diesel): switching to Resin Filter Paper with β20 ≥75 cut iron wear counts ≈12% over 6 months; oil change interval kept constant. Maintenance lead said pleats “kept shape even after thermal cycling.”

Ag co-op (tractors): reported fewer cold-start pressure spikes (estimated by delta-P logs). To be honest, not dramatic—but fewer bypass events is real money in uptime.

Buying tips

- Match Gurley and pore size to the engine family’s target delta-P curve.

- Ask for ISO 4548-12 efficiency curves on the finished pleated element, not just flat-sheet data.

- Request aging tests: 24–72 h hot oil soak, then burst and tensile re-checks.

- If you pleat deep, confirm crepe ratio and spring-back after oven cure.

Sources and standards:

- ISO 4548-12: Oil filters—Filtration efficiency using particle counting. https://www.iso.org

- ISO 16889: Hydraulic filters—Multipass method for evaluating filtration performance. https://www.iso.org

- TAPPI T410, T411, T460, T494—Paper testing methods. https://www.tappi.org

- IATF 16949: Automotive QMS requirements. https://www.iatfglobaloversight.org

Post time: Oct-25-2025