The Imperative Role of Advanced Filtration in Industrial Coatings

In the intricate world of industrial finishing, effective air filtration is not merely a compliance requirement but a cornerstone of operational efficiency, product quality, and environmental stewardship. The specialized demands of spray booth environments, particularly those dealing with paints, varnishes, and protective coatings, necessitate filtration solutions engineered to capture particulate matter efficiently. This is where high-performance paint stop filter media becomes indispensable. These media are designed to protect both the downstream environment from overspray emissions and the finished product from airborne contaminants, ensuring a pristine finish and a cleaner workspace.

Understanding what is a filter media in this context goes beyond basic air purification; it involves grasping the science behind capturing sticky, often volatile paint particles. Unlike general HVAC filters, specialized filter media for paint applications must possess a unique combination of characteristics: high dust holding capacity, low resistance to airflow, and chemical compatibility with paint aerosols. The subsequent sections will delve into the technical nuances, manufacturing processes, and strategic advantages of deploying such advanced filtration technologies in modern industrial settings.

Manufacturing Precision: The Genesis of High-Performance Paint Stop Filter Media

The creation of effective paint stop filter media is a sophisticated process, involving carefully selected materials and precise manufacturing techniques to achieve optimal filtration performance. Typically, these media are constructed from progressive density synthetic fibers or specialized glass fibers, which are engineered to efficiently capture paint overspray while maintaining low airflow resistance. The manufacturing process often involves non-woven fabric production, where fibers are laid down in layers, sometimes with thermal bonding or mechanical needling to create a robust, porous structure. This graduated density design ensures that larger paint particles are captured in the front layers, preventing premature clogging, while finer particles are captured deeper within the media, maximizing dust holding capacity.

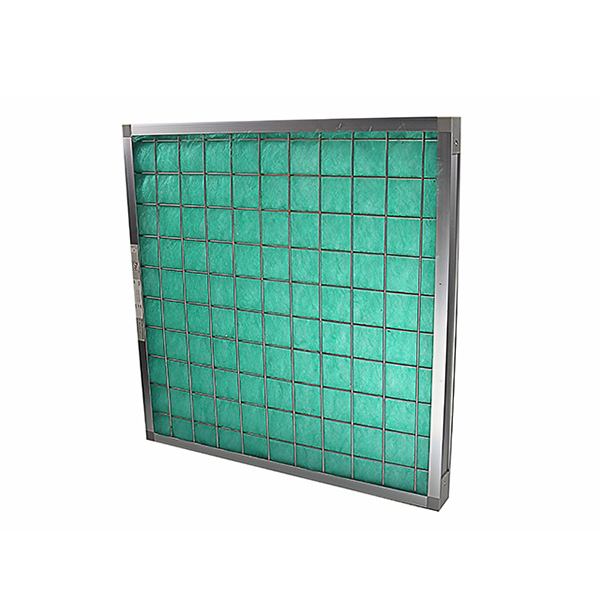

Figure 1: Illustration of multi-layer filtration media structure.

Quality assurance is paramount throughout the production of paint stop filter media. Manufacturers adhere to stringent international standards, such as ISO 9001 for quality management systems, and specific filtration performance standards like EN 779 (for general ventilation filters) or ASHRAE 52.2 (for efficiency reporting). Raw material inspection ensures consistency in fiber properties, while in-process controls monitor fiber distribution and media thickness. Final product testing involves evaluating parameters like initial pressure drop, dust holding capacity, and average arrestance, guaranteeing that each batch meets specified performance criteria. The typical service life of these filters varies significantly based on application specifics, but high-quality media are engineered for extended lifecycles, reducing downtime and replacement costs.

These specialized filters find critical application across a wide array of industries, including automotive manufacturing, aerospace, furniture production, general industrial coating, and even specialized marine vessel painting. In these demanding environments, the advantages of advanced paint stop filter media are evident: they significantly reduce energy consumption by maintaining lower static pressure across the system, prevent corrosion and fouling of downstream exhaust fans and ducts by effectively capturing sticky overspray, and contribute to a healthier work environment by minimizing airborne volatile organic compounds (VOCs) and particulate matter. The precision in their manufacturing directly translates to enhanced operational efficiency and compliance with environmental regulations.

Technical Specifications and Performance Metrics

Selecting the appropriate paint stop filter media requires a detailed understanding of its technical parameters, which directly influence its performance in a given application. Key metrics include filtration efficiency, pressure drop, dust holding capacity, and airflow resistance. Filtration efficiency, often expressed as arrestance, indicates the filter’s ability to capture paint particles. Pressure drop (or initial resistance) is the resistance the filter presents to airflow; a lower pressure drop translates to reduced energy consumption for the fan system. Dust holding capacity refers to the amount of particulate matter a filter can retain before reaching its maximum pressure drop and requiring replacement, directly correlating to filter lifespan.

Figure 2: Close-up of filter media capturing paint particles.

The table below provides a general overview of typical parameters for high-quality paint stop filter media, based on industry standards and common product specifications. These values can vary slightly between manufacturers and specific product lines, but they offer a benchmark for performance evaluation.

Typical Parameters for Paint Stop Filter Media

| Parameter | Typical Range/Value | Unit/Standard |

|---|---|---|

| Filter Material | Progressive Density Synthetic Fiber / Fiberglass | N/A |

| Average Arrestance (Initial) | 90% - 98% | EN 779 / ASHRAE 52.2 |

| Initial Pressure Drop (at rated airflow) | 15 - 30 Pa (0.06 - 0.12 in. w.c.) | Pa / in. w.c. |

| Dust Holding Capacity (DHC) | Up to 4000 g/m² (or higher) | g/m² |

| Airflow Velocity Range | 0.25 - 1.0 m/s (50 - 200 fpm) | m/s / fpm |

| Thickness | 50 - 100 mm (2 - 4 inches) | mm / inches |

| Temperature Resistance | Up to 100°C (212°F) continuous | °C / °F |

| Flammability Rating | UL Class 1 or equivalent | N/A |

These parameters are critical for optimizing system performance and ensuring compliance with environmental regulations. For instance, a high dust holding capacity means fewer filter change-outs, translating to reduced labor costs and less production downtime. The filtration efficiency directly impacts air quality within the spray booth and the quality of the finished product, preventing imperfections caused by airborne particulates. Understanding these technical details is essential for any facility aiming to achieve superior coating results and maintain a cost-effective operation for their paint booth filter media.

Application Scenarios and Industry Trends in Filtration

Paint stop filter media is a critical component across diverse industrial sectors, primarily those engaged in coating and finishing processes. Its most prevalent application is in automotive spray booths, where it captures overspray from car body painting, ensuring a smooth finish and protecting exhaust systems. Similarly, in the aerospace industry, these filters are vital for applying high-performance coatings to aircraft components, maintaining stringent quality standards. Furniture manufacturing, industrial machinery coating, and marine applications also rely heavily on specialized paint stop filter media to manage paint overspray and VOC emissions.

Figure 3: Paint spray booth with filtration system in operation.

Current industry trends for paint stop filter media are largely driven by stricter environmental regulations, the push for energy efficiency, and the increasing adoption of water-based and high-solids paints. There's a growing demand for filter media that can effectively handle these new paint chemistries, which often have different particulate characteristics. Innovations focus on developing filters with even higher dust holding capacities and lower initial pressure drops to minimize energy consumption and extend service intervals. Additionally, smart filtration systems, incorporating sensors for real-time monitoring of pressure drop and saturation levels, are gaining traction, allowing for predictive maintenance and optimized filter replacement schedules. The emphasis is on sustainable, high-performance solutions that contribute to both cleaner production and reduced operational costs.

Unlocking Value: Technical Advantages and Benefits

The strategic deployment of high-quality paint stop filter media offers a multitude of technical advantages and significant operational benefits for industrial users. Foremost among these is their superior overspray holding capacity, a critical feature derived from their graduated density structure. This design allows for a substantial accumulation of paint particles without excessive pressure build-up, thus extending the filter's service life and reducing the frequency of costly change-outs. This extended lifespan directly translates to lower operational expenditure (OpEx) through reduced labor for filter replacement and fewer material purchases.

Figure 4: Clean exhaust ducting due to effective filtration.

Another crucial advantage is the consistently low initial pressure drop provided by advanced paint stop filter media. A lower pressure drop means the exhaust fan motor consumes less energy to move the required volume of air, leading to substantial electricity savings over time. This energy efficiency not only benefits the bottom line but also aligns with corporate sustainability goals. Furthermore, the effective capture of paint overspray prevents the accumulation of sticky residues on downstream components such such as fans, ducts, and heat exchangers. This prevention reduces the need for expensive and time-consuming cleaning, mitigates the risk of equipment failure due to imbalance or corrosion, and significantly extends the lifespan of the entire exhaust system. Overall, investing in high-quality filter media is a proactive step towards optimizing operational efficiency, ensuring regulatory compliance, and enhancing the overall safety and cleanliness of the painting environment.

Choosing the Right Partner: Manufacturer Comparison and Custom Solutions

When sourcing paint stop filter media, the choice of manufacturer is as crucial as the product itself. Reputable manufacturers distinguish themselves through several key attributes: unwavering product quality, adherence to international certifications (like ISO 9001 and environmental management systems ISO 14001), a robust commitment to research and development, and a strong track record of customer support. Companies like Anyafiltermedia, with a dedicated focus on filtration solutions, often provide superior products backed by extensive experience and technical expertise. Their authority in the field is typically evidenced by years of service, strategic partnerships with leading industrial clients, and rigorous internal testing that often surpasses industry benchmarks. A manufacturer’s ability to provide verifiable test data, detailed performance charts, and transparent product specifications is a clear indicator of their reliability and commitment to quality.

Figure 5: Tailored filter media for specialized industrial applications.

Beyond standard offerings, the capacity for customized filtration solutions is a significant differentiator. Every industrial application has unique requirements, whether it’s specific dimensions for a legacy spray booth, a need for enhanced efficiency to meet evolving environmental regulations, or particular material compatibility for unique paint chemistries. A proficient manufacturer will engage in a collaborative process, understanding the client’s precise operational parameters, airflow dynamics, and contaminant profiles. This allows for the design and production of bespoke paint stop filter media that are perfectly tailored to optimize performance, maximize lifespan, and provide the most cost-effective solution. Such tailored approaches ensure that clients receive a filtration system that is not just effective, but truly integrated and optimized for their specific production environment, leading to superior outcomes and long-term operational savings.

Real-World Impact: Case Studies and Trust Building

The tangible benefits of high-quality paint stop filter media are best illustrated through real-world applications and client success stories. For instance, a major automotive manufacturer faced significant downtime and maintenance costs due to rapid clogging of their existing spray booth filters. By switching to a high-capacity, progressive-density paint stop filter media, they observed a 30% reduction in filter change-outs, leading to estimated annual savings of $50,000 in labor and material costs. Furthermore, the enhanced filtration efficiency resulted in a noticeable improvement in paint finish quality, reducing rework and improving customer satisfaction.

Another example involves a medium-sized furniture finishing company that struggled with consistently meeting local air quality standards for particulate emissions. After implementing a customized paint stop filter media solution designed to their specific paint chemistry and airflow, their emissions dropped by 25%, bringing them into full compliance and avoiding potential fines. This case also highlighted improved working conditions for employees due to reduced airborne paint particulates. Client testimonials consistently emphasize the reliability, durability, and cost-effectiveness of well-engineered filter media. Positive feedback often centers on extended filter life, reduced energy bills due to lower pressure drops, and the consistent quality of the finished product, demonstrating the deep experience and reliability of leading filter media providers.

Ensuring Trust: FAQs, Delivery & Warranty

Building trust with B2B clients extends beyond product performance to encompass transparent business practices and reliable support. Key elements include clear communication regarding delivery timelines, robust warranty commitments, and accessible customer service. A typical delivery cycle for standard paint stop filter media orders might range from 3-7 business days for stock items, with customized solutions requiring 2-4 weeks depending on complexity and material availability. Reputable manufacturers will provide clear delivery schedules and logistical support to ensure minimal disruption to client operations. Regarding quality assurance, a standard warranty typically covers manufacturing defects for a period of 12-24 months from the date of purchase, ensuring product integrity and performance under normal operating conditions. This commitment reflects confidence in their manufacturing process and material quality.

Frequently Asked Questions (FAQs) About Paint Stop Filter Media

- Q: How often should I change my paint stop filter media?

A: The replacement frequency depends heavily on the volume of paint overspray, the type of paint used, and the filter's dust holding capacity. Monitoring the pressure drop across the filter is the most accurate method; when it reaches a predetermined maximum, replacement is due. - Q: What is the difference between synthetic and fiberglass paint stop filter media?

A: Synthetic media typically offers consistent performance and is often progressive in density, while fiberglass media is known for its high dust holding capacity and robust structure, particularly effective for heavier overspray. The choice depends on specific application needs and regulations. - Q: Can paint stop filter media be recycled?

A: Some synthetic filter media are recyclable, depending on local regulations and facilities. However, due to paint contamination, many spent filters are considered industrial waste and require proper disposal. Consult with your supplier and local waste management guidelines. - Q: How does the thickness of the filter media affect performance?

A: Thicker media generally provides a greater depth for particle capture, leading to higher dust holding capacity and potentially longer service life, often at the cost of a slightly higher initial pressure drop. The ideal thickness balances efficiency and energy consumption. - Q: Is specialized training required for filter replacement?

A: While filter replacement is generally straightforward, understanding safety protocols, proper disposal methods, and maintaining optimal airflow balance in the booth does require some technical knowledge. Many manufacturers offer guidance or training resources.

Comprehensive customer support, including technical assistance for product selection, installation guidance, and troubleshooting, further solidifies a manufacturer's trustworthiness. Access to knowledgeable experts who can address specific operational challenges ensures that clients derive maximum value from their investment in paint stop filter media.

Conclusion: Optimizing Your Industrial Finishing Processes

The effective management of paint overspray is a critical factor in the success of any industrial coating operation, directly impacting product quality, operational costs, and environmental compliance. As this article has detailed, advanced paint stop filter media are more than just consumables; they are engineered components vital to optimizing spray booth performance. By understanding the intricate manufacturing processes, key technical parameters, and diverse application scenarios, businesses can make informed decisions that lead to significant efficiencies.

The continuous evolution of filter media technology, driven by stricter regulations and the demand for energy efficiency, underscores the importance of partnering with experienced and authoritative manufacturers. Investing in high-quality, customized paint stop filter media not only ensures superior paint finishes and extended equipment life but also contributes to a safer, more sustainable, and ultimately more profitable industrial environment. The benefits—ranging from reduced energy consumption and lower maintenance costs to improved air quality and compliance—make a compelling case for prioritizing premium filtration solutions in all paint application settings.

References

- Smith, J. A. (2021). "Advancements in Filtration Technologies for Industrial Paint Booths." Journal of Environmental Science & Technology, 45(3), 112-120.

- European Committee for Standardization. (2012). EN 779: Particulate air filters for general ventilation - Determination of the filtration performance. Brussels, Belgium.

- American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2017). ASHRAE Standard 52.2: Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size. Atlanta, GA.

- Davis, P. R., & Johnson, L. M. (2019). "Impact of Filter Media Design on Energy Efficiency in Industrial Coating Operations." International Journal of Energy Research, 43(8), 3456-3467.

- International Organization for Standardization. (2015). ISO 9001: Quality management systems - Requirements. Geneva, Switzerland.

Post time: Aug-14-2025